3D printer spraying nozzle structure

A 3D printing and nozzle technology, applied in coating devices, additive processing, etc., can solve problems such as high personnel requirements, complex 3D printing model structure, affecting 3D printing applications, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

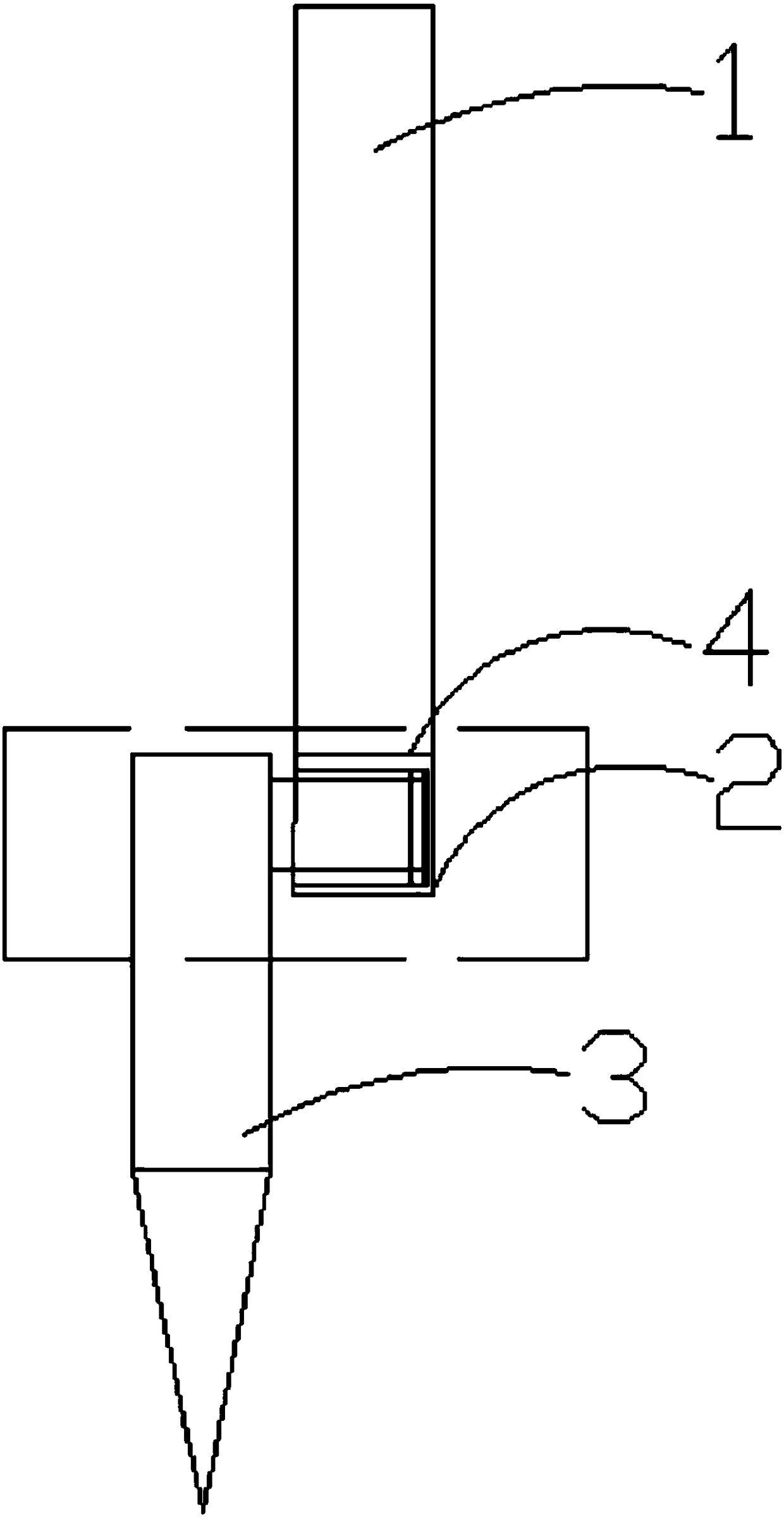

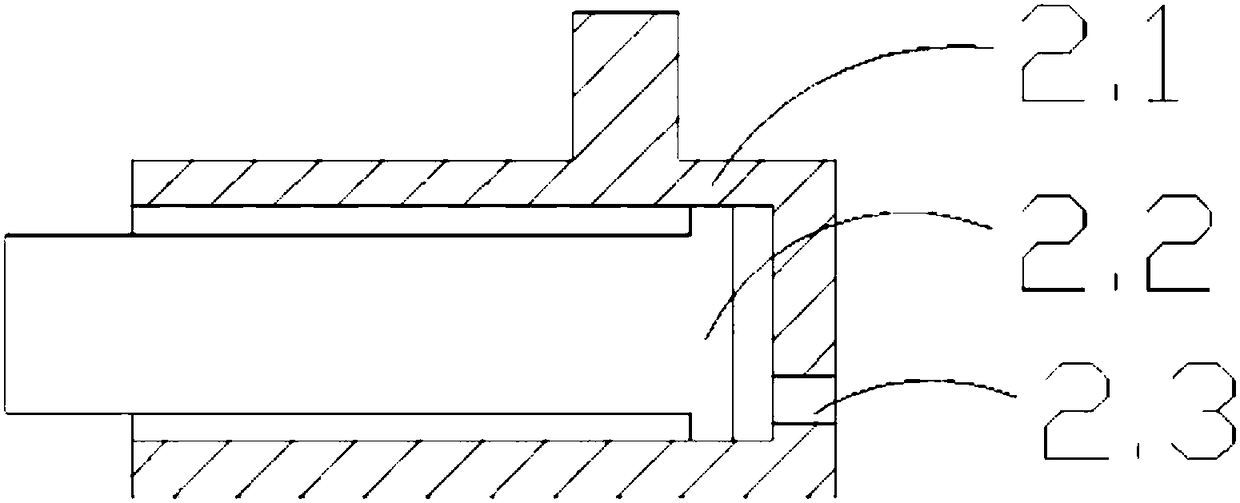

[0012] Such as figure 1 and 2 As shown, a 3D printing nozzle structure includes a main connecting column 1, a secondary connecting column 2 and a nozzle 3, the lower end of the main connecting column 1 is provided with a bearing 4, the bearing 4 is a deep groove ball bearing, and the main connecting column 1 The bearing 4 is connected to one end of the auxiliary connecting column 2; the upper part of the outer body 2.1 is provided with a protruding shaft that cooperates with the inner ring of the bearing 4; the auxiliary connecting column 2 rotates 360° around the axis of the main connecting column in (X, Z ) is to print a circular model on the base surface, the secondary connecting column 2 includes an outer body 2.1, a piston movable rod 2.2 and an air hole 2.3, the piston movable rod 2.2 is arranged in the cavity of the outer body 2.1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com