Convenient-to-use welding device

A welding device, a convenient technology, applied in the parts of the connection device, the device for preventing contact with live contacts, the coupling device, etc., can solve the problems of poor plug stability, user electric shock, poor contact, etc., and achieve convenient power connection Effects of connection and prevention of electric shock accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

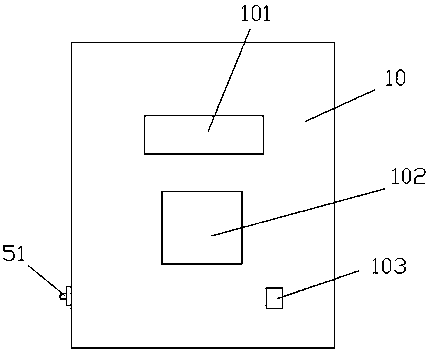

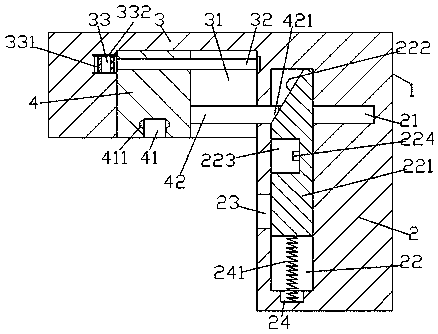

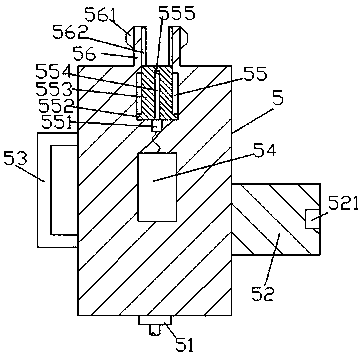

[0022] Such as Figure 1-Figure 6 As shown, a convenient welding device of the present invention includes a welding body 10 and a power connection device. The front end of the welding body 10 is respectively provided with a switch 103, a liquid crystal display 101, and a converter 102. The power connection The device includes a power connection box 1 and a power connection head 5 composed of a push-in part 3 and a power connection part 2. The push-in part 3 is fixedly arranged at the upper left side of the power connection part 2. The push-in part 3 A push-in sliding groove 31 is provided in the end surface of the bottom, and a first screw rod 32 extending left and right is arranged in the described push-in sliding groove 31, and the left side end of the first screw rod 32 is connected with the first motor 33 Connected, the right side end of the first screw rod 32 is rotationally connected with the right inner end of the push-in sliding groove 31, and the first screw rod 32 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com