Method and device for manipulating an internal conductor

一种内导体、设备的技术,应用在拆卸/铠装电缆的设备、连接/端接电缆的设备、电气元件等方向,能够解决分离方式未限定等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

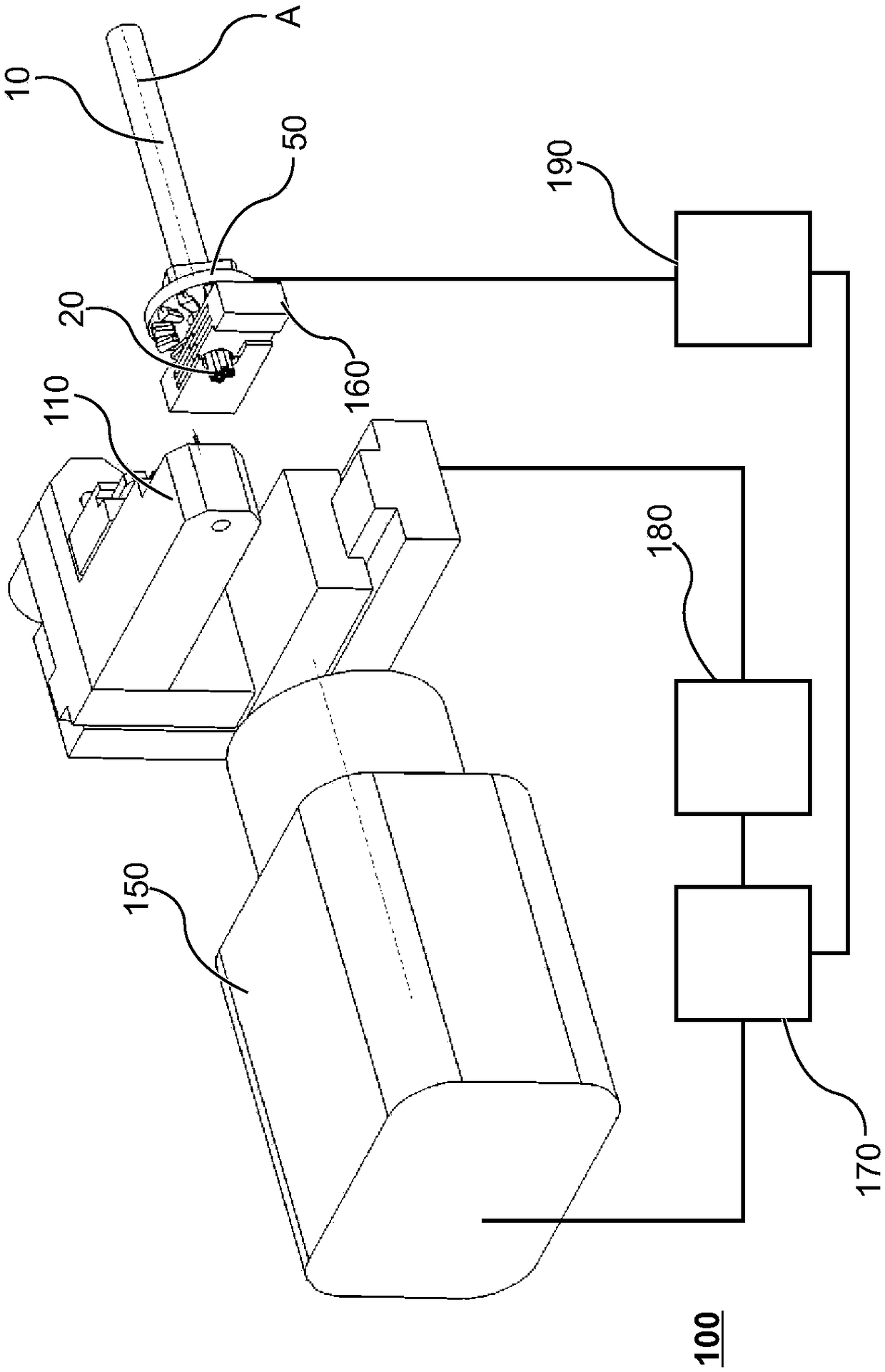

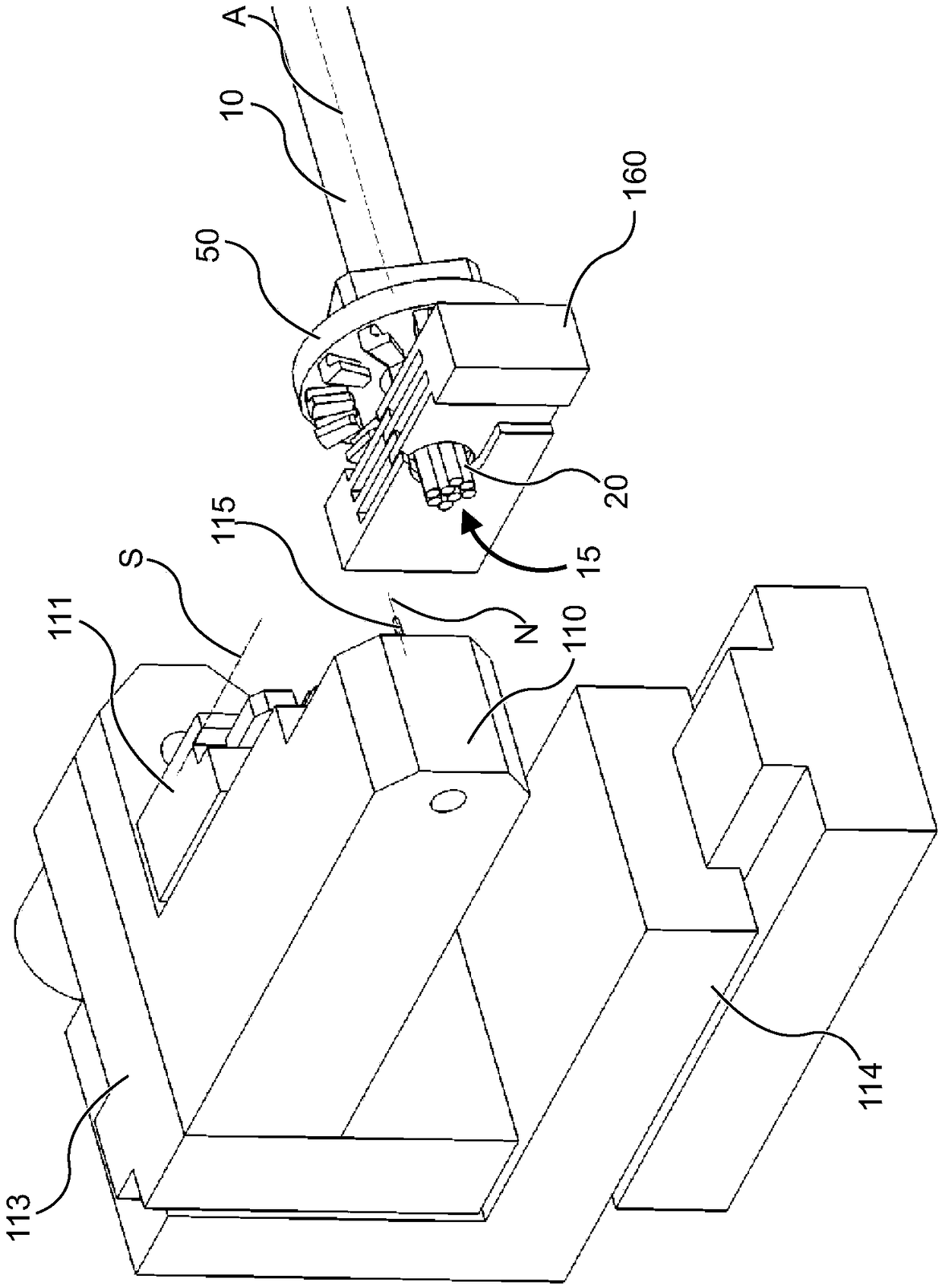

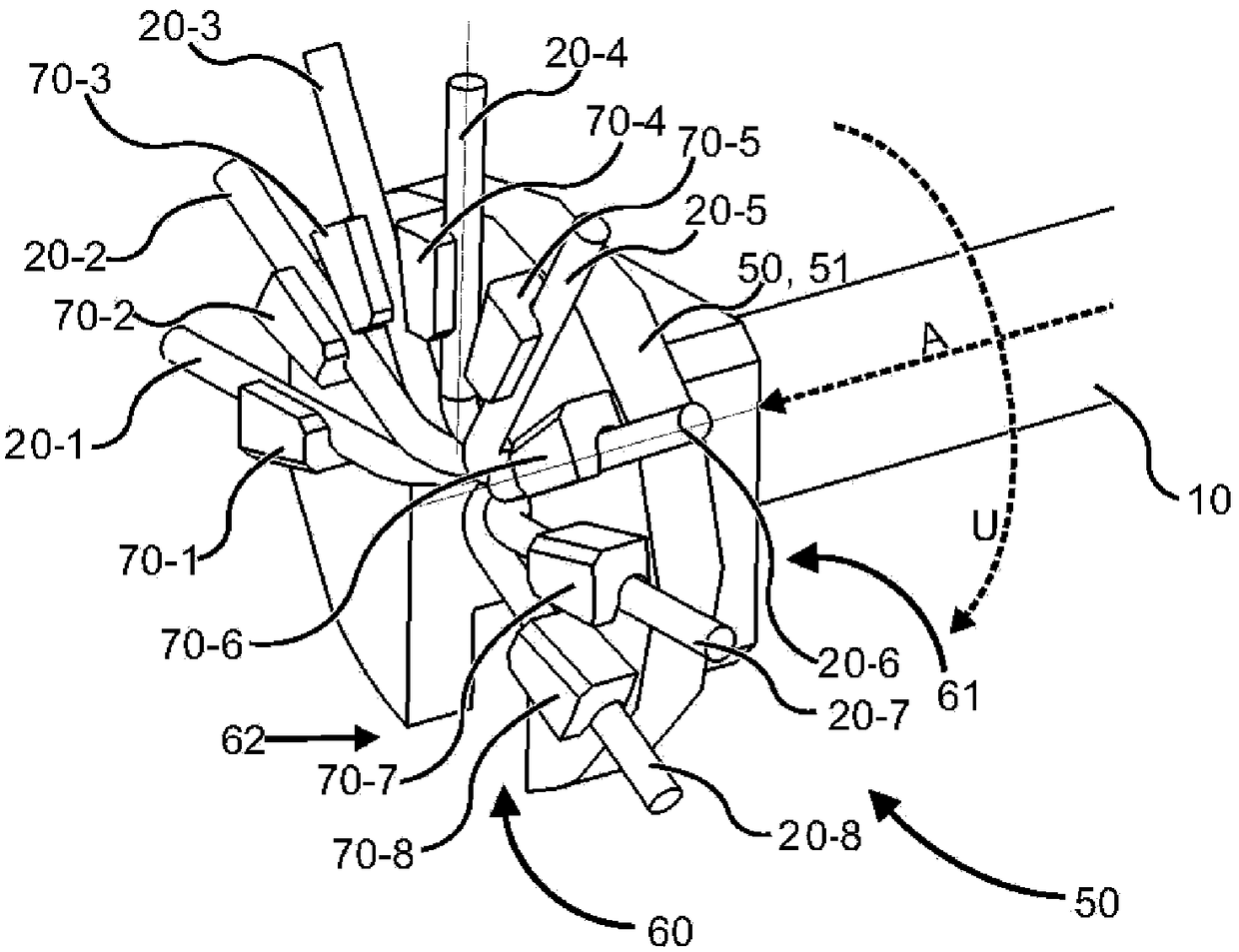

[0045] figure 1 A schematic perspective view of a device 100 for manipulating an inner conductor 20 of a plurality of inner conductors 20 at a stripped end of a sheathed cable 10 according to an embodiment of the invention is shown. The inner conductors are marked with the reference numeral 20 as long as the individual inner conductors of the inner conductor bundle are not distinguished in the description. The sheathed cable 10 extends substantially rectilinearly along a cable axis defining an axial direction A. As shown in FIG. At the stripped end of the sheathed cable 10, each inner conductor 20 is figure 1 likewise extend linearly along the respective inner conductor axis and parallel to the cable axis, figure 1 The state before the progress of the operation of the inner conductor 20 is shown.

[0046] The sheathed cable has an end portion where the outer insulator, sheath of the sheathed cable 10 is removed and the inner conductor 20 is exposed. Each inner conductor 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com