Trolley transmission mechanism with wheel track being adjusted by studs

A technology of transmission mechanism and stud, which is applied in the directions of traveling mechanism, load hanging element, transportation and packaging, etc., to achieve the effect of novel structure and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

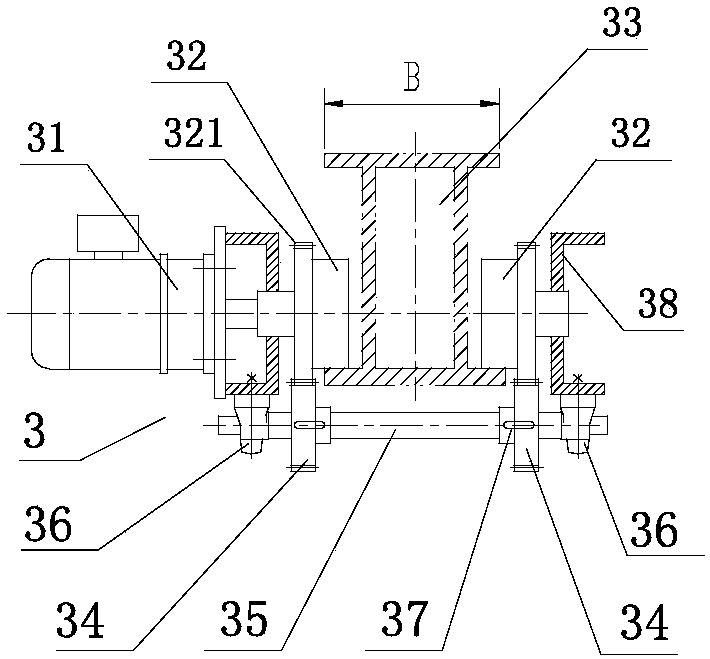

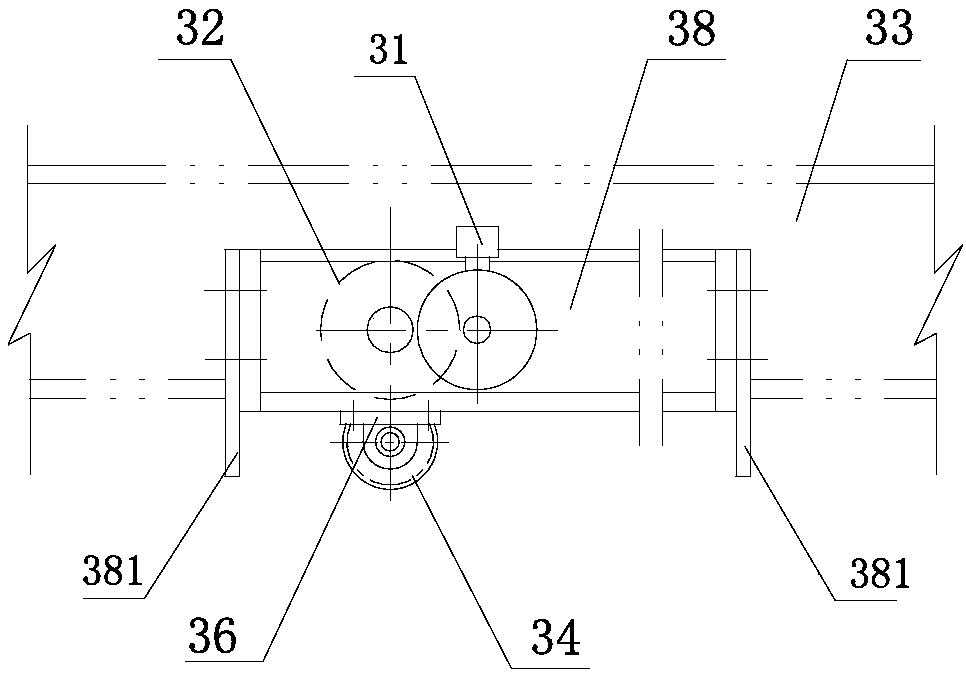

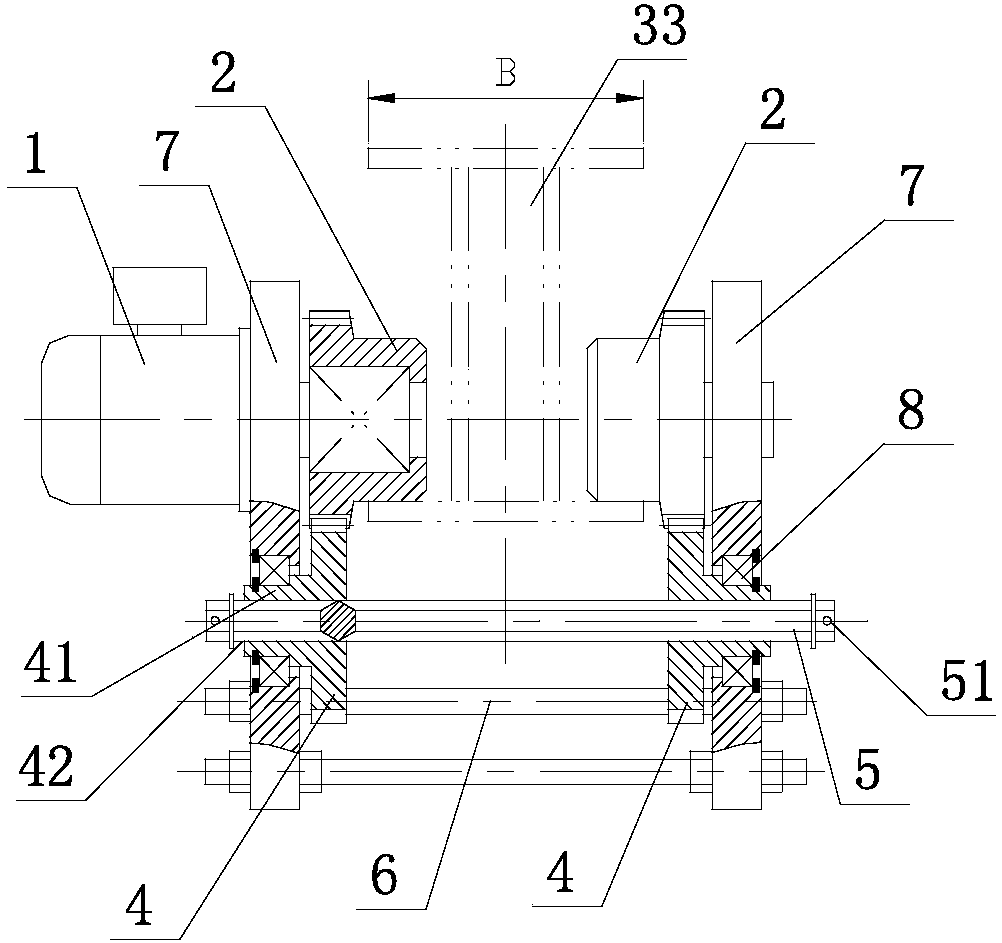

[0012] Such as image 3 , Figure 4 As shown, a trolley transmission mechanism whose wheelbase is regulated by studs, the transmission mechanism includes a motor 1, a driving wheel 2, a transition gear 4, and a driven wheel 9; the driving wheel 2 has a single wheel rim, and the wheel rim With gears; the mandrels of the two driving wheels are respectively connected to two body plates 7; the motor 1 is connected to one of the body plates, and the output shaft of the motor is meshed with a gear on the driving wheel; Described excessive gear is connected with the outer meshing of described driving wheel, and is under driving wheel; Two described driven wheels 9 are respectively connected on two body plates 7; Between described two body plates 7 there are multiple A shaft extension 41 is provided on one side of the transition gear 4, and the outer diameter of the shaft extension is connected to the above-mentioned body plate 7 through a bearing 8, and the bearing 8 and the transit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com