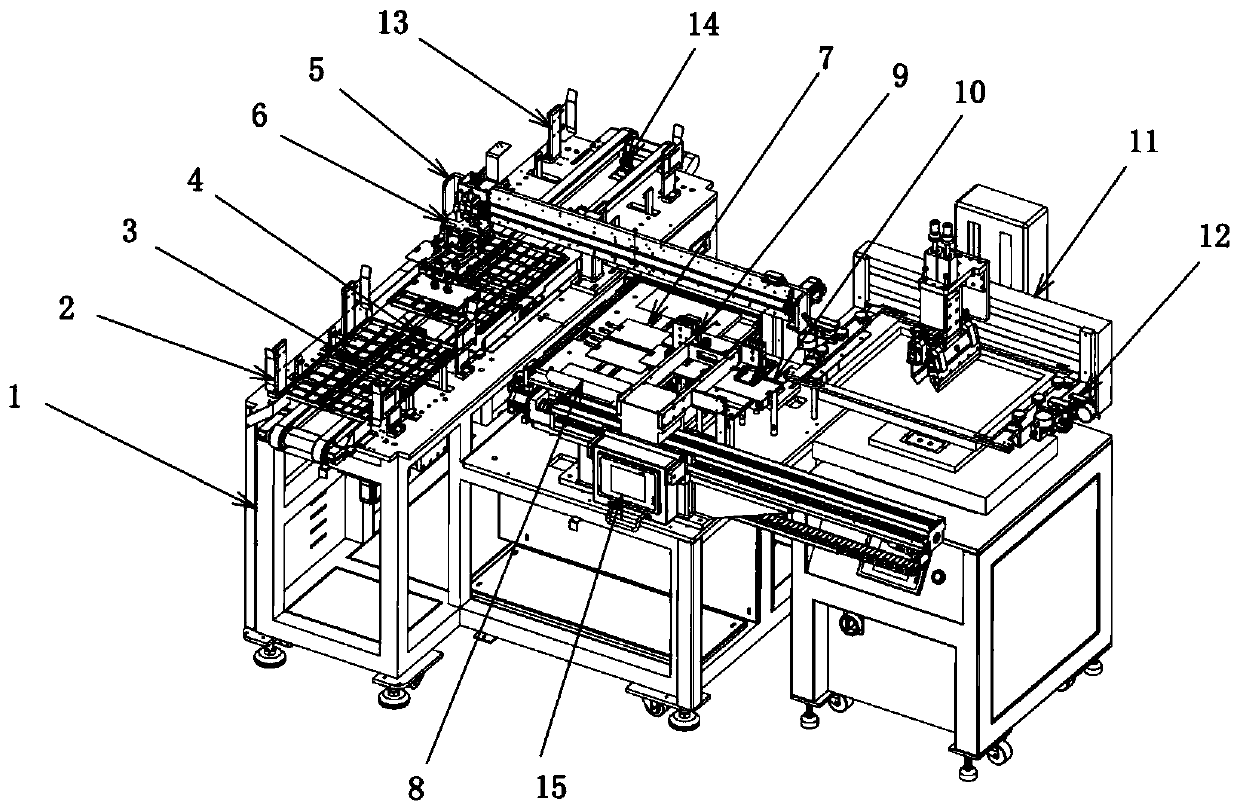

High-precision single-pass double-sheet automatic screen printing machine

A semi-automatic screen printing machine, screen printing machine technology, applied in the direction of screen printing machines, printing machines, screen printing, etc., can solve the problems of low printing accuracy, inconvenient maintenance, affecting positioning accuracy, etc., to reduce maintenance difficulty and save The effect of site cost and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

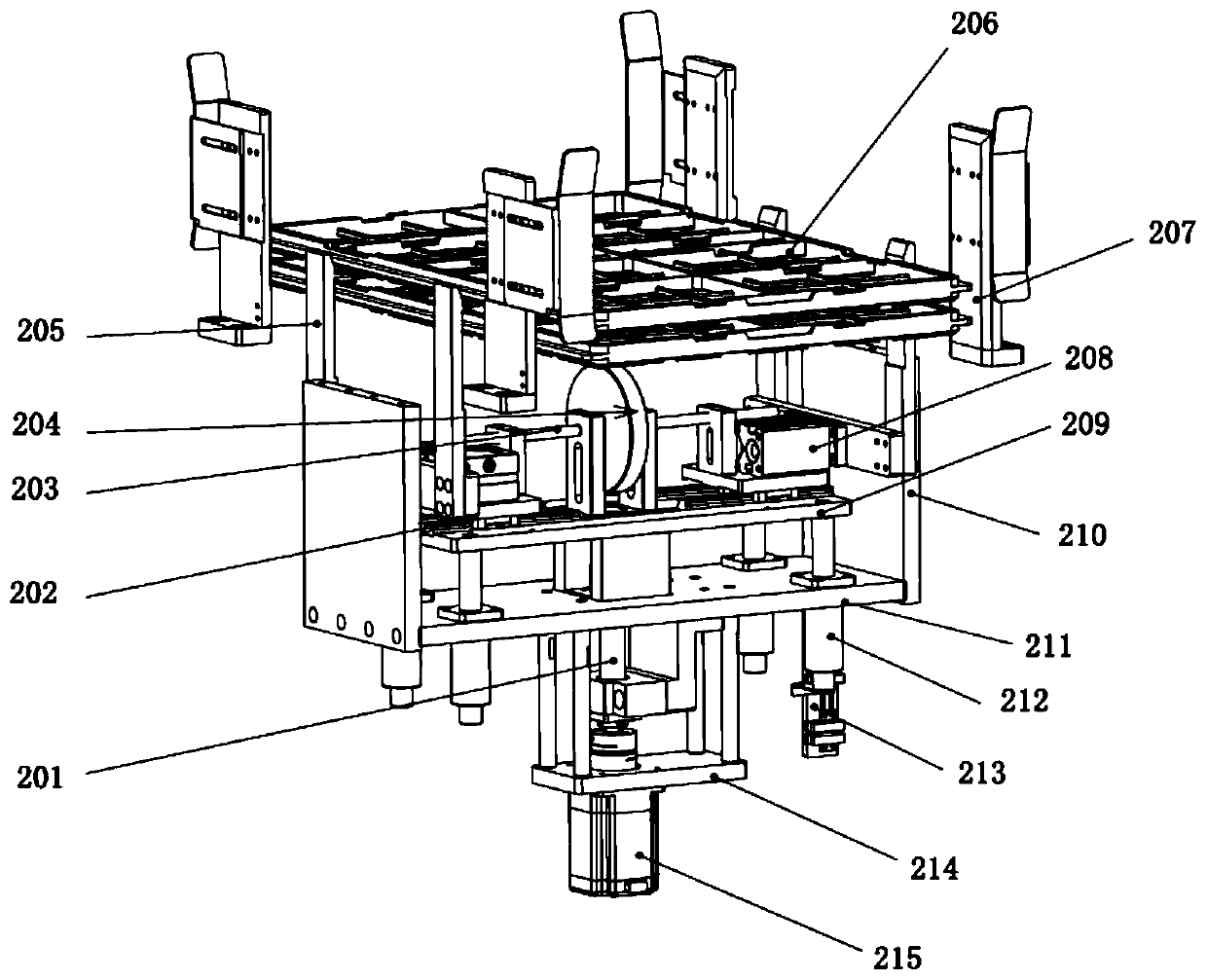

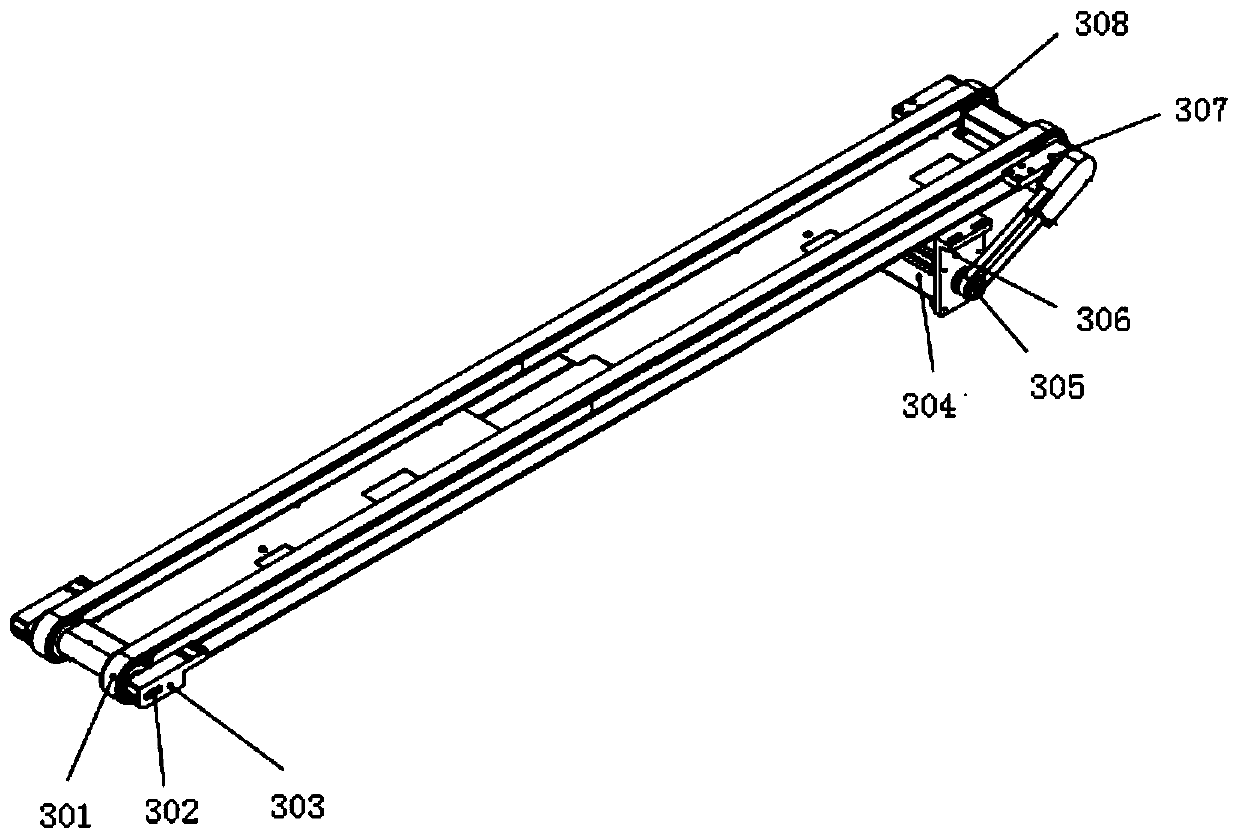

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings. In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of claimed subject matter. It will be understood, however, by those skilled in the art that claimed subject matter may be practiced without these specific details. In addition, it is obvious that the following descriptions are only some embodiments of the present invention, and those skilled in the art can obtain other embodiments based on these embodiments without creative efforts. In addition, methods, devices, or systems that would be known by one of ordinary skill have not been described in detail so as not to obscure claimed subject matter.

[0037] Reference in the specification to "one embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com