Screen printing device and screening printing method thereof

A screen printing device and screen printing technology, applied in printing devices, screen printing machines, printing and other directions, can solve problems such as low efficiency, and achieve the effect of simplifying complexity, solving bubble problems, and increasing screen printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

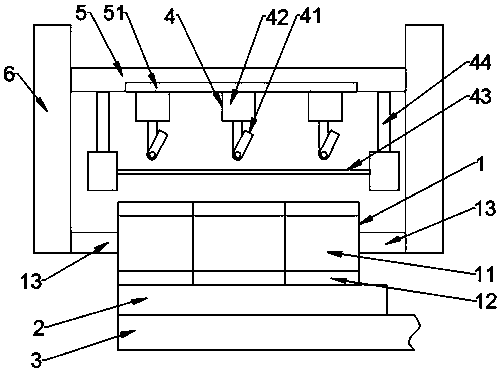

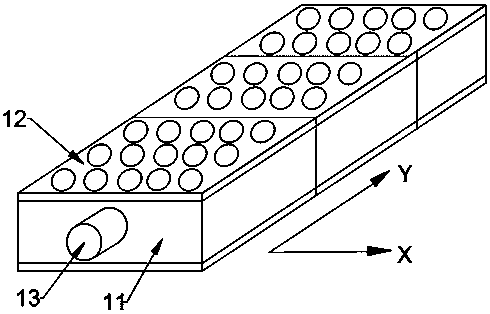

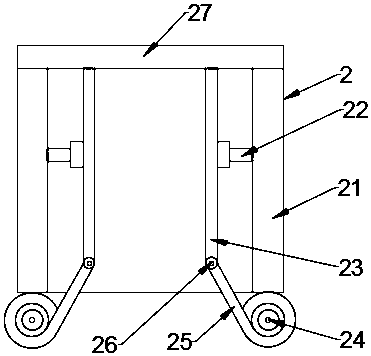

[0032] Such as figure 1 , 2 As shown, a screen printing device includes a pallet 1, a guide structure 2, a conveyor belt 3, a scraper member 4, a beam 5, and a lifting arm 6. The layer 12 is arranged on the upper surface and the lower surface of the rotating plate 11, and is uniformly provided with suction holes at the same time. 12 is axis rotation, when the silk screen printing device performs silk screen printing, the top of the guide structure 2 is flush with the lower surface of the adsorption layer 12 at the lower part, the conveyor belt 3 is arranged at the lower part of the guide structure 2, and the scraper part 4 is arranged at Above the supporting plate 1, a mesh plate 43 is provided between the scraper part 4 and the supporting plate 1. The scraper part 4 includes a telescopic cylinder 42 and a scraper 41. The angle between the scraper 41 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com