A kind of pressing method of mixed pressing plate

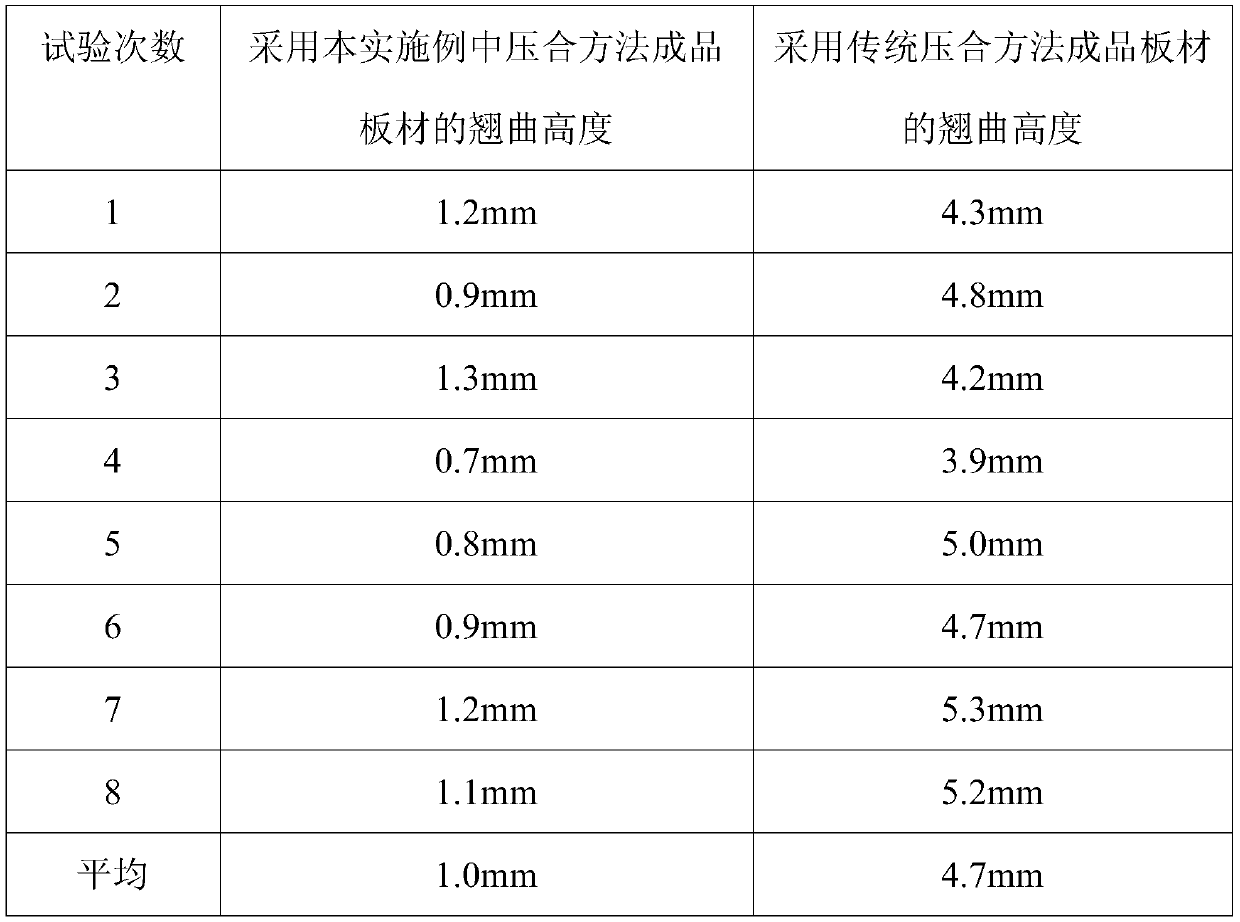

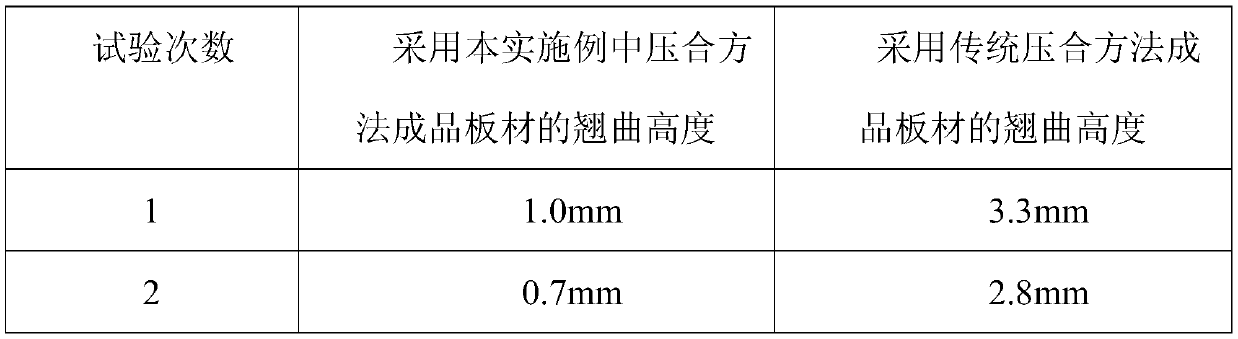

A hybrid, core board technology, used in multilayer circuit manufacturing, printed circuits, electrical components, etc., can solve problems such as warpage of finished boards, reduce expansion and shrinkage, stabilize expansion and shrinkage, and improve warpage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

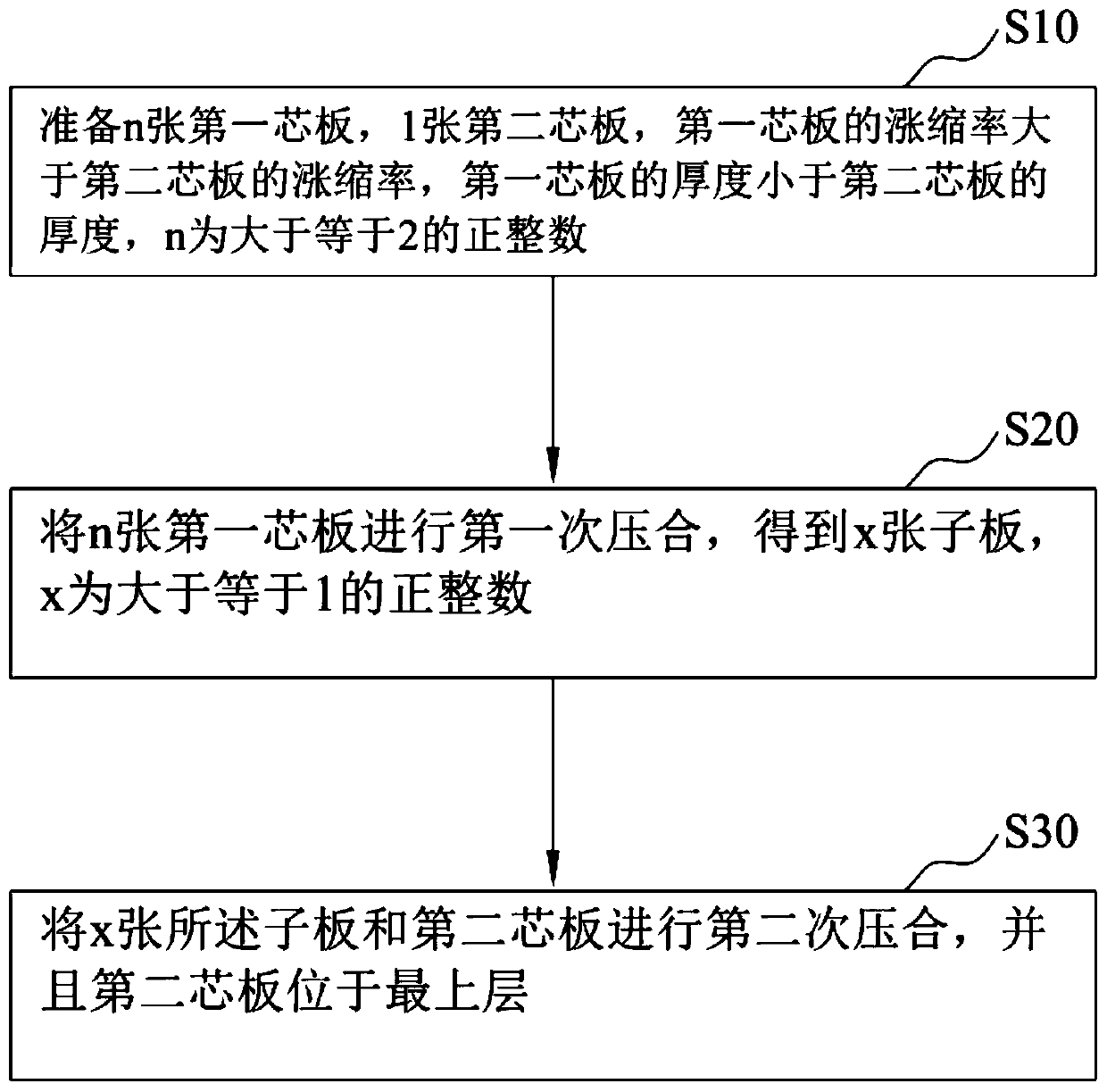

[0025] This embodiment provides a pressing method for mixed pressing boards, such as figure 1 shown, including

[0026] S10: Prepare n first core boards and 1 second core board, the expansion and shrinkage ratio of the first core board is greater than that of the second core board, the thickness of the first core board is smaller than the thickness of the second core board, n is a positive integer greater than or equal to 2.

[0027] It should be noted that in this embodiment, the first core board uses FR4 board, and the second core board uses high-frequency board. By setting the high-frequency board with excellent performance on the outer layer and the ordinary FR4 board on the middle layer, the electronic The electrical and thermal requirements of components can also reduce the preparation cost ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com