Beam through mortise and tenon type node structure of assembly type steel structure and assembly method of node structure

A technology for steel structure beams and node structures, which is applied in building structures and buildings, can solve the problems of high welding quality requirements, poor seismic performance of nodes, and large size of reinforcement rings, so as to achieve less welding workload, improve seismic performance, Connection for reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

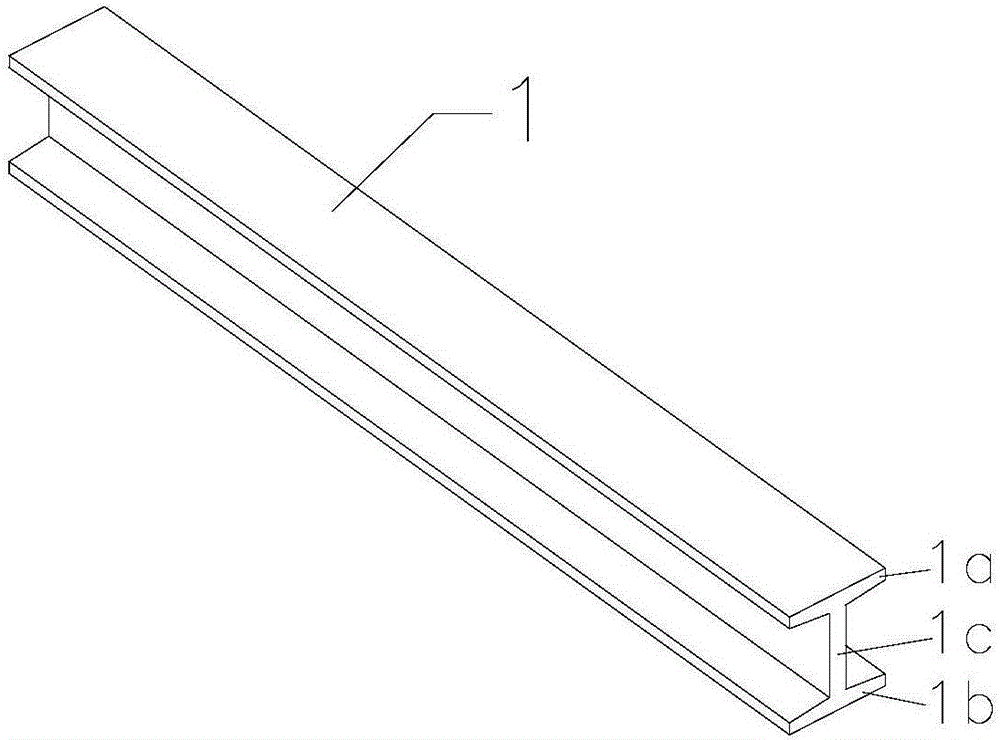

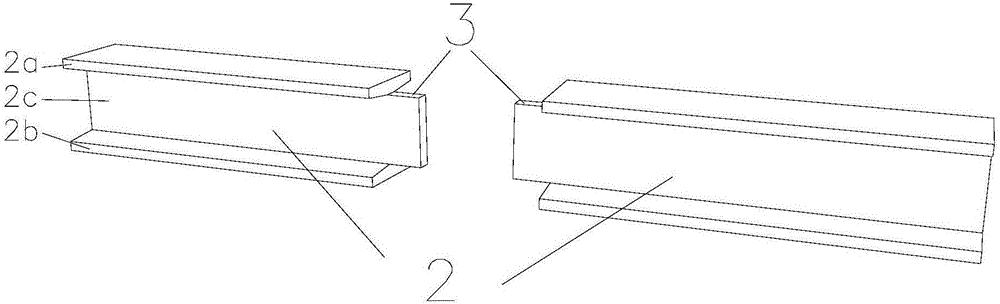

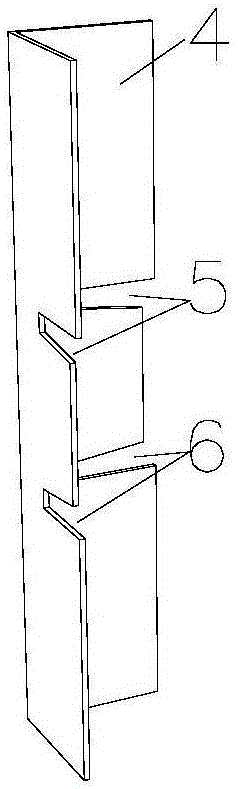

[0040] Such as Figure 1-Figure 13 As shown, the beam-column mortise and tenon joint structure of the assembled steel structure of the present invention mainly includes: through mother beam 1, mother beam upper flange 1a, mother beam lower flange 1b, mother beam web 1c, cut-off sub-beam 2, and sub-beam upper flange 2a, sub-beam lower flange 2b, sub-beam web 2c, sub-beam connection key 3, 1 / 4 mortise and tenon steel pipe column 4, upper mortise and tenon groove 5, lower mortise and tenon groove 6, splicing partition 7, common Steel beam 8, ordinary steel pipe column 9, etc., the specific structure is as follows:

[0041] Such as figure 1 As shown, the through mother beam 1 of the present invention is composed of the mother beam upper flange 1a, the mother beam lower flange 1b and the mother beam web 1c, and the mother beam upper flange 1a and the mother beam lower flange 1b are respectively located above and below the mother beam web 1c sides.

[0042] Such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com