Method of and tool for fine-cutting pieces with small edge radius and strongly reduced depth in a single step arrangement

A precision blanking, corner radius technology, applied in the direction of manufacturing tools, metal processing, forming knives, etc., to achieve the effect of accurate functional length, less use, and reduced pressure load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

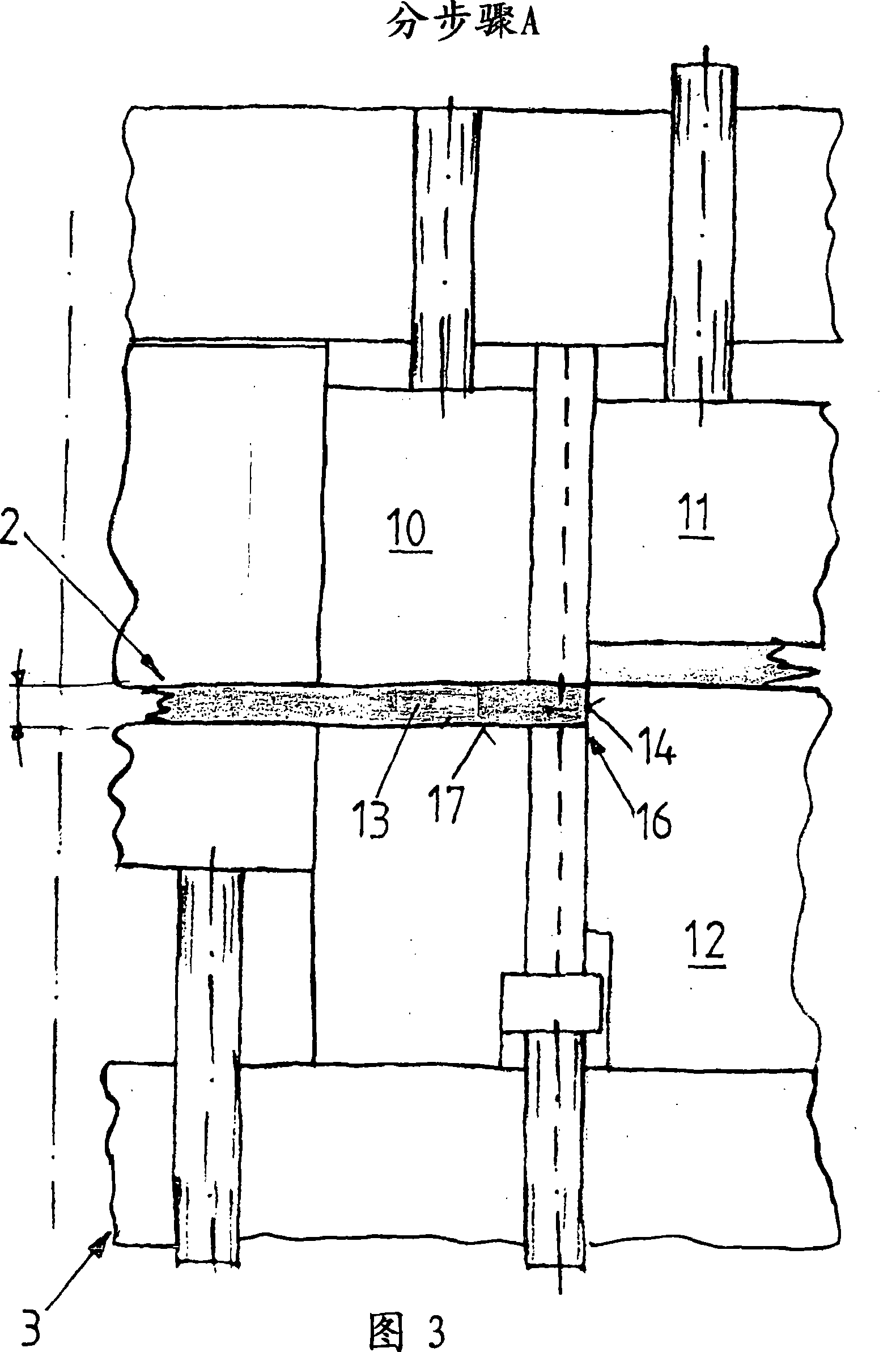

[0023] The method according to the invention is to produce a workpiece 1 , here a toothed part with a greater thickness d, for example 6.5 mm, from a stamped strip 2 by fine blanking. The basic structure of the fine blanking die 3 corresponds to the known prior art. Therefore, no detailed description is required. Therefore, only the special features of the mold are given below.

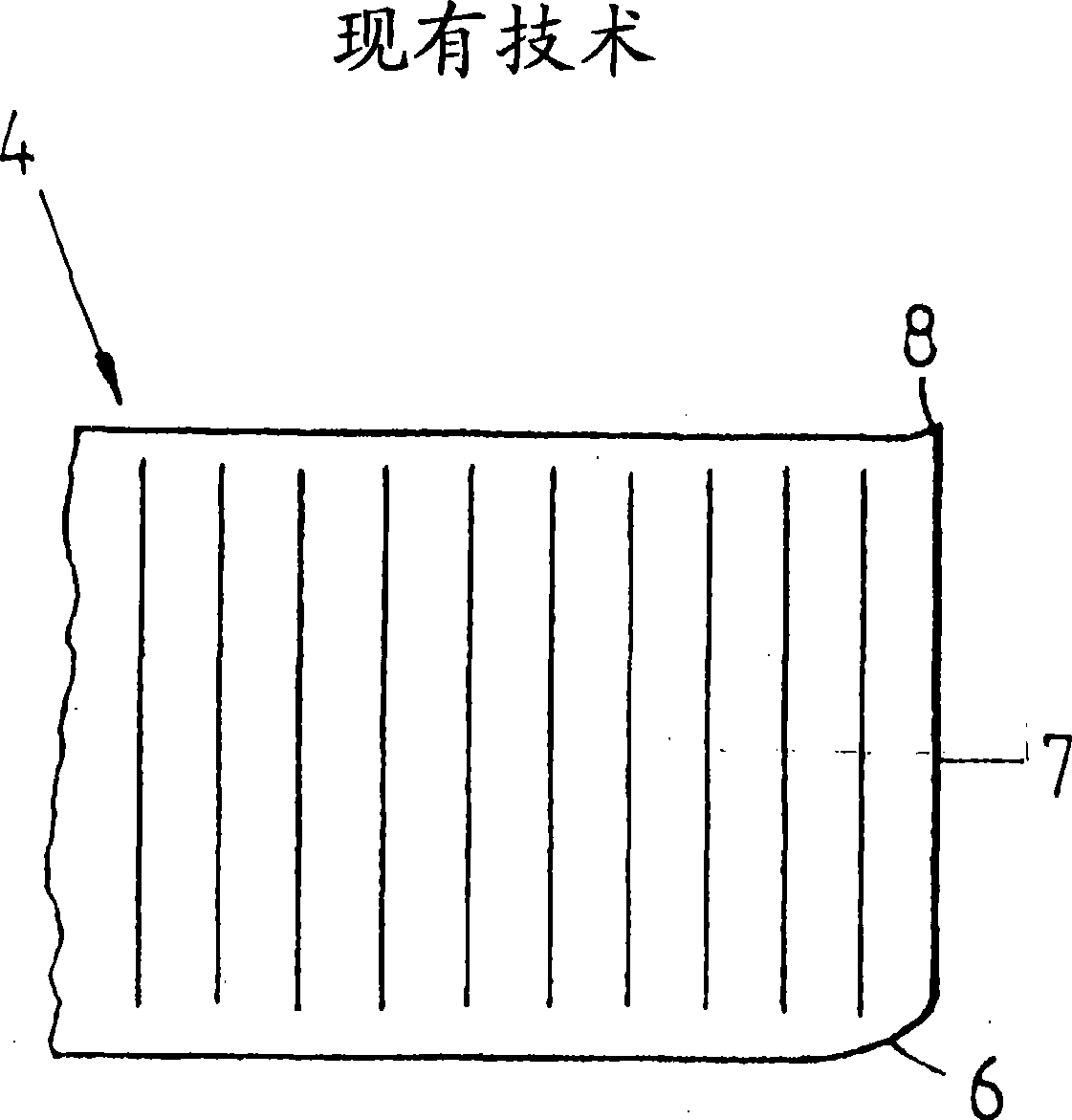

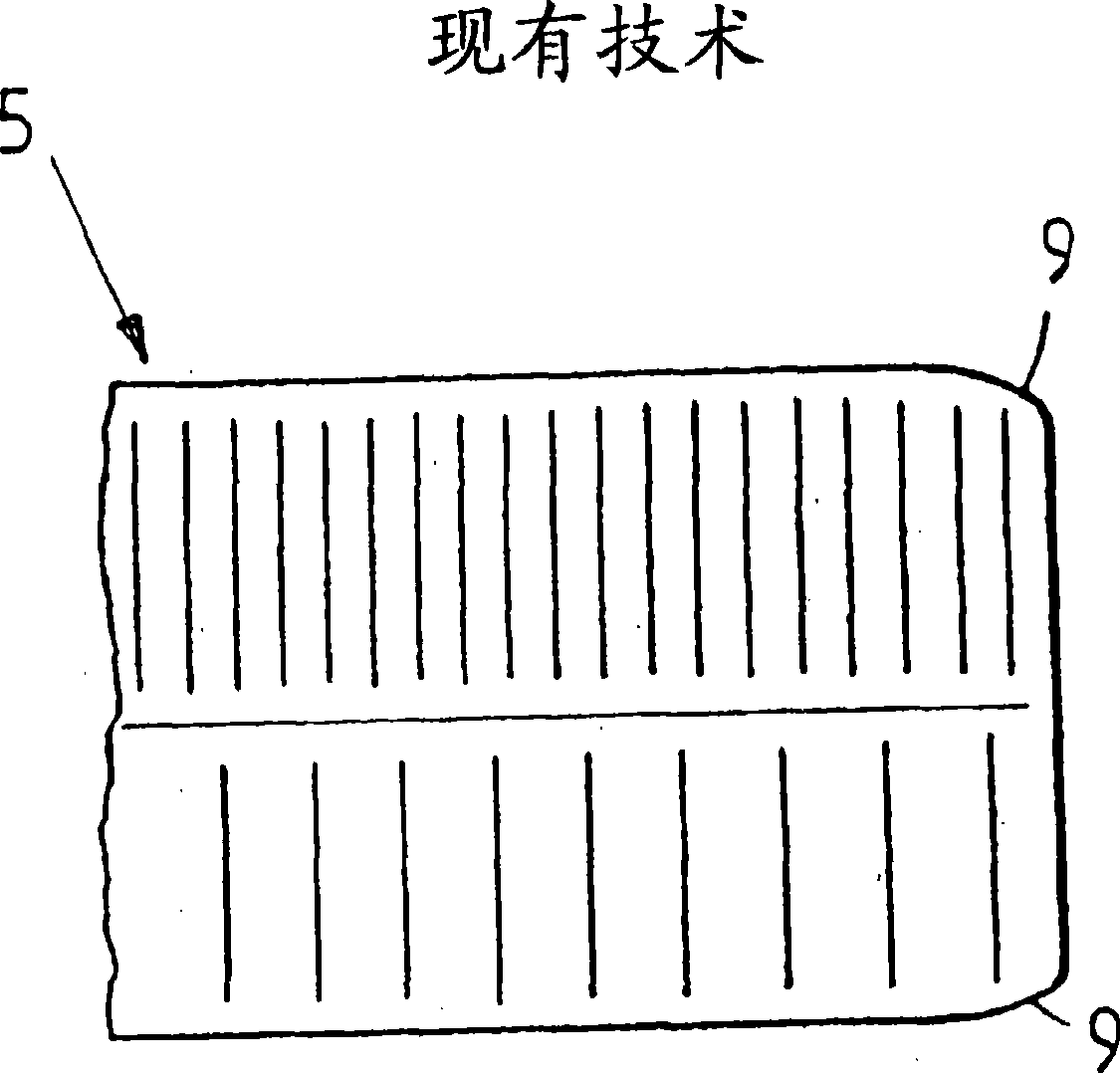

[0024] figure 1 with 2 The blanking geometry of a fine-blanked and counter-fine-blanked component 4 or 5 known from the prior art according to DE 39 31 320 C1 is shown. The fine blanked part 4 has a blunt area 6 , a smooth blanked area 7 and burrs 8 , wherein the burrs 8 are located on the side facing away from the blunt area 6 . It can be seen from the blanking geometry of the reverse fine blanking part 5 that during reverse fine blanking sags 9 are formed on both sides, so that sharp-edged parts, such as toothed parts, cannot be produced with the necessary dimensional stability and precision.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com