Novel welding device

A welding device, a new type of technology, applied in auxiliary devices, welding equipment, metal processing, etc., can solve problems such as shortened service life, potential safety hazards, and insecurity, and achieve the effects of improving safety, increasing service life, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

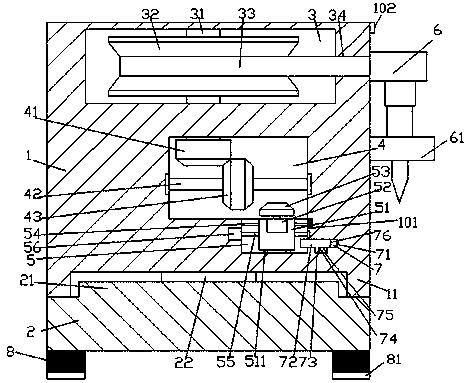

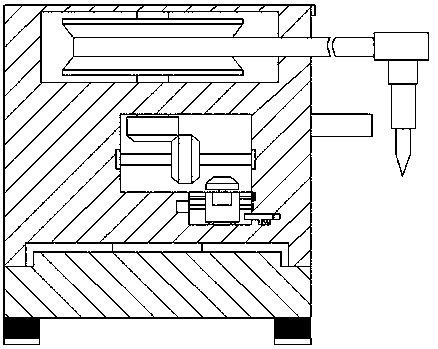

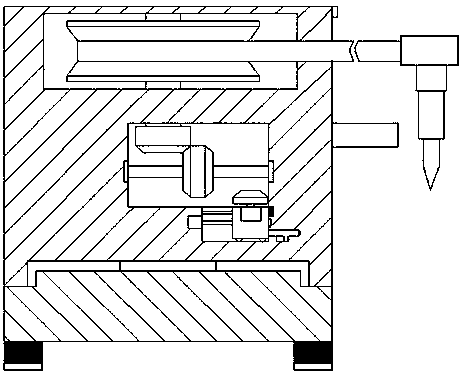

[0022] Such as Figure 1-Figure 6 As shown, a new type of welding device of the present invention includes a base body 2 and a body 1 installed above the base body 2. The body 1 is provided with a first cavity 3, and the right side of the first cavity 3 is provided with Through the groove 34 passing through the outer wall of the body 1 and communicating with the first cavity 3, the body 1 at the bottom of the first cavity 3 is provided with a second cavity 4, and the second cavity The inner bottom of the right side of the chamber 4 is provided with a first sliding groove 5, and the inner wall of the right side of the first sliding groove 5 is provided with a second sliding groove 7, and the bottom of the second sliding groove 7 is provided with a guide groove 75, the first revolving pin shaft 31 extending downward and entering the second receptacle 4 is provided in the first cavity 3, the first revolving pin shaft in the first cavity 3 The outer surface of 31 is fixed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com