Pre-storing device for building materials

A building and material storage technology, applied in packaging, transportation and packaging, bottle/can components, etc., can solve the problems of time consumption, influence of surrounding residents, waste of electricity, etc., to reduce processing time, facilitate processing, increase The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

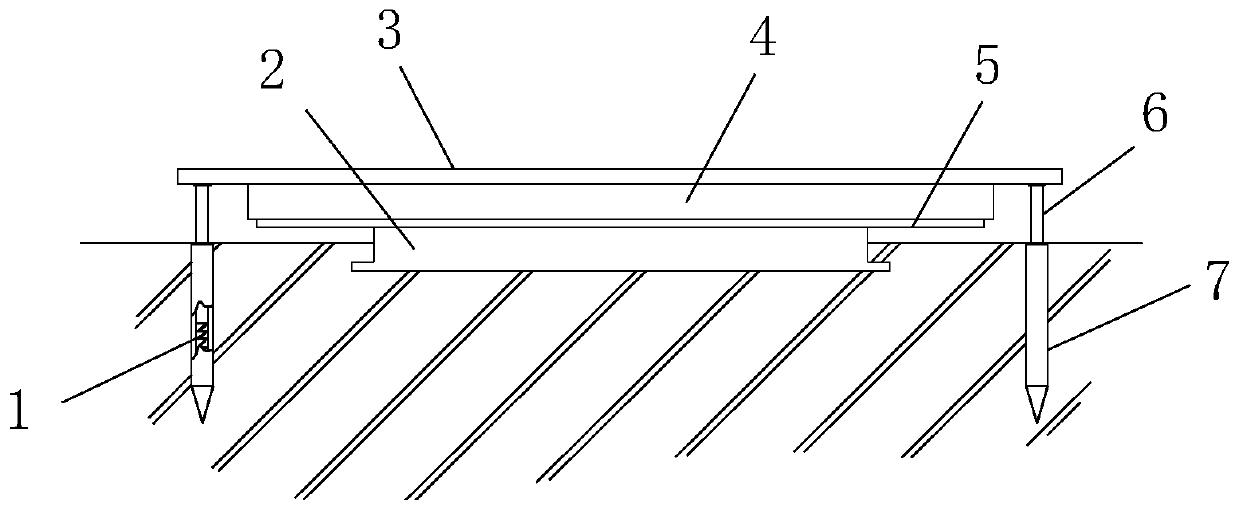

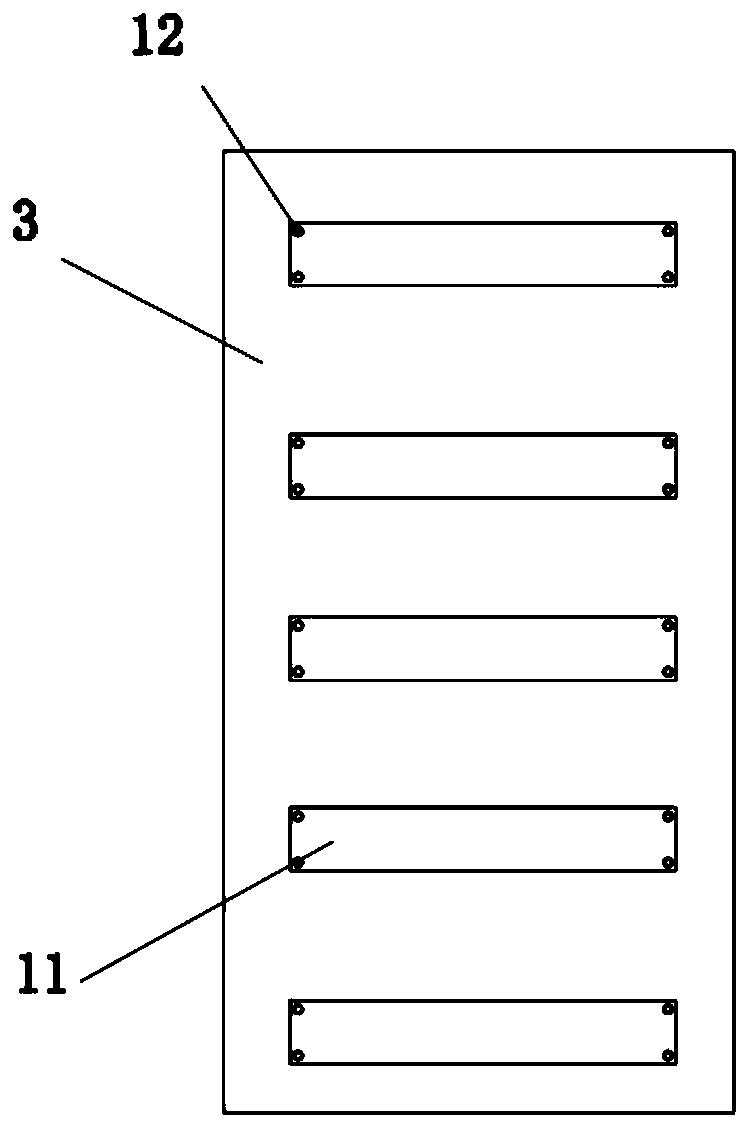

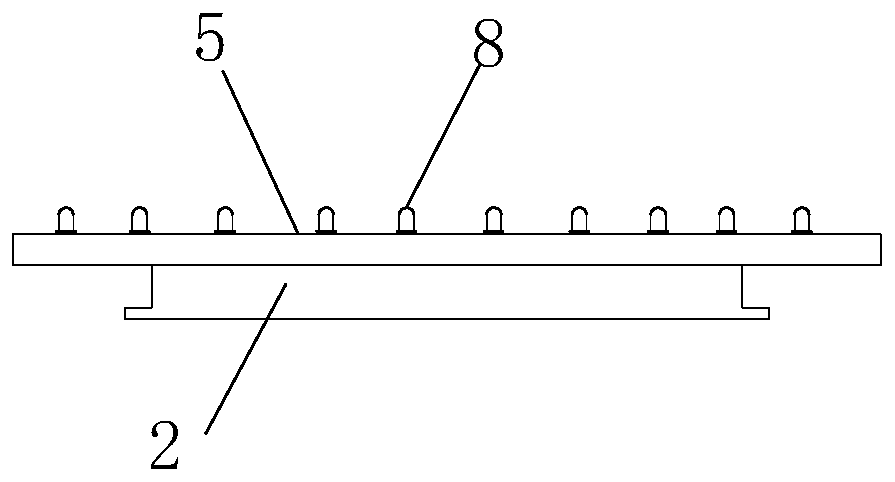

[0020] Such as figure 1 As shown, the pre-storage device of this building material includes a pre-storage device, which includes a suspension laying on the road surface of the vehicle, including a support plate 3, more than one buried shaft sleeve 7, telescopic rod 6, sealing Plate and a material storage box 4, the material storage box 4 is fixedly installed on the bottom of the support plate 3, the bottom opening end of the material storage box 4 is sealed by the sealing plate installed at the bottom, and the lower end surface of the entire material storage box 4 is not in contact with the ground , the support plate 3 is arranged on the top of the material storage box 4 and forms a running surface for the vehicle on its upper end surface, the support plate 3 is arranged on the soil road surface, and building materials (not shown) are stored in the material storage box .

[0021] The buried shaft sleeves 7 are inserted and fixed on both sides of the bottom of the support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com