Hanging-type iron with horizontal glass heating pipes for heating

A technology of heating tubes and garment steamers, applied in the field of garment steamers, can solve the problems of uneven heating and heating, long waiting time, affecting service life, etc., and achieve the effects of stable steam output, reduced volume and weight, and fast steam output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

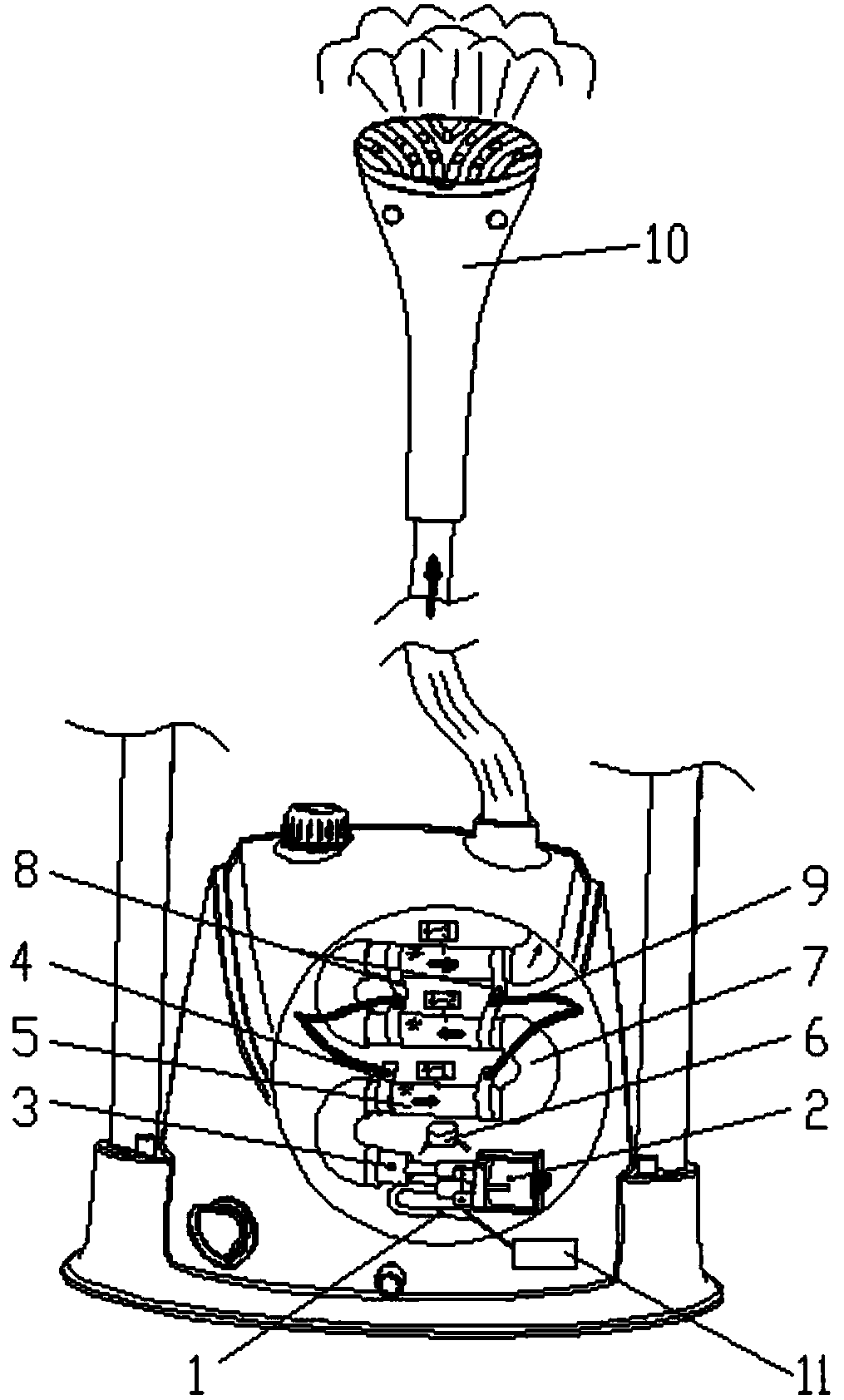

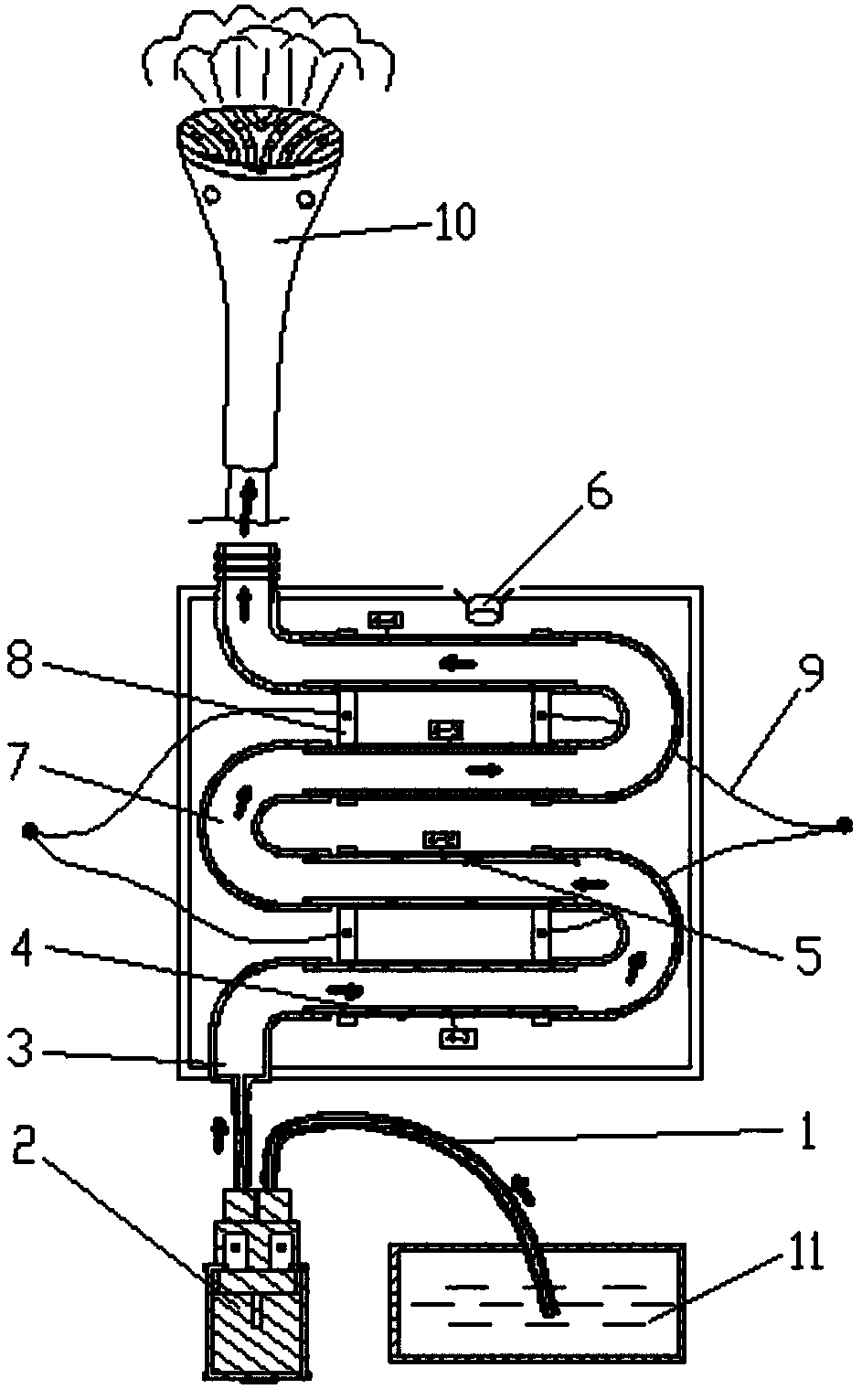

[0026] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following embodiments are combined with figure 1 Attached figure 2 A garment ironing machine with horizontal glass heating tube heating provided by the present invention is described in detail.

[0027] figure 1 It is a schematic structural view of an embodiment of a garment ironing machine with horizontal glass heating tube heating according to the present invention; figure 2 It is a cross-sectional view of an embodiment of a garment ironing machine with horizontal glass heating tube heating according to the present invention, such as Figure 1 to Figure 2 As shown, this embodiment provides a horizontal glass heating tube heating garment ironing machine, the horizontal glass heating tube heating garment ironing machine includes: suction pipe 1, electromagnetic pump 2, conversion joint 3, special heating Coating 4, glass heating tube 5, thermost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com