Method and apparatus for heating gas valve, in particular fuel injector, and a motor vehicle having method

A technology of fuel injectors and gas valves, which is applied in the direction of fuel injection devices, fuel injection control, mechanical equipment, etc., and can solve problems such as hazards, injectors not working properly, cold start, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

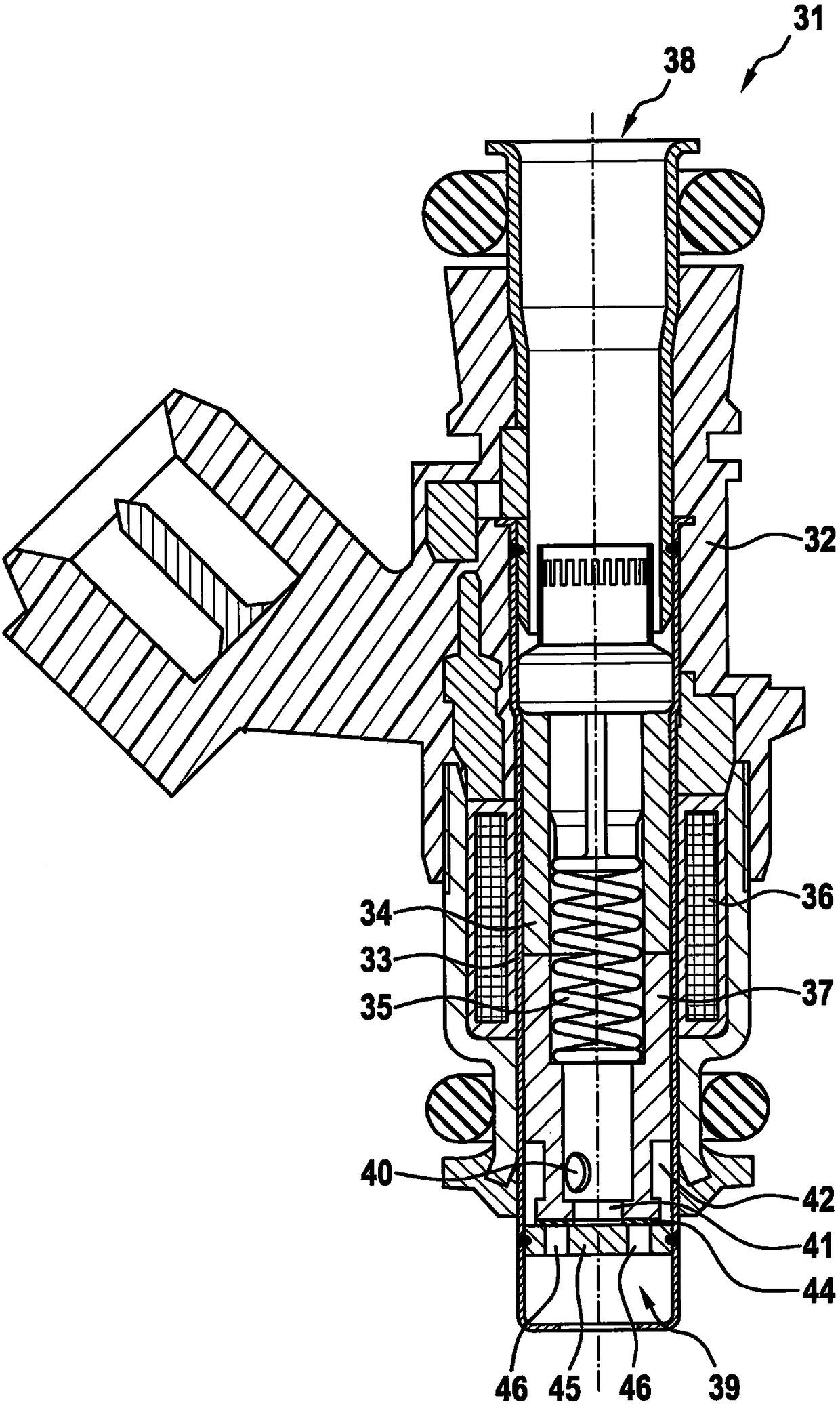

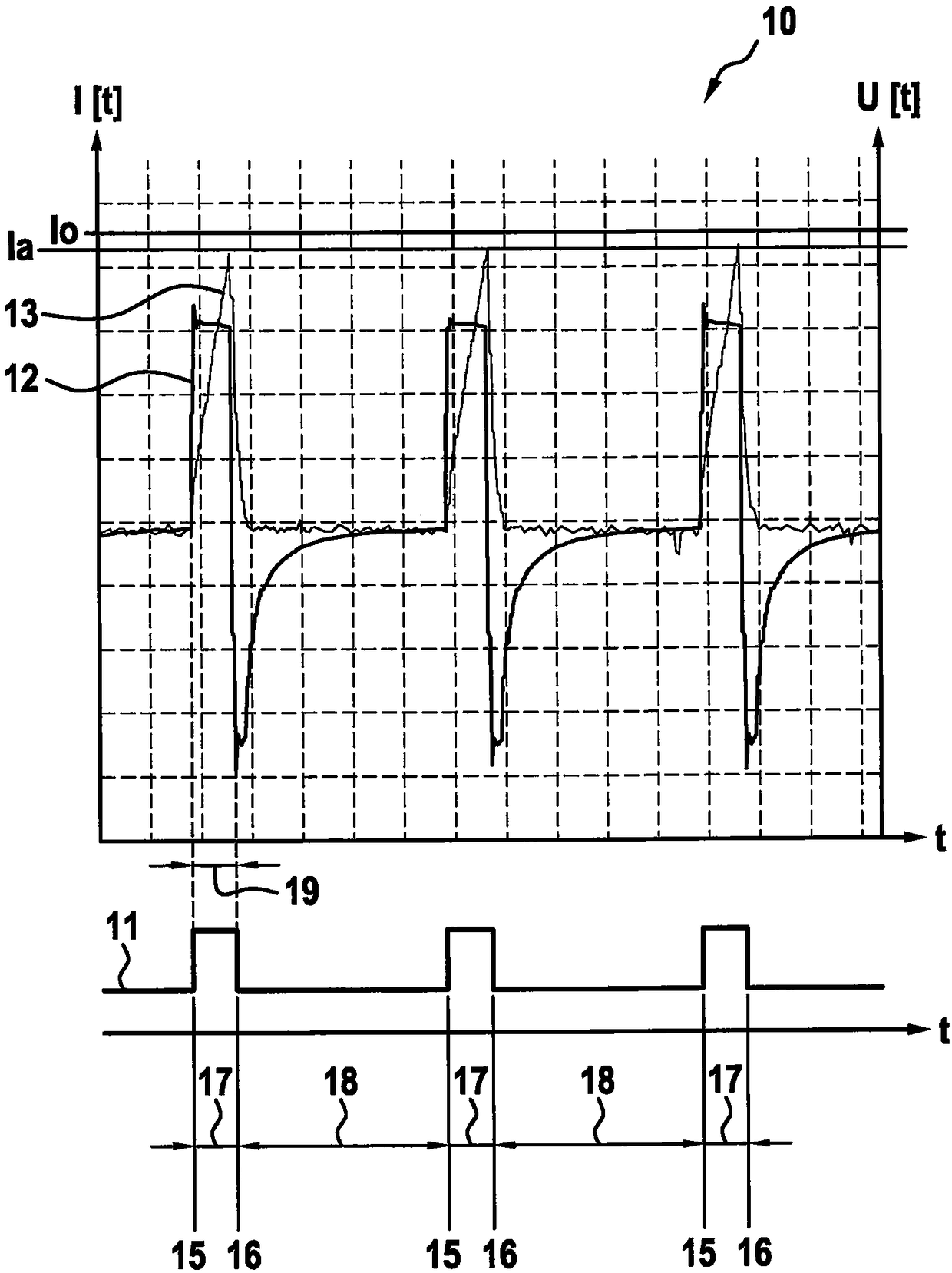

[0027] In the present application, the method according to the invention for heating a gas valve 31 with a magnetic coil 36 by generating swirl currents is described in terms of a gas valve 31 configured as a fuel injector 31 for injecting a gaseous fuel, such as CNG (compressed natural gas) Method and device according to the invention. However, the gas valve 31 can also be, for example, a gas valve 31 with a magnetic coil 36 for metering LNG (liquefied natural gas), wherein metal-to-metal seals, for example, can also bond due to the low temperature and can be achieved by this method and this The device is heated. In addition, the gas valve 31 with magnetic coil 36 is also, for example, an electrically regulated pressure regulator or an electric shut-off valve (shut off valve), or other gas valve 31 with magnetic coil 36 , wherein, due to low temperatures, Bonding of metal-elastomer seals or bonding of other seals, such as metal-to-metal seals, occurs.

[0028] figure 1 A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com