Device and method for rapidly determining design eye position of hoisting head-up display

A head-up display and eye position technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of high test site requirements, unstable error accuracy, and low positioning accuracy, and achieve low installation environment requirements, The effect of avoiding error fluctuation and accurate positioning method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

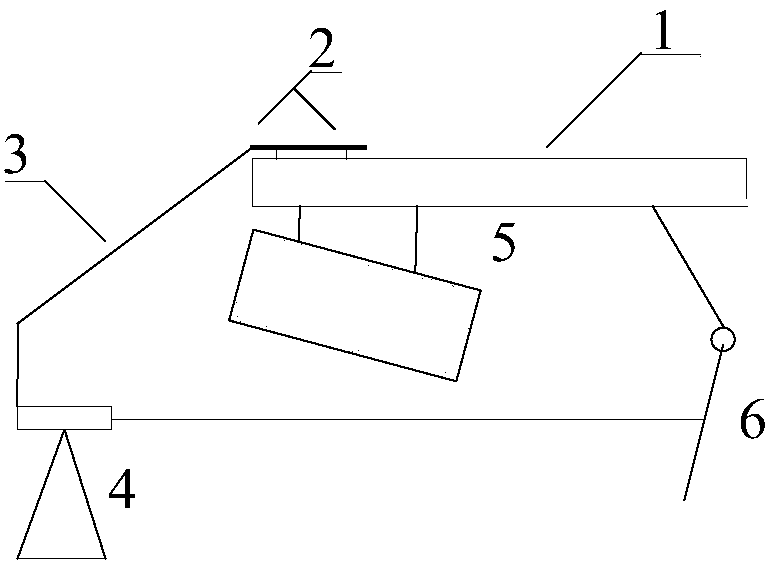

[0026] The invention utilizes the principle that the relative spatial position relationship between the HUD design eye position and the center point of the mounting bracket is fixed, and determines the spatial position of the reference eye position through a bent metal plate mounted on the mounting bracket.

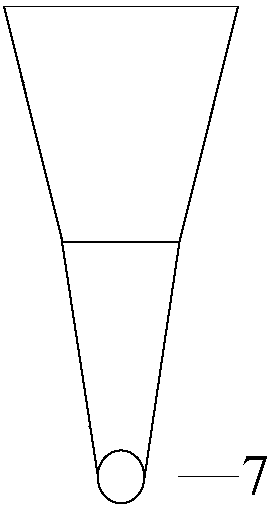

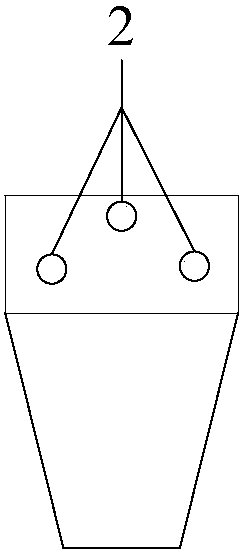

[0027] Firstly, according to the relative distance between the design eye position of the hoisting HUD and the center point of the hoisting HUD mounting bracket in the direction perpendicular to the plane of the mounting bracket, a rigid bent metal plate is designed and processed. The metal plate is divided into a fixed section, a transition There are three sections of connection section and observation section, the fixed section and the observation sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com