Variable diameter type drift size gauge tool

A well gauge and variable diameter technology, which is applied in wellbore/well components, earthwork drilling and production, etc., can solve the problems that the well gauge cannot be lowered, and the well operation cannot be carried out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

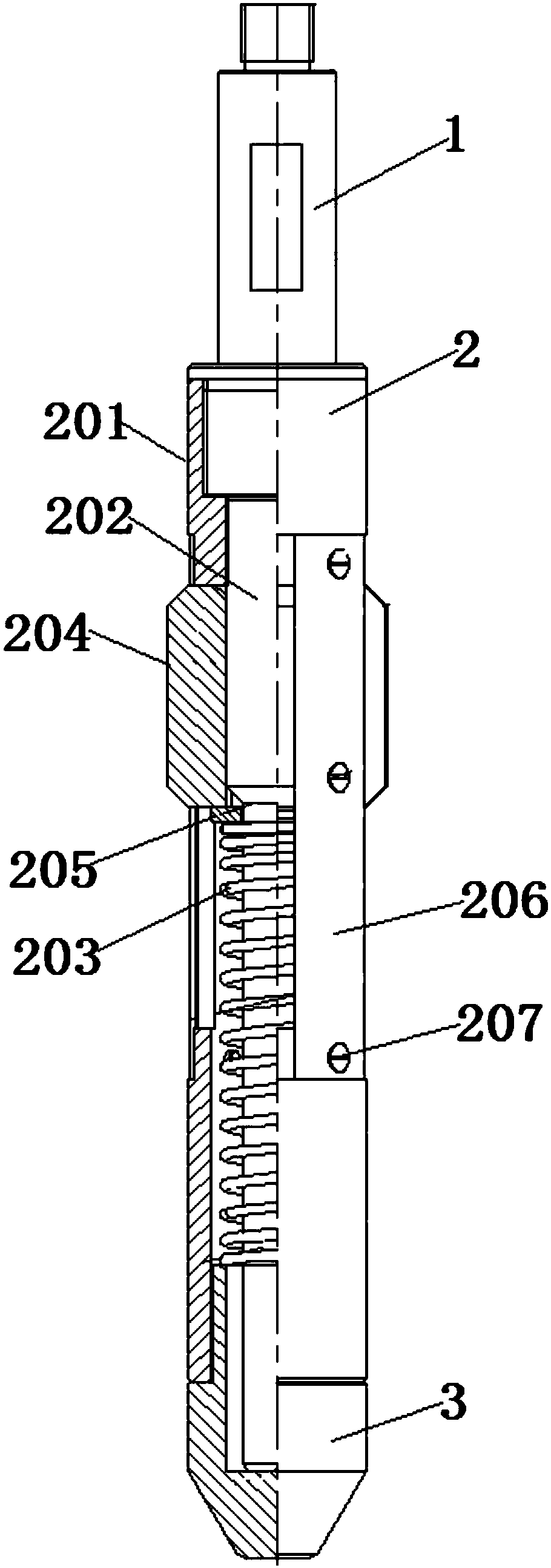

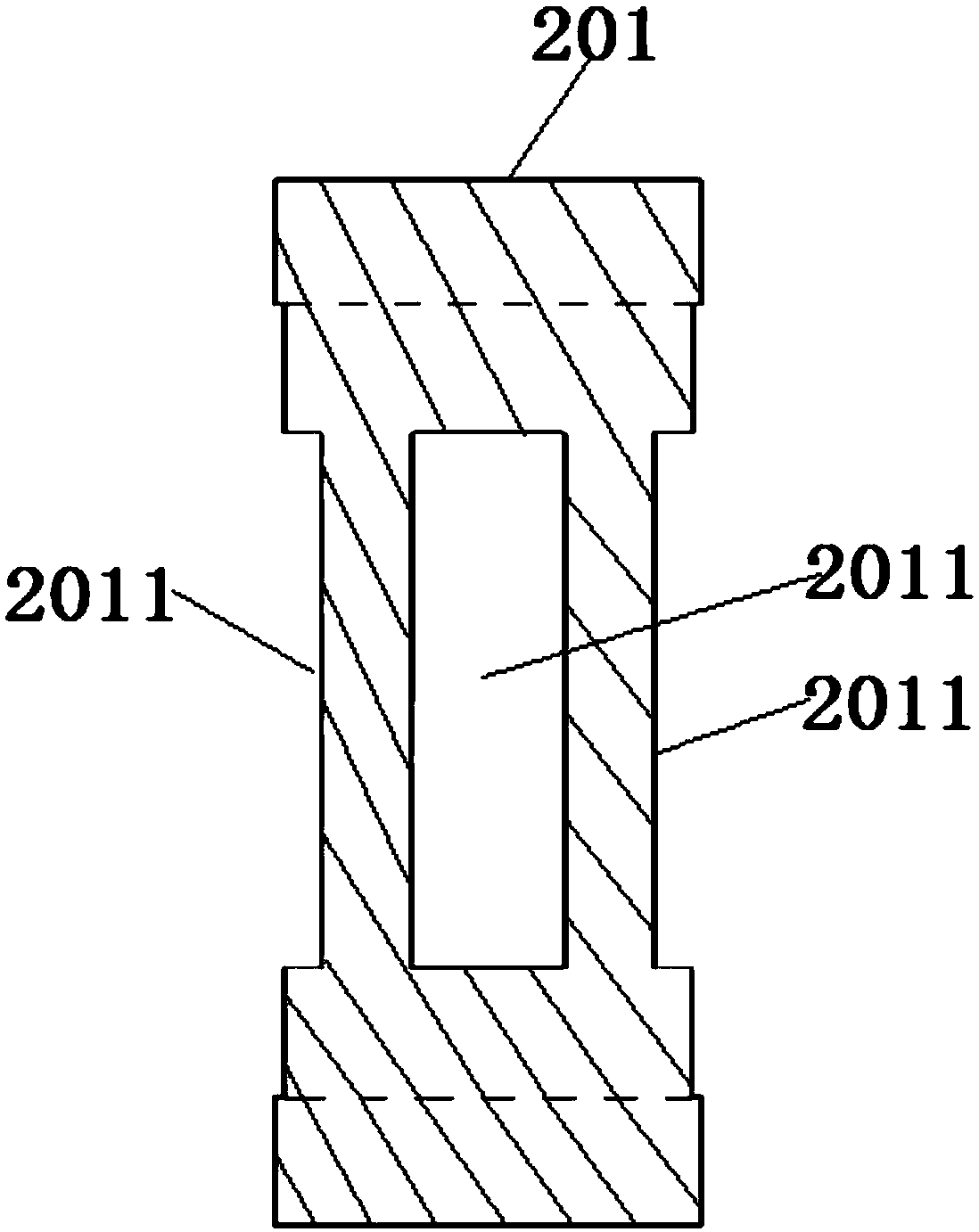

[0053] As an implementation, as attached figure 1As shown, the cylindrical body 2 includes an outer sleeve 201, a variable diameter shaft 202, a spring 203, and a plurality of sliders 204, wherein the two ends of the outer sleeve 201 are connected to the upper joint 1 and the guide head 3 respectively. sleeve 201, and the wall of the outer sleeve 201 is evenly provided with a plurality of longitudinal through grooves 2011 of predetermined length along the circumferential direction (see the attached figure 2 ). The reducing shaft 202 is fixedly sleeved inside the outer sleeve 201, and the reducing shaft 202 includes a large-diameter section and a small-diameter section connected sequentially from top to bottom. The spring 203 is sleeved on the small-diameter section of the reduced-diameter shaft 202 , and the lower end of the spring 203 abuts against the upper end of the guide head 3 . The slide block 204 includes a slide rail part and a well part connected in sequence, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com