LED display screen and preparation method thereof

A technology of LED display and LED lamp beads, which is applied in the direction of instruments, identification devices, etc., can solve the problems of heavy ink, low efficiency, short circuit of LED display, etc., and achieve the effect of strong sense of unity, high efficiency and improved contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a kind of preparation method of LED display screen, comprises the following steps:

[0031] preset a printed circuit board;

[0032] Fixing a plurality of LED lamp beads on the printed circuit board, the plurality of LED lamp beads are arranged in an array and there is a gap between adjacent LED lamp beads;

[0033] applying an adhesive into the gap;

[0034] Put the printed circuit board after the above treatment into the flocking equipment for flocking. After the flocking is completed, after the glue is cured, the excess fluff is cleaned to obtain an LED with only fluff stuck in the gap between adjacent lamp beads. display screen.

[0035] As can be seen from the foregoing description, the beneficial effects of the present invention are:

[0036] The preparation method of the LED display screen provided by the present invention uses flocking to replace the face mask. Since the manufacturing cost of the traditional small-pitch mas...

Embodiment 1

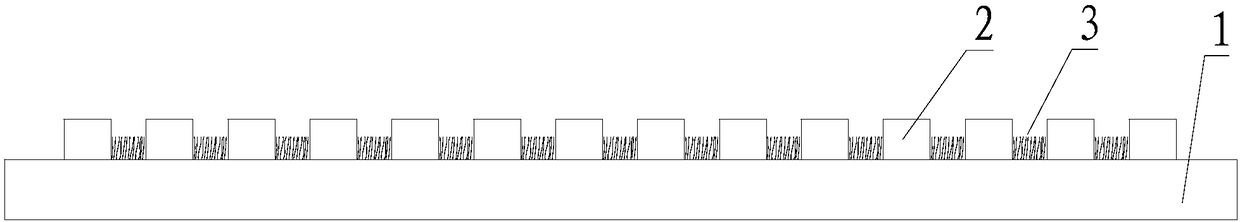

[0051] Please refer to figure 1 Shown, embodiment one of the present invention is:

[0052]An LED display screen, comprising a printed circuit board 1 and a plurality of LED lamp beads 2 arranged in an array fixed on the printed circuit board 1; there is a gap between adjacent LED lamp beads 2, and glued in the gap Knot fluff3.

[0053] The fluff 3 is nylon flame-retardant fluff of dark colors such as black, brown or navy blue.

[0054] The height of the fluff 3 is smaller than that of the LED lamp bead 2 .

Embodiment 2

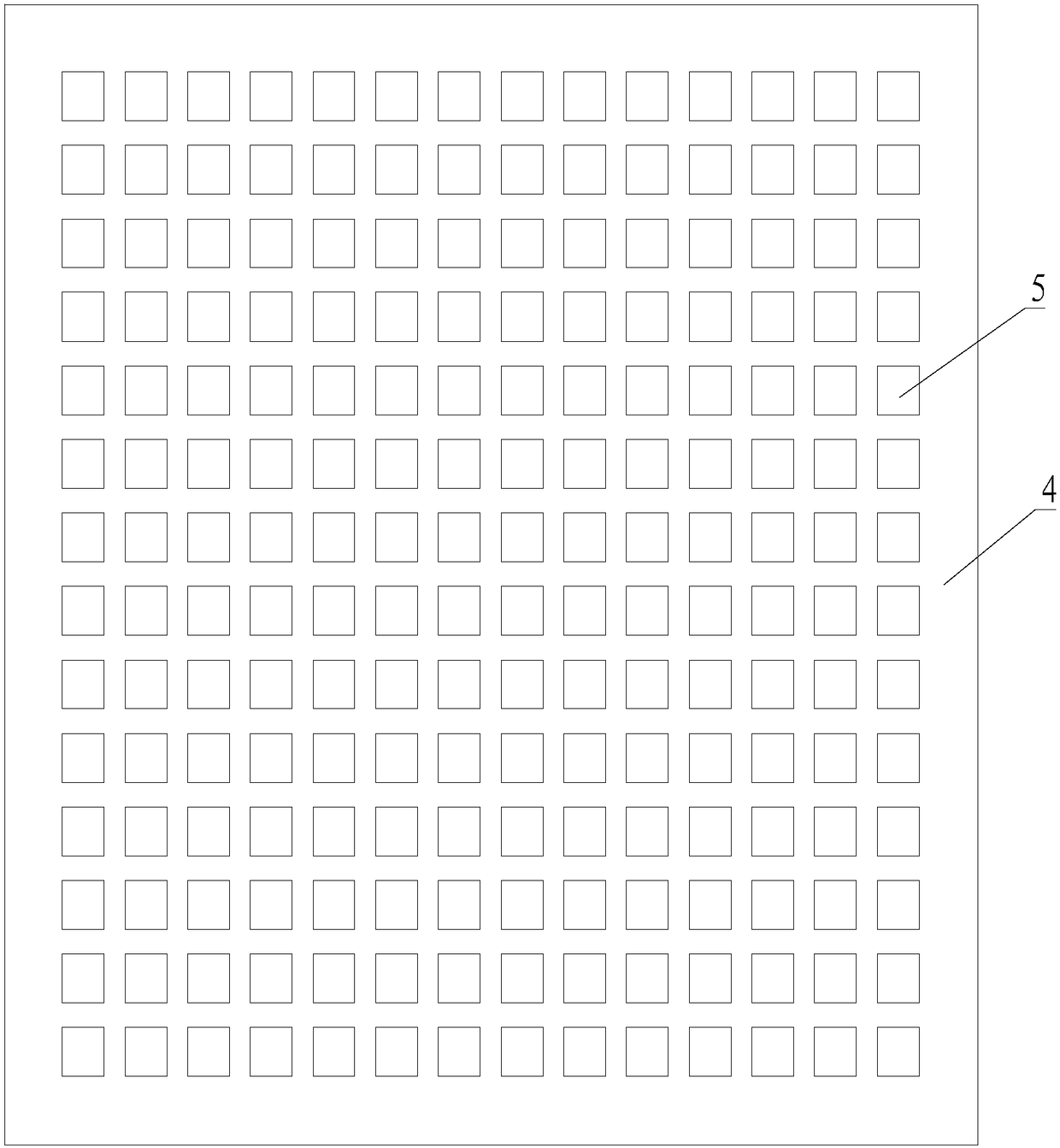

[0055] Please refer to figure 2 Shown, embodiment two of the present invention is:

[0056] A method for preparing an LED display, comprising the steps of:

[0057] Step 1: preset a printed circuit board;

[0058] Step 2: Fix a plurality of 1*1*1mm LED lamp beads on the printed circuit board, the plurality of LED lamp beads are arranged in an array and there is a gap between adjacent LED lamp beads; adjacent LED lamp beads The center distance between beads is 1.588mm;

[0059] Step 3: Take a planar grid-shaped jig 4, the thickness of the jig 4 is 0.4mm, and the material is 304 stainless steel; the jig 4 consists of hollow squares 5 of 1.2*1.2mm arranged in an array grid, the grid of the jig 4 corresponds to a plurality of LED lamp beads on the printed circuit board; the center-to-center distance of adjacent hollow squares 5 is 1.588mm; the number of hollow squares 5 on the jig 4 The same number as the number of lamp beads on the printed circuit board;

[0060] Step 4: Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com