Improved water cup

An improved water cup technology, which is applied to water boiling appliances, electrical components, coupling devices, etc., can solve the problems of cup body burning, exposed power transmission grooves, and power transmission terminals detached, and achieves simple and convenient operation, safe and stable power supply, Good power supply stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

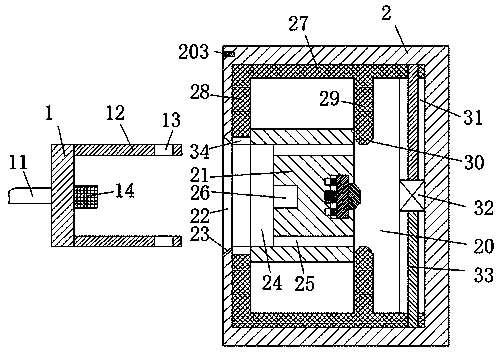

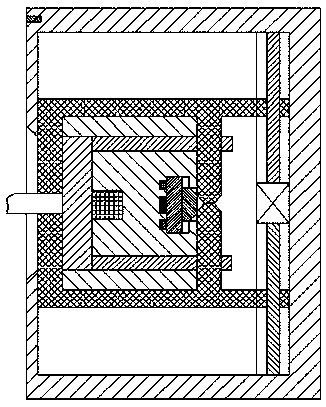

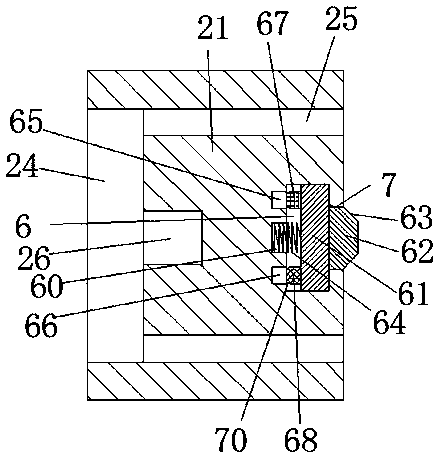

[0019] refer to Figure 1-4 The shown improved water cup includes a power transmission terminal connected to the cup body 100 through a wire 11 and a power transmission frame. The opening and closing is provided with a cup cover 103, and the power transmission terminal includes a push arm 1, and the front and rear ends of the right end surface of the push arm 1 are correspondingly provided with two insertion arms 12, and the right ends of the two insertion arms 12 are respectively A passage 13 is provided, a bumper 14 is provided at the center of the right end face of the push arm 1, the power transmission frame includes an outer frame 2, a hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com