Oxide thin film transistor type resistance meter

A technology for oxide thin film and resistance measurement, which is applied in the direction of transistors, measuring devices, measuring electrical variables, etc., can solve problems such as inability to measure continuous resistance, and achieve the effect of improving the accuracy of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

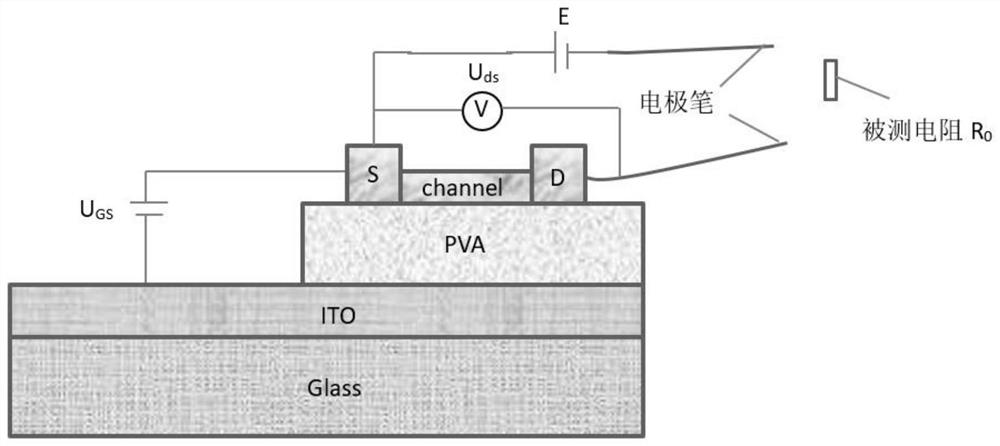

[0023] A method for preparing an oxide thin film transistor type resistance meter of the present invention comprises the following steps:

[0024] 1. Clean a piece of ITO conductive transparent glass coated with ITO coating;

[0025] 2. Prepare a layer of PVA solid electrolyte film as a gate dielectric on the ITO transparent glass coated with the ITO coating side;

[0026] 3. Prepare the source electrode, drain electrode and channel on the PVA gate dielectric by magnetron sputtering method;

[0027] 4. Use the welding method to connect the electrode pen with the source electrode and the drain electrode respectively.

Embodiment 1

[0029] 1. Preparation

[0030] 1. Use deionized water to clean the beaker;

[0031] 2. Use alcohol to clean the ITO glass sheet by ultrasonic wave, the cleaning time is 10 minutes, and the cleaning is repeated three times;

[0032] 3. Take out the cleaned ITO glass sheet, rinse it with the aforementioned deionized water, and perform ultrasonic cleaning. The cleaning time is 10 minutes, and the cleaning is repeated three times;

[0033] 4. Take out the cleaned glass piece and use a nitrogen gun to remove excess water stains on the glass surface;

[0034] 5. Finally, use the electric meter to test to judge the side of the glass with ITO coating, and mark it;

[0035] 6. Clean the silicon wafer with acetone, the cleaning time is 10 minutes, and perform three cleanings, then rinse with deionized water, and use ultrasonic cleaning, the cleaning time is 10 minutes, and perform three cleanings in total;

[0036] 7. Also use a nitrogen gun to dry the surface of the silicon wafer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com