An upright lamp disc seat screw assembly tool

A technology for assembling tooling and disc seats, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of glue outflow, time-consuming and labor-intensive, time-consuming and labor-intensive efficiency, etc., to achieve high repeatability and consistency, reduce labor Cost and effect of reducing rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

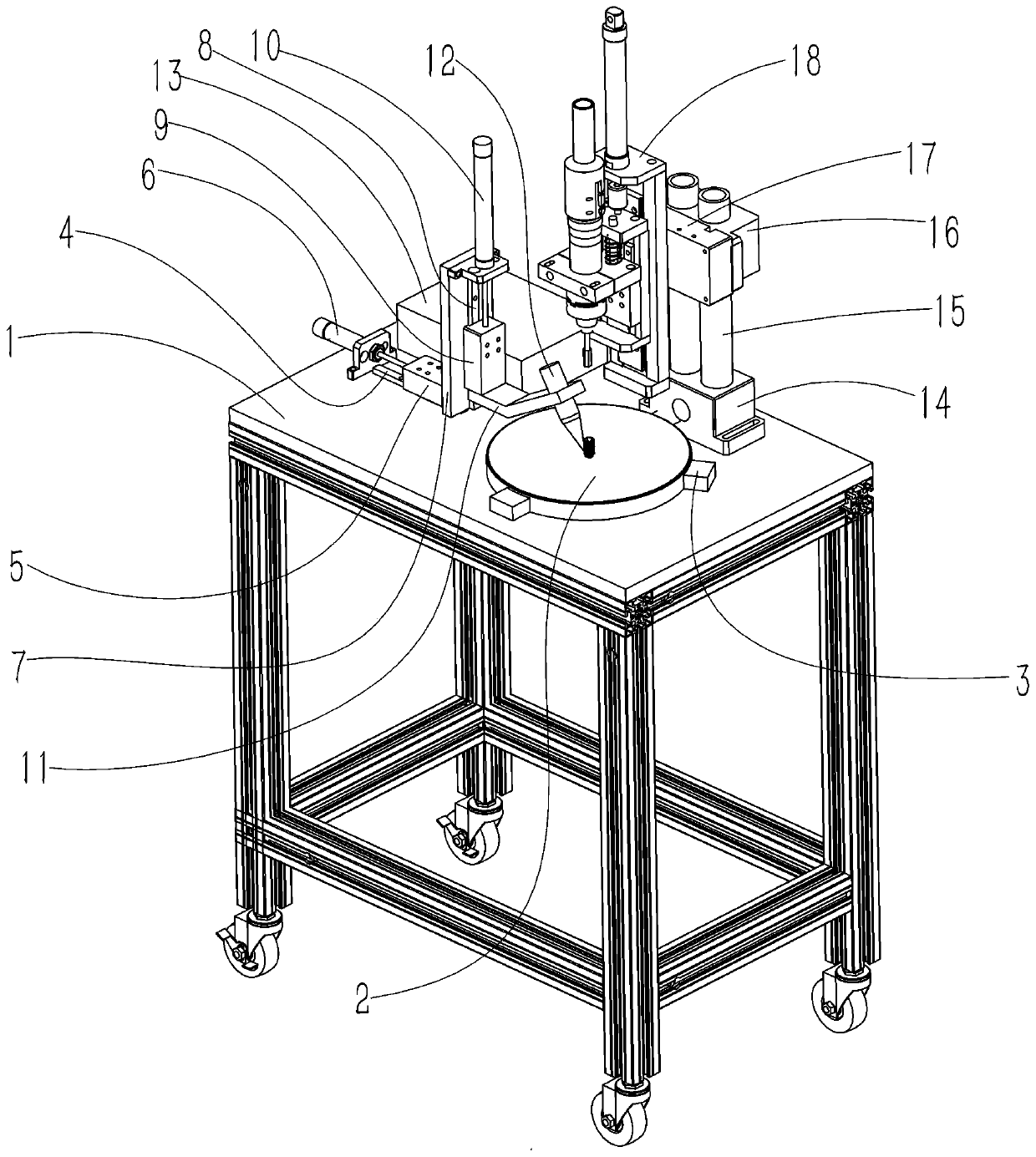

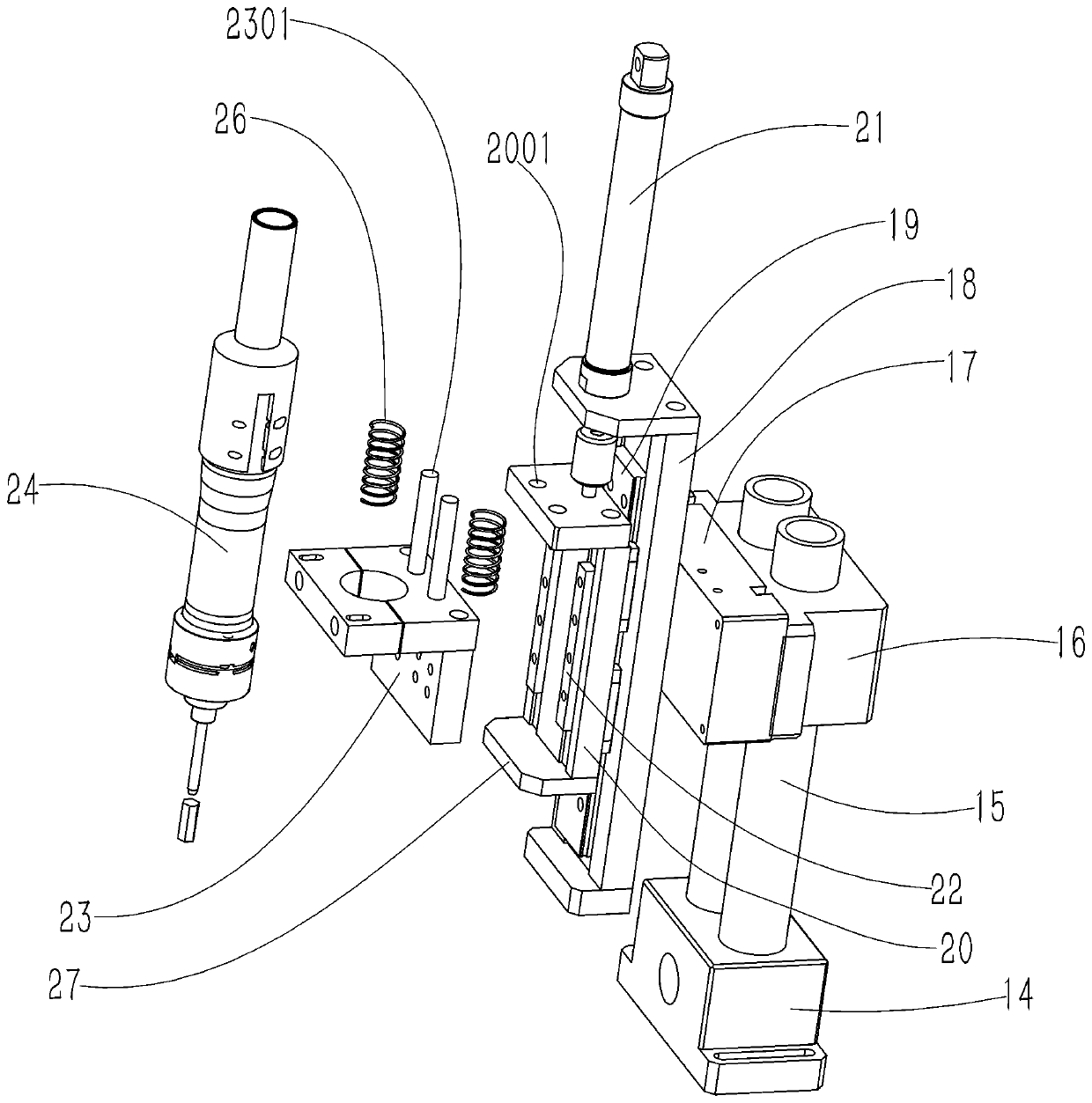

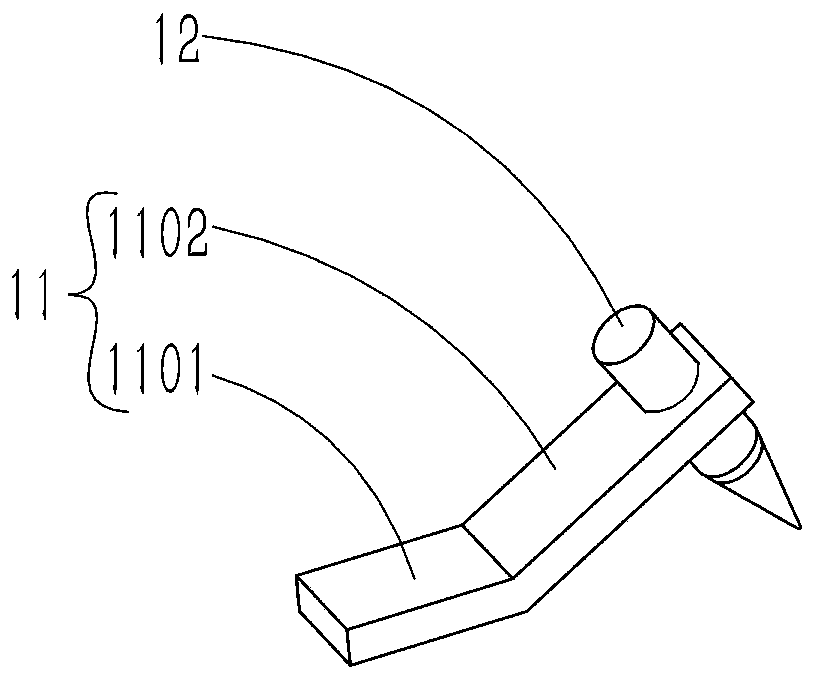

[0026] see Figure 1-5 , the present invention provides a technical solution: an upright lamp disc seat screw assembly tool, including a base 1, and a screw tightening mechanism and a glue dispensing mechanism arranged on the base 1, and the base 1 is provided with There are a plurality of clamping blocks 3 for clamping the disc seat 2; the dispensing mechanism includes a horizontal slide rail 4 arranged on the base 1, and the length direction of the horizontal slide rail 4 points to the disc The center of circle of the seat 2, the horizontal slide rail 4 is slidably connected with a horizontal slide block 5, and one end of the horizontal slide rail 4 on the base 1 is provided with a cylinder a 6 that promotes the movement of the horizontal slide block 5; On the horizontal slider 5, a vertical plate 7 is fixedly installed by bolts, a vertical slide rail 8 is installed on the vertical plate 7, and a vertical slide block 9 is slidably connected on the vertical slide rail 8. On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com