Gearbox gear shift mechanism force measuring device

A technology of shifting mechanism and force measuring device, which is applied in the testing of machine gear/transmission mechanism, measuring device, and testing of machine/structural components, etc. First-class problems, to achieve the effect of convenient application, accurate measurement, and stable force measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

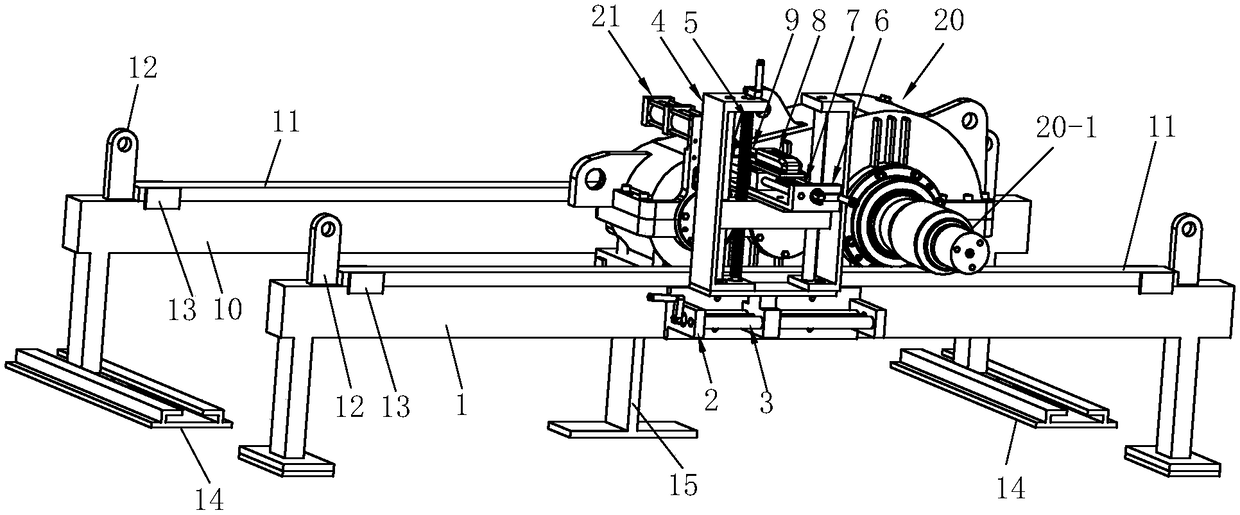

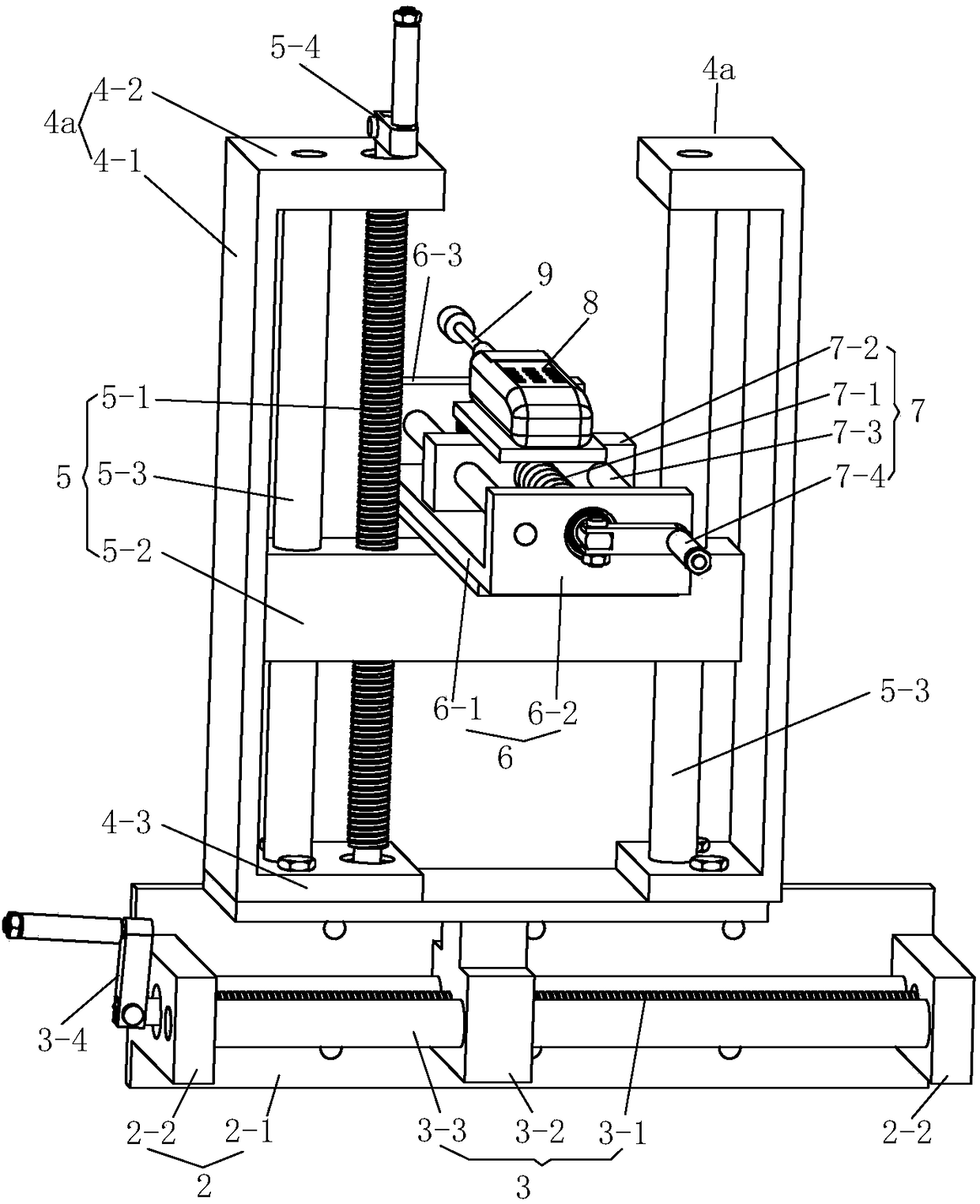

[0019] See Figure 1 to Figure 3 , this embodiment includes two front and rear parallel fixed chassis 1 and mobile chassis 10 arranged on the table top (not shown in the figure), each of the fixed chassis 1 and the mobile chassis 10 has two supporting legs, and a pair of Fore and aft to the guide rail 14, two supporting legs of the movable underframe 10 are respectively movable with the two guide rails 14, and the movable underframe 10 can move on the two guide rails 14, so that the spacing between the fixed underframe 1 and the movable underframe 10 can be adjusted. Since the two ends of the output shaft 20-1 of the gear box 20 are placed on the fixed chassis 1 and the movable chassis 10 respectively, in order to protect the two ends of the output shaft 20-1 of the gear box 20 from being damaged, the fixed chassis 1 and the mobile chassis 10 are not damaged. Rubber pads 11 are provided on the upper surface of the mobile chassis 10 , so that both ends of the output shaft 20 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com