Double-disc type lubricating oil traction force testing machine

A double disc type, dragging force technology, applied in the field of measuring instruments in the field of measurement and control technology, can solve the problems of inability to achieve simultaneous axial and radial loading, accurate testing of influences, and difficulty in changing discs, and achieves compact structure and high loading. The effect of large range and improved test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

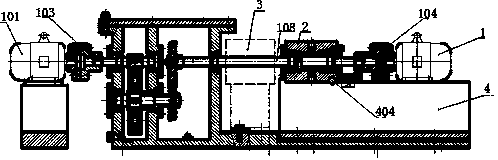

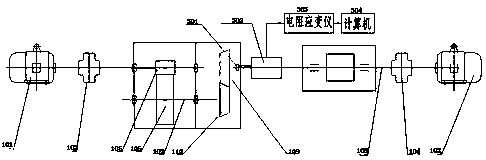

[0031] As shown in the figure, a double-disc lubricating oil drag force testing machine is composed of a motion simulation mechanism 1, a hydraulic loading mechanism 2, a force measuring mechanism 3 and a test disk quick replacement mechanism 4,

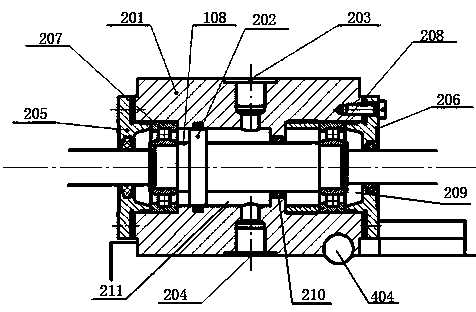

[0032] Described hydraulic loading mechanism 2 is provided with box body 201, is provided with a cavity 209 in the box body 201, is provided with boss 210 on the inner wall of box body 201, is provided with the upper disc shaft 108 of shaft shoulder 202 to pass through the cavity. Cavity 209, and form a hydraulic cavity 211 between the boss 210 and the inner wall of the box body 201, the two ends of the box body 201 are respectively provided with bearing end cover I 205 and bearing end cover II 206, the upper end of the box body 201 is provided with an oil inlet 203, and the lower end An oil drain port 204 is provided, and cylindrical roller bearings I 207 and cylindrical roller bearings II 208 are provided at both ends of the box bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com