Tea rolling device

A kneading device and technology for tea leaves, applied in the direction of tea processing before extraction, can solve the problems of irregular shape, different tea products, and more broken tea, and achieve the effect of avoiding falling, good quality, and reducing broken tea.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

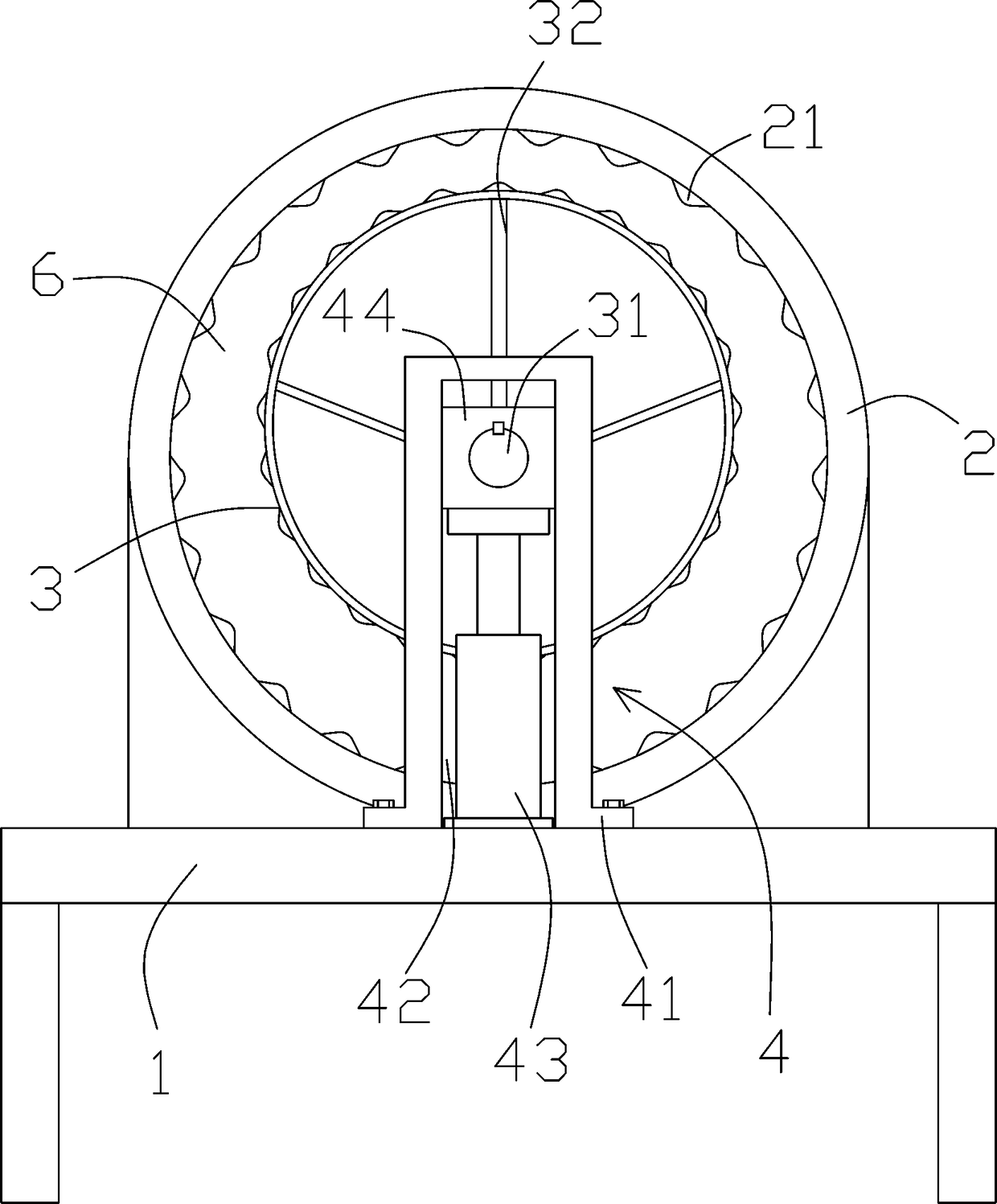

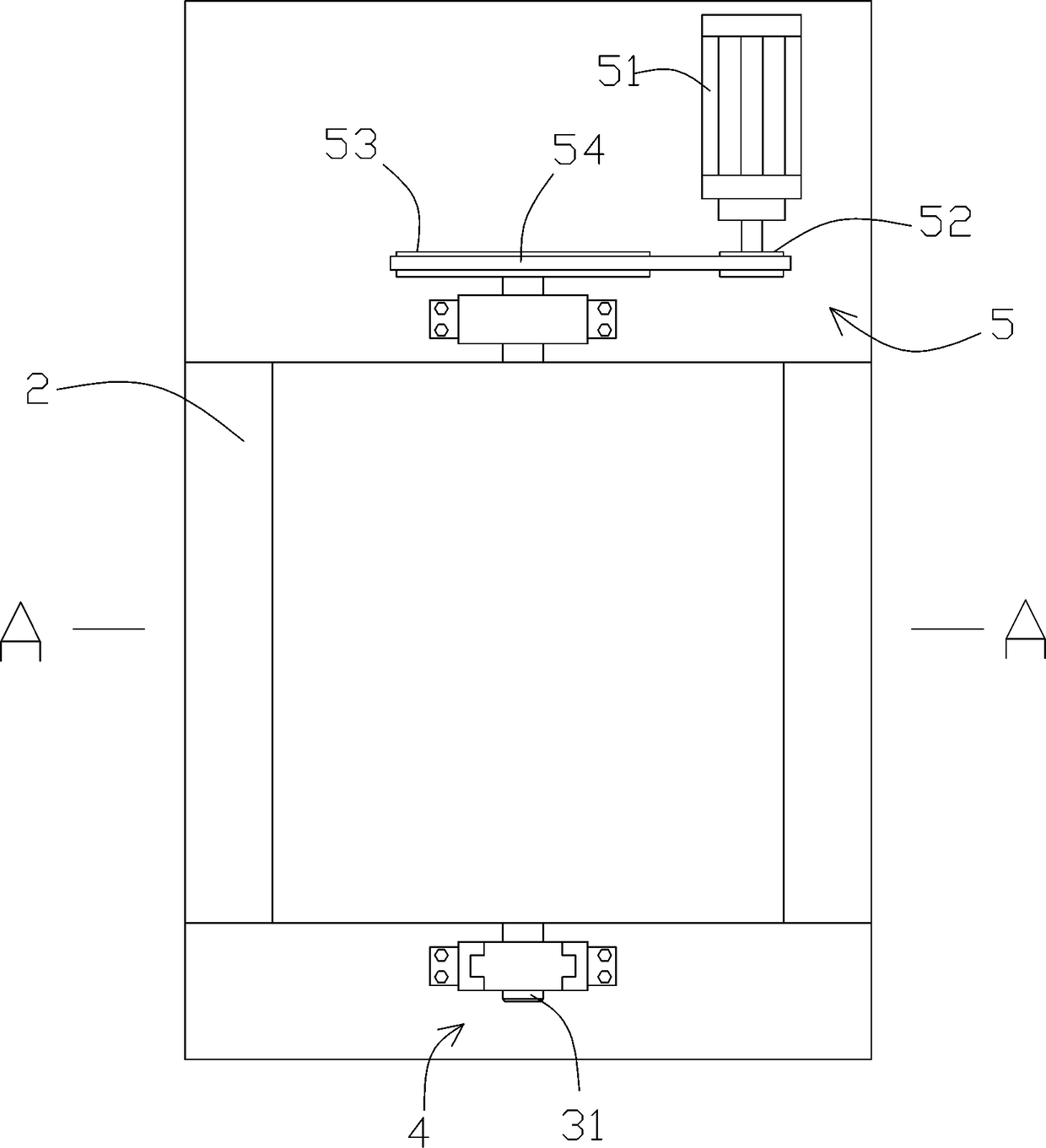

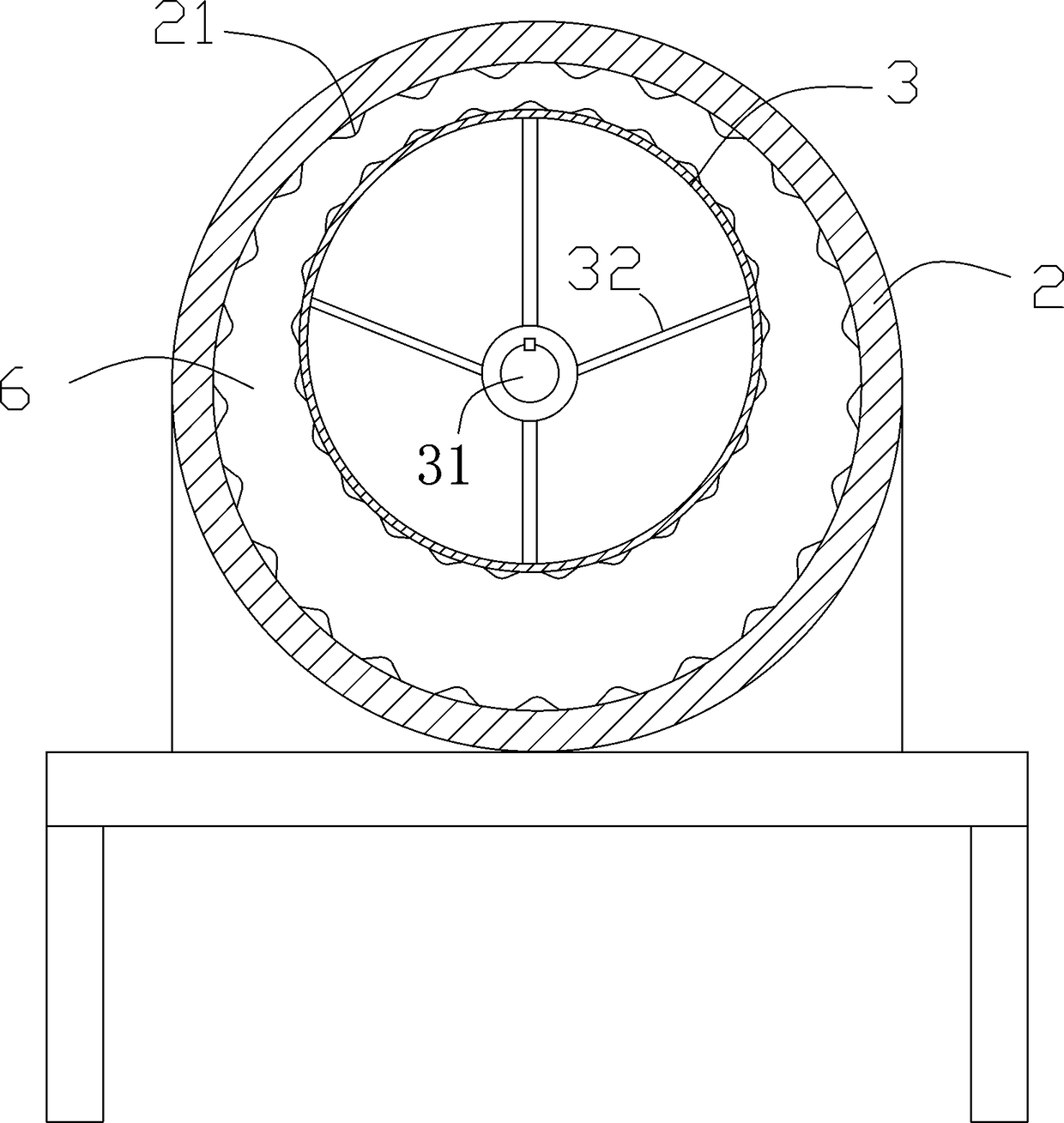

[0018] Such as Figures 1 to 4 Shown, a kind of tea kneading device comprises base 1, is fixed with kneading tube 2 on base 1, is provided with kneading roller 3 in kneading tube 2, kneading roller 3 has a rotating shaft 31, and rotating shaft 31 axes and kneading roller 3 The axes do not overlap, and the two ends of the kneading tube 2 are respectively provided with bearing seats 4, and the two ends of the rotating shaft 31 are respectively installed in the two bearing seats 4, and a driving device 5 is also included, and the driving device 5 is connected to the rotating shaft 31 by transmission. An annular kneading cavity 6 is formed by the inner wall surface of the kneading tube 2 and the outer wall surface of the kneading roller 3; wherein the axis of the rotating shaft 31 and the axis of the kneading tube 2 are on the same vertical plane;

[0019] A plurality of kneading ribs 21 are arranged on the inner wall of the kneading tube 2, and each kneading rib 21 is evenly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com