A method for measuring internal flow resistance in wind tunnel tests

A measurement method and wind tunnel test technology, applied in the field of wind tunnel test, can solve the problems of pressure measurement error, limited number of pressure measurement rake probes, and inability to arrange pressure measurement points, etc., and achieve high data collection density and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

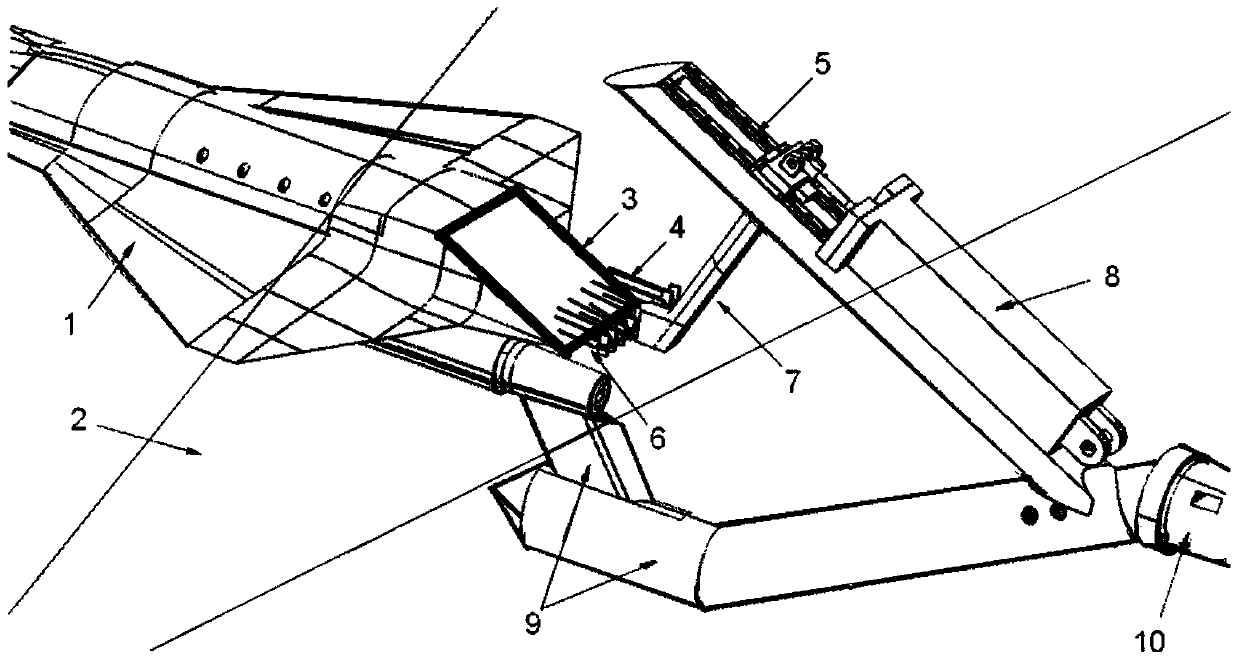

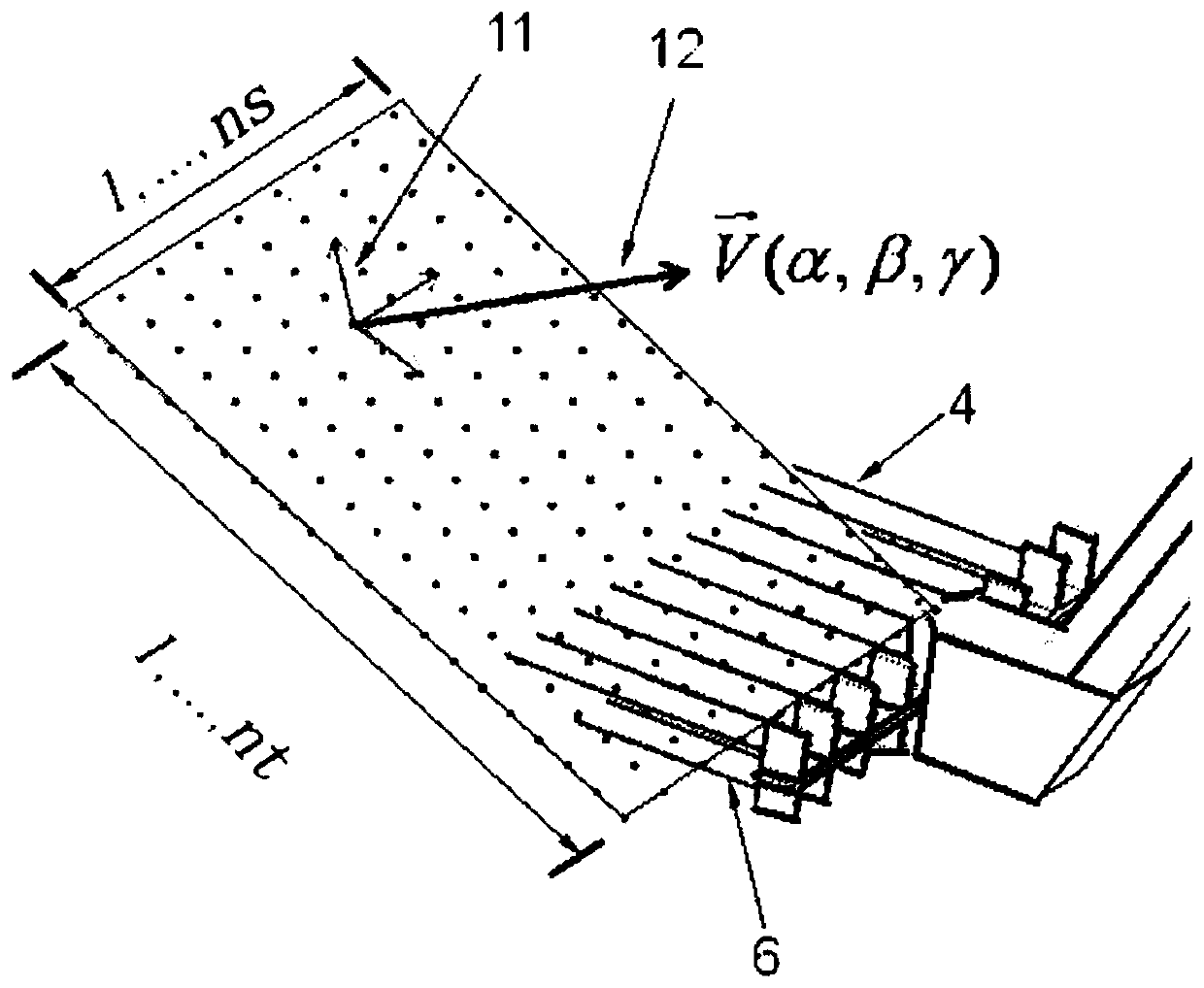

[0072] combine figure 1 and figure 2 , the following examples are given to further illustrate the technical implementation of the present invention.

[0073] The ventilation model 1 for typical internal flow resistance measurement is installed in the wind tunnel, the ventilation model 1 is installed on the model support base 9, and the model support base 9 is connected with the scimitar connector 10 of the wind tunnel. The trajectory control slide rail 5 is fixedly installed on the model support base 9 , and the pressure measuring rake support arm 7 can move in the trajectory control slide rail 5 through the drive of the electric cylinder 8 . The free end of the pressure measuring rake support arm 7 is a pressure measuring rake, on which the pressure measuring rake total pressure measuring probe array 4 and the pressure measuring rake static pressure measuring probe array 6 are installed.

[0074] (1) The side wall lighting area 2 of the wind tunnel is lit with a laser, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com