Measurement method for separation quantity of steel tube concrete

A technology for steel pipe concrete volume measurement, which is applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., which can solve the problems of high difficulty and low precision in void volume measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, and not to limit the present invention.

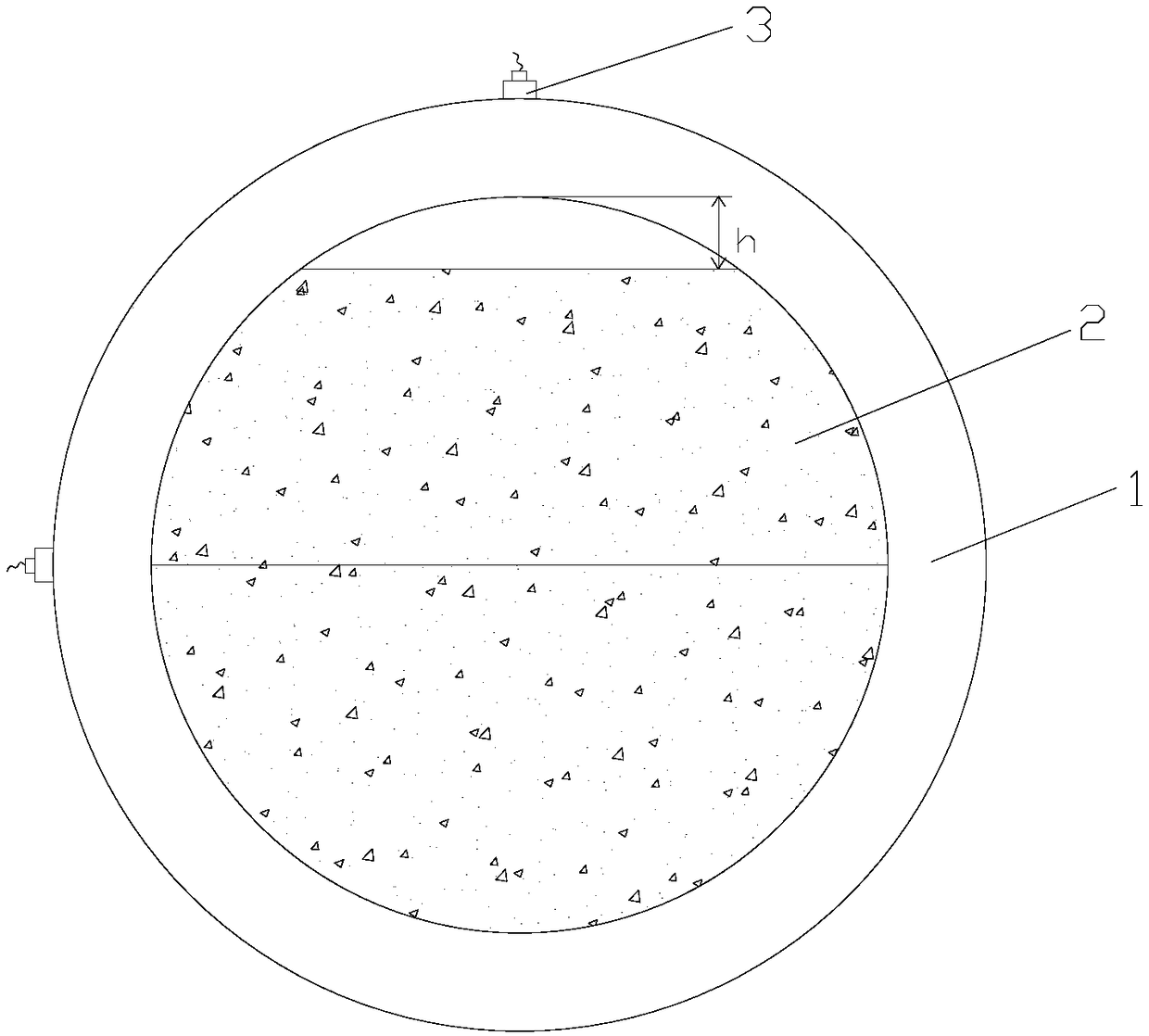

[0027] The present invention provides a method for measuring the void amount of steel tube concrete, wherein the steel tube concrete includes a steel tube 1 and concrete 2 filled in the steel tube 1, wherein the method for measuring the void amount of the steel tube concrete includes:

[0028] Step 1: Set acceleration sensors 3 on the dense position and vacant position on the outer peripheral wall of the steel pipe 1 respectively;

[0029] Step 2: Knock the steel pipe 1 near each of the acceleration sensors 3 to generate oscillating stress waves that reciprocate in the diameter direction in the steel pipe concrete, and measure the compactness by the corresponding acceleration s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com