Rice milling device for fresh rice mill

A technology of fresh rice and rice milling rollers, which is applied in the directions of grain processing, application, and grain pod removal, which can solve the problems of low device reliability, energy consumption, and labor, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

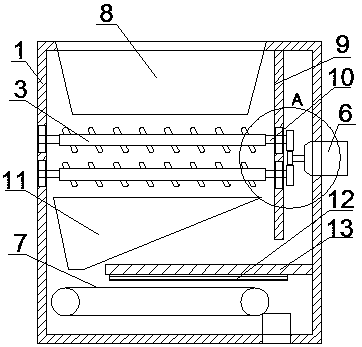

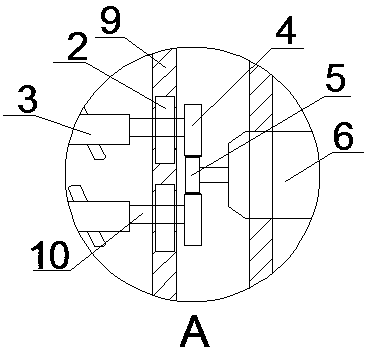

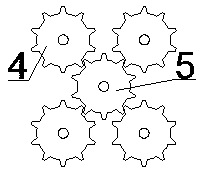

[0018] Such as Figure 1~3 As shown, a rice milling device for a fresh rice machine includes a housing 1, a bearing 2, a rice milling roller 3, a gear A4, a gear B5, a motor A6 and a grinding belt 7, and the upper part of the housing 1 is provided with a feed hopper 8. A support plate 9 is connected to the inner side of the top plate of the housing 1, and the support plate 9 is parallel to the left side plate of the housing 1. There are symmetrical support holes on the left side plate of the housing 1 and the support plate 9, and the housing The support holes on the left side plate of the body 1 and the support plate 9 are provided with four, and are distributed in a matrix. Bearings 2 are installed in the support holes, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com