Composite concrete expanding agent

An expansion agent and concrete technology, which is applied in the field of concrete and mortar, can solve the problems of absolute shrinkage, concrete structure cracks, high production requirements, etc., and achieve the effects of improving concrete strength, good water retention, and avoiding voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

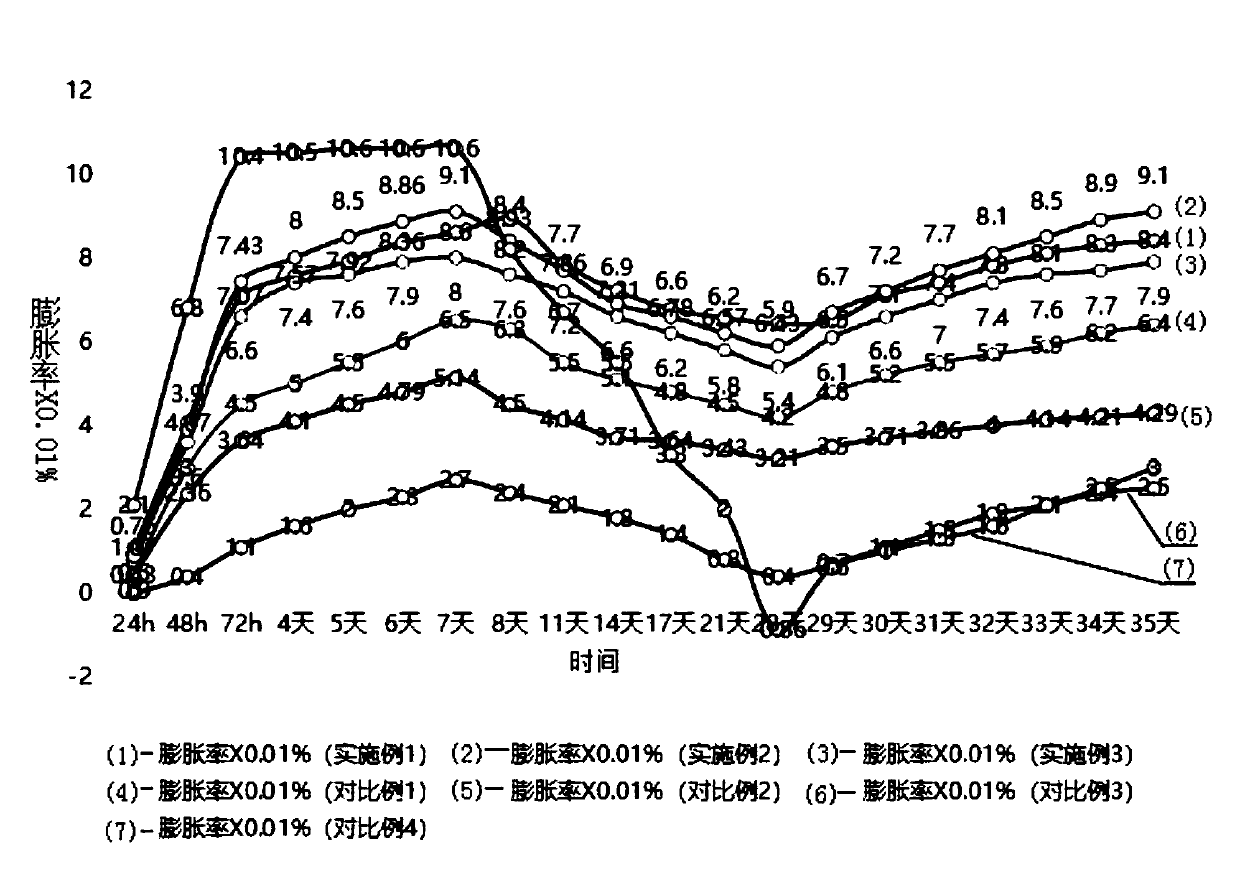

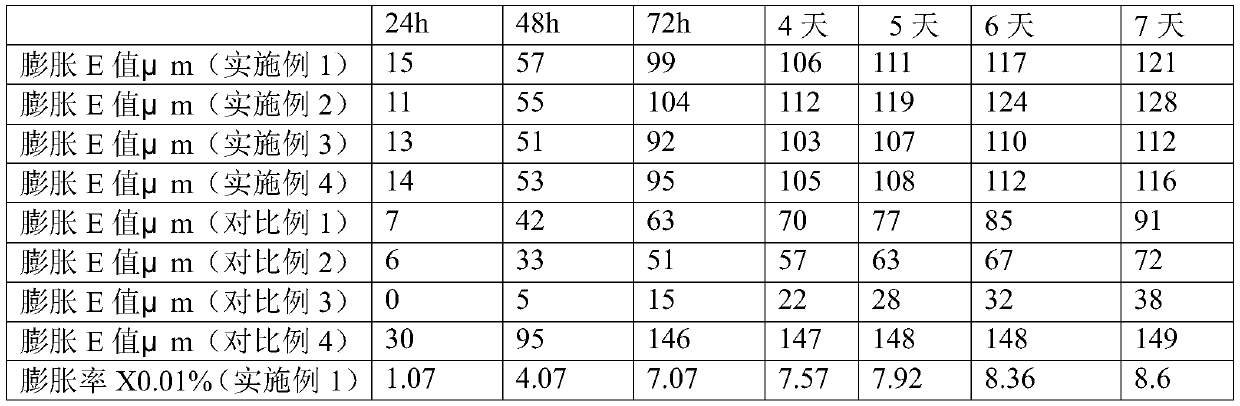

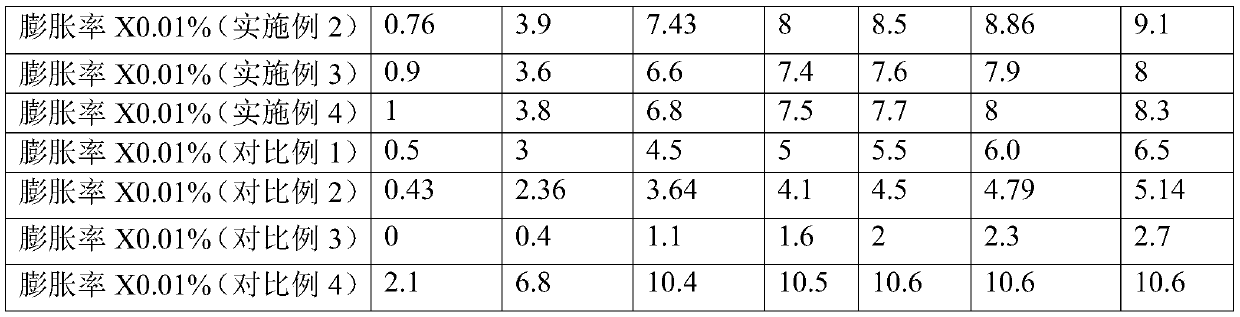

Examples

Embodiment 1

[0028] A composite concrete expansion agent is composed of the following raw materials in parts by weight: 30 parts of A-type quicklime, 40 parts of B-type quicklime, 12 parts of sulfur-aluminum cement, 18 parts of anhydrite, and 0.4 parts of water-retaining agent.

[0029] The type A quicklime is quicklime with a calcium oxide content greater than 80%.

[0030] The type B quicklime is quicklime with a calcium oxide content of 55-65%.

[0031] The water-retaining agent is hydroxypropyl methylcellulose, and its viscosity is 200-400mPa·s.

[0032] The preparation method of the expansion agent of the present embodiment is as follows:

[0033] Weigh 30 parts of A-type quicklime, 40 parts of B-type quicklime, 12 parts of sulfur-aluminum cement, 18 parts of anhydrite, and 0.4 parts of water-retaining agent in powder form and mix them uniformly to obtain the expansion agent of this example. agent.

Embodiment 2

[0035] A composite concrete expansion agent is composed of the following raw materials in parts by weight: 20 parts of A-type quicklime, 50 parts of B-type quicklime, 12 parts of sulfur-aluminum cement, 18 parts of anhydrite, and 0.4 parts of a water-retaining agent.

[0036] The type A quicklime is quicklime with a calcium oxide content greater than 80%.

[0037] The type B quicklime is quicklime with a calcium oxide content of 55-65%.

[0038] The water-retaining agent is hydroxypropyl methylcellulose, and its viscosity is 200-400mPa·s.

[0039] The preparation method of the swelling agent of this embodiment is the same as that of Example 1.

Embodiment 3

[0041] A composite concrete expansion agent is composed of the following raw materials in parts by weight: 20 parts of A-type quicklime, 40 parts of B-type quicklime, 16 parts of sulfur-aluminum cement, 24 parts of anhydrite, and 0.4 parts of water-retaining agent.

[0042] The type A quicklime is quicklime with a calcium oxide content greater than 80%.

[0043] The type B quicklime is quicklime with a calcium oxide content of 55-65%.

[0044] The water-retaining agent is hydroxypropyl methylcellulose, and its viscosity is 200-400mPa·s.

[0045] The preparation method of the swelling agent of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com