A Pneumatic Conveying Powder Flow Velocity Regulator with Adjustable Double-side Baffles

A technology of pneumatic conveying and flow rate adjustment, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of poor pulverized coal flow pattern, easy accumulation of pulverized coal, inflexibility, etc. Uniform and good industrial site installation, reducing the effect of erosion and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

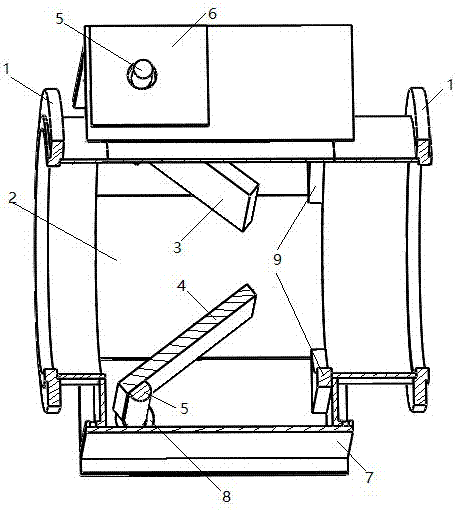

[0033] figure 1 It is a structural representation of the present invention. Such as figure 1 As shown, the pneumatic conveying powder flow rate adjustment device with adjustable bilateral baffles includes a flange (1), a pipe arc (2), an upper adjustable baffle (3), a lower adjustable baffle (4), a rotating Shaft (5), executive mechanism (6) and sealed case (7); characterized in that: the adjustable baffles (3, 4) can rotate within 0 to 90 degrees; the rotating shaft (5) and A sealing ring device (8) is provided between the sealed box shells (7) to ensure the tightness of the pipeline and the powder will not leak during the adjustment of the operation with powder. The windward side of the sealed box shell (7) is provided with a windward liner (9) to prevent wear and erosion of the device by powder during long-term operation.

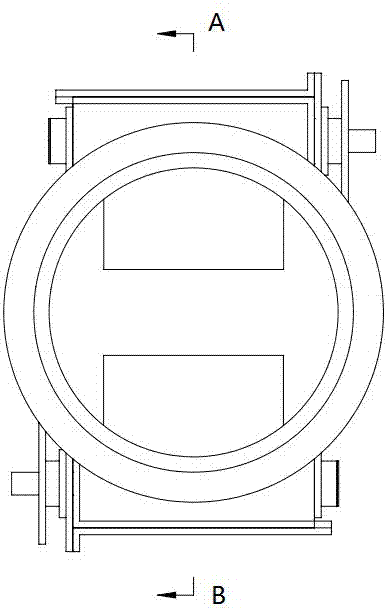

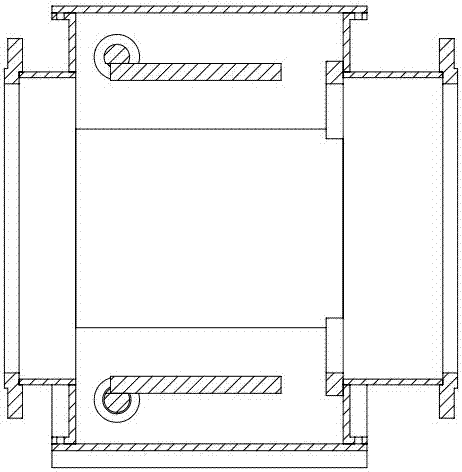

[0034] figure 2 It is a side view of the present invention. Such as figure 2 As shown, the pneumatic conveying powder flow rate adjustment devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com