Gas-liquid two-phase self-adaption constant flow distributor

A self-adapting, distributor technology, applied in liquid degassing, separation methods, mixer accessories, etc., can solve problems such as the inability to quickly adjust the flow rate, pre-enhanced mixing or rectification distribution methods, narrow application scope, engineering application limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

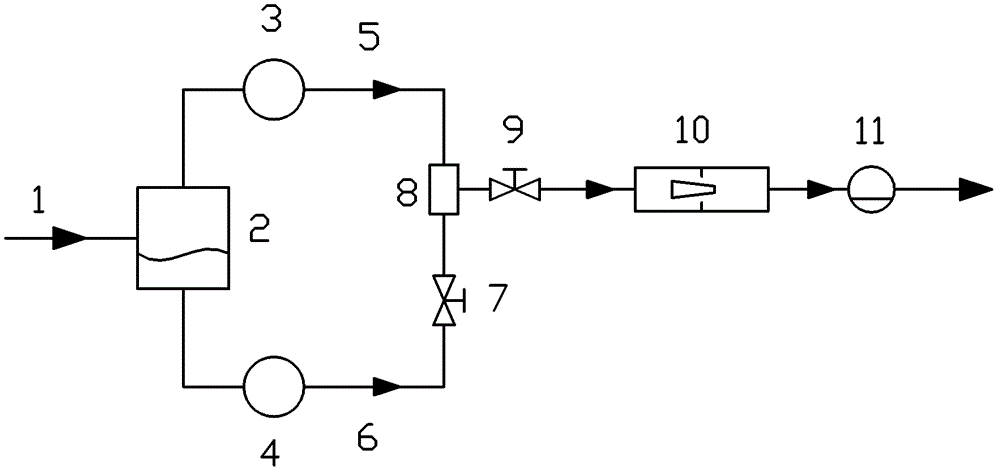

[0035] Such as figure 1 As shown, the self-adaptive constant flow distributor of gas-liquid two-phase fluid of the present invention comprises an incoming main pipeline 1, a gas-liquid separator 2 connected with the incoming main pipeline 1, an upper end of the gas-liquid separator 2 and a gas header 3 are connected, the lower end is connected with the liquid header 4, the gas header 3 and the liquid header 4 are respectively connected with the mixer 8 through the gas branch 5 and the liquid branch 6, and the liquid header 4 and the mixer 8 A dryness regulating valve 7 is provided on the liquid branch 6 between them, and a flow regulating cut-off valve 9 , an adaptive constant flow valve 10 and a dryness flowmeter 11 are sequentially installed on the distribution branch after the gas-liquid mixer 8 .

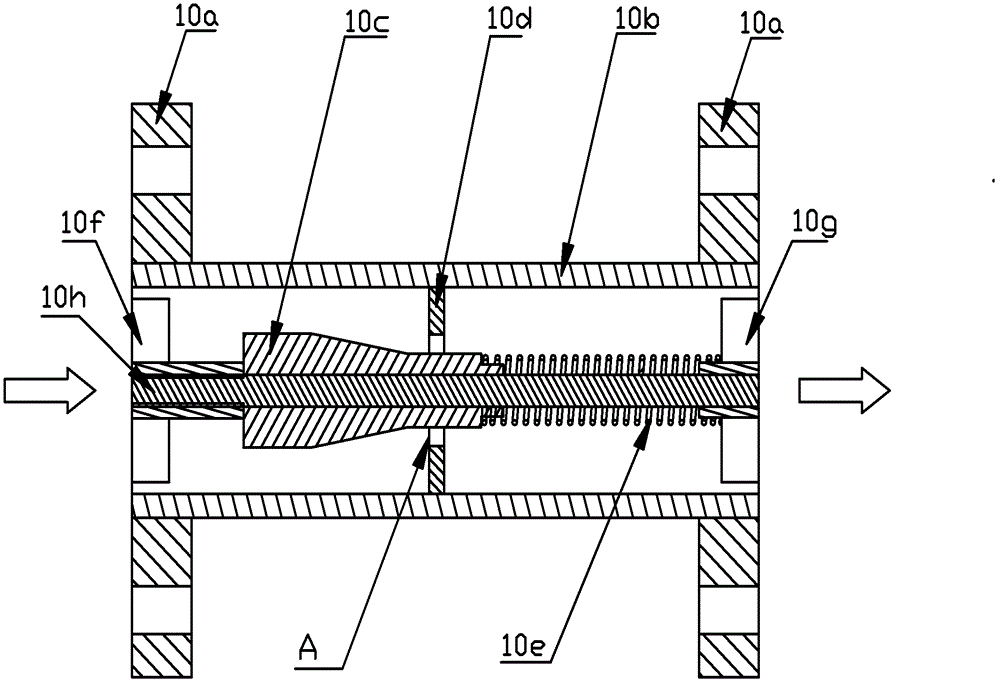

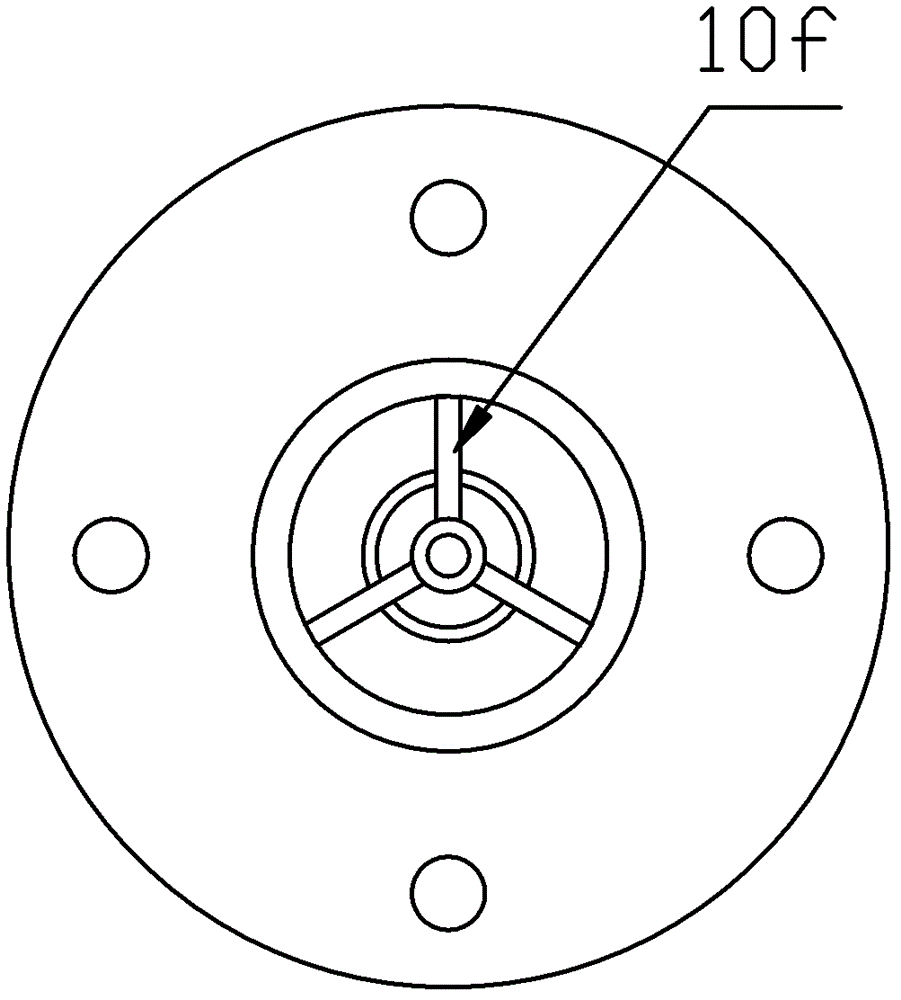

[0036] Such as figure 2 with image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com