Automatic paper board folding machine

An automatic machine and cardboard technology, applied in the direction of folding thin materials, object supply, pile separation, etc., can solve cumbersome and inefficient problems, achieve the effects of improving product yield, preventing impact extrusion deformation, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will describe in detail with reference to the accompanying drawings in conjunction with the embodiments, so as to further explain the technical features and advantages of the present invention.

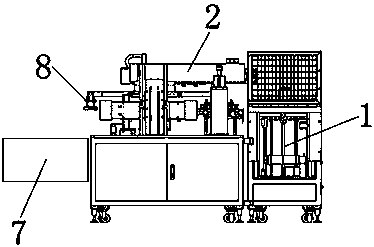

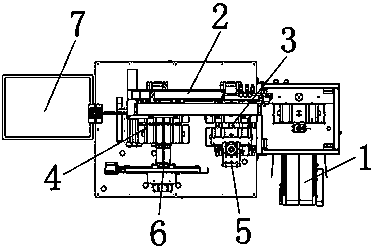

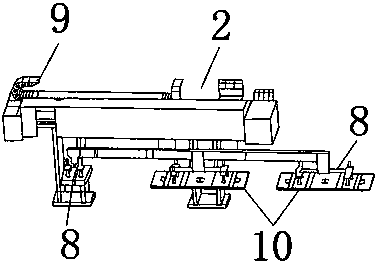

[0024] Such as Figure 1-6 As shown, a folding cardboard automatic machine of the present invention includes a feeding mechanism 1 and a transfer and grab mechanism 2. The transfer and grab mechanism 2 is connected to the crease deepening mechanism 5 through the first displacement mechanism 3, and the transfer and grab mechanism The mechanism 2 is connected to the folding mechanism 6 through the second displacement mechanism 4, and the lower part of the end of the transfer and grab mechanism 2 is provided with a material receiving port 7. The described feeding mechanism 1 is conveyed by rollers and the cylinder lifts the cardboard 10, and the described transfer and grab The mechanism 2 has a built-in crawler belt 9, and a plurality of pneumatic suction cups 8 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com