Flexible jack

A jack and flexible technology, applied in the direction of lifting devices, etc., can solve the problems of load loss, small output, inaccurate output measurement, etc., and achieve the effects of improving technology and test quality, clear force transmission path, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

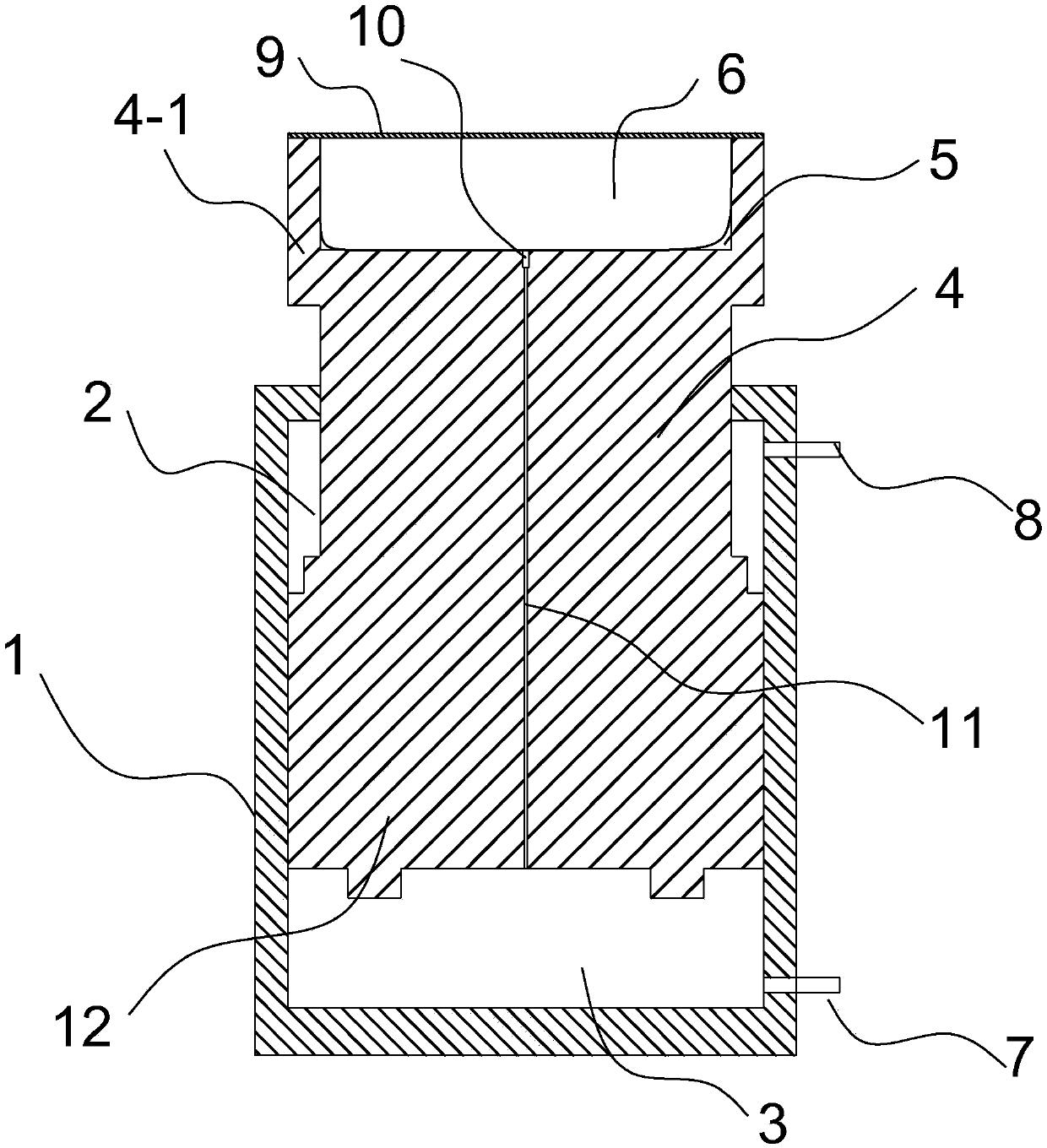

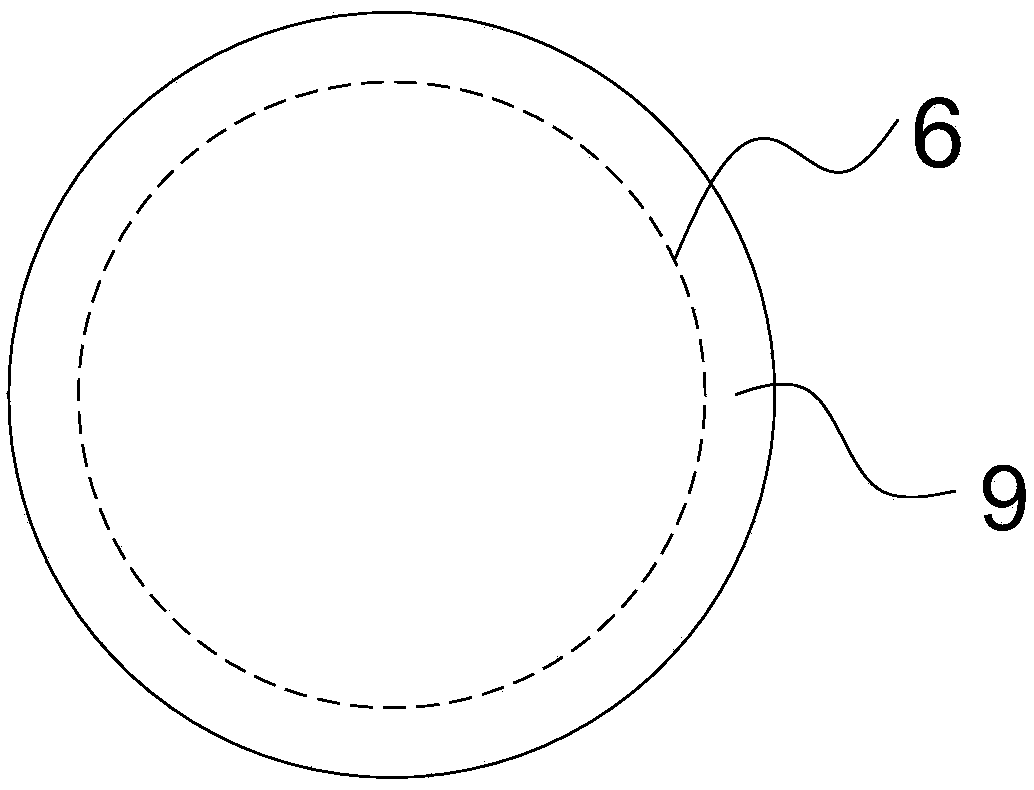

[0027] A kind of flexible jack that embodiment one provides, as Figure 1 to Figure 3Shown comprises cylinder body 1, piston rod 4 and the piston 12 that places in cylinder body 1, and its cylinder body 1 is circular, and piston 12 is circular, is provided with piston chamber in cylinder body 1, and piston chamber is covered by piston 12 The upper oil cylinder 2 and the lower oil cylinder 3 are separated, and the lower part of the lower oil cylinder 3 is provided with a pressurizing oil nozzle 7, and the upper part of the upper oil cylinder 2 is provided with a depressurizing oil nozzle 8, and the pressurizing oil nozzle 7 and the depressurizing oil nozzle 8 extend out of the cylinder body 1. It is also used to connect with external hydraulic pipelines. The piston rod 4 is made of high-strength steel, one end is connected to the piston 12, and the end away from the piston 12 protrudes from the piston chamber, and the end is provided with an ejection end 4- with the same sectio...

Embodiment 2

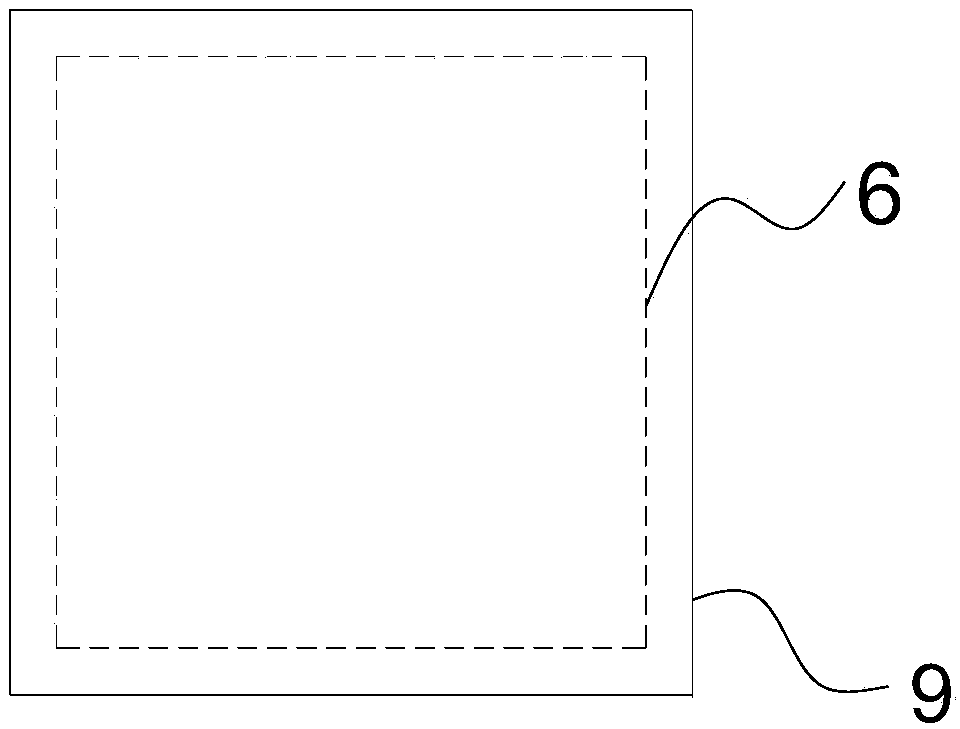

[0032] A kind of flexible jack that embodiment 2 provides, the structure of its cylinder 1, piston rod 4 and piston is the same as embodiment 1, and its difference is that no flexible chamber is provided at the pushing end of the piston rod, and a flexible cavity is provided at the bottom of cylinder 1. The lower bump 1-1 with the same width as the piston 12 has an upward flexible cavity 5 on the bottom surface of the lower bump 1-1, and a flexible pressure-bearing bag matching the shape of the cavity is arranged in the flexible cavity 5 6. A flexible pressure-bearing pad 9 is provided at the mouth of the flexible cavity 5 where the flexible pressure-bearing bladder 6 is located. The mouth of the cavity is fixedly connected; the flexible pressure-bearing bag 6 communicates with the lower oil cylinder 3 through the oil hole 11 arranged on the central axis of the bottom plate of the cylinder body 1, and the non-corrosive hydraulic oil is filled into the flexible pressure-bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com