Square circle-sleeving hollow sandwich steel pipe concrete column and steel beam connecting joint and construction method

A technology for steel pipe concrete columns and connecting nodes, which is applied in the direction of construction and building construction, to achieve the effects of clear force transmission path, reliable connection, and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

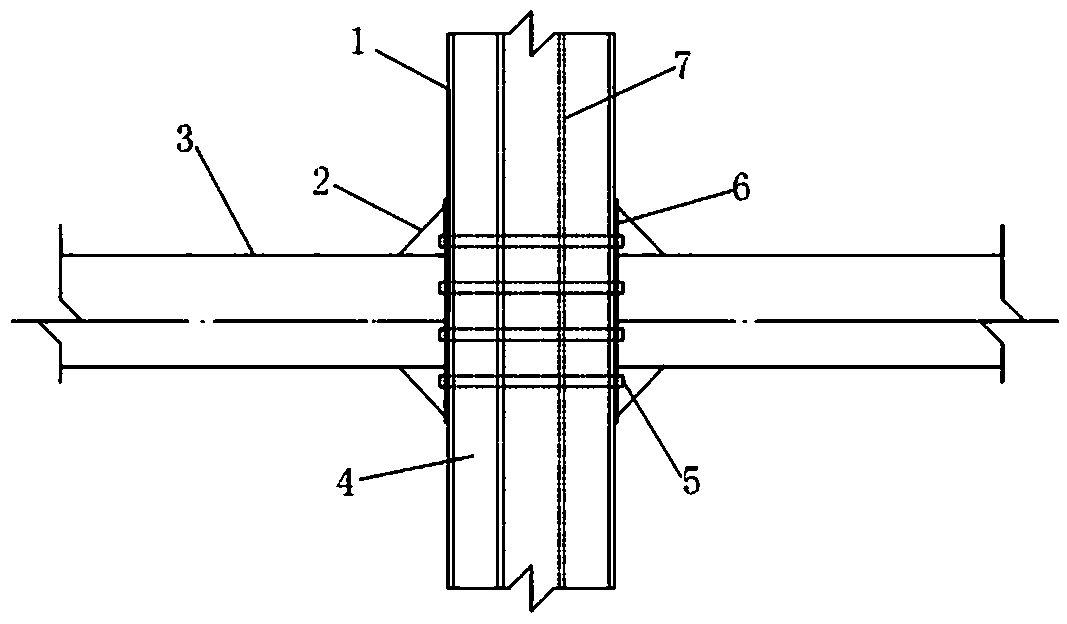

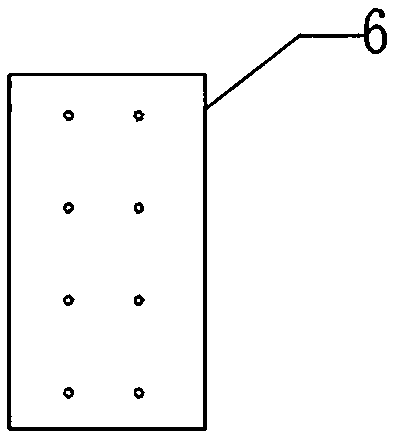

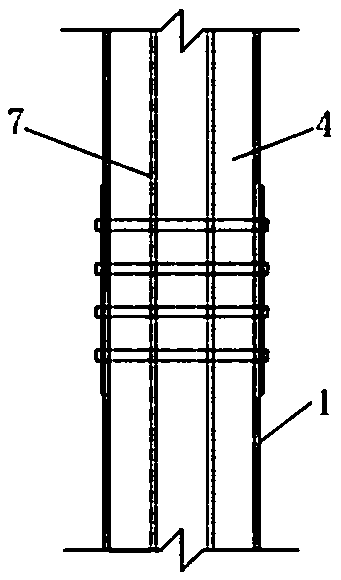

[0019] Such as Figure 1~5 As shown in the figure, a connection node between a square-circle hollow interlayer concrete-filled steel tube column and a steel beam includes an outer steel tube 1, a rib plate 2, a steel beam 3, concrete 4, a high-strength bolt 5, an end plate 6 and an inner circular steel tube 7; The end of the steel beam 3 is vertically fixed on the end plate 6, and the rib plate 2 is welded along the direction of the beam web at the upper and lower joints of the steel beam 3 and the end plate 6; the end plate 6 with the steel beam 3 fixed on the outside The outer sides of the square steel pipe 1; the high-strength bolts 5 pass through the end plate 6, the outer steel pipe 1, the concrete 4 and the inner round steel pipe 7 in turn, and the steel beam 3 is vertically installed on the outer steel pipe 1; the steel beam 3 is an I-shaped Steel beams, H-shaped steel beams or box-shaped steel beams; the steel beam 3 and the end plate 6 are connected by welding.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com