Method for detecting and controlling abnormal speed of coke oven locomotive

A speed and abnormal technology, used in coke ovens, furnace safety devices, petroleum industry and other directions, can solve the problems of lack of speed detection device and speed control method, speed monitoring system detection failure, speed out of control and other problems, to reduce manual labor load , Easy for maintenance personnel to grasp, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

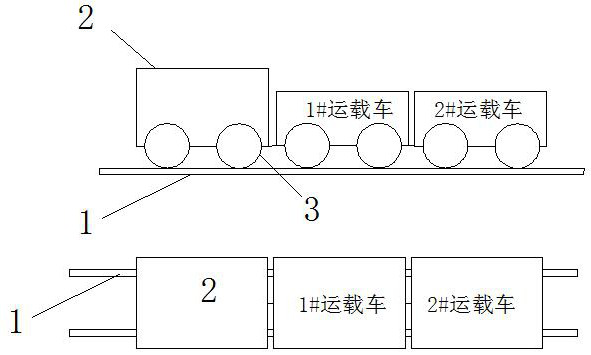

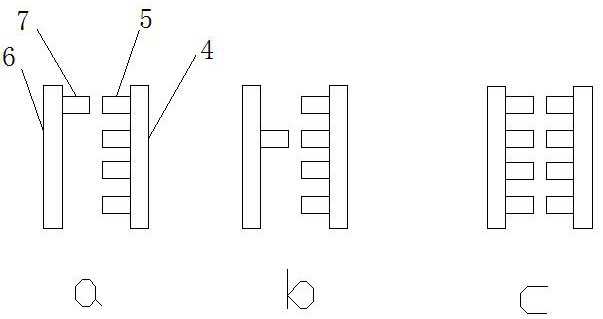

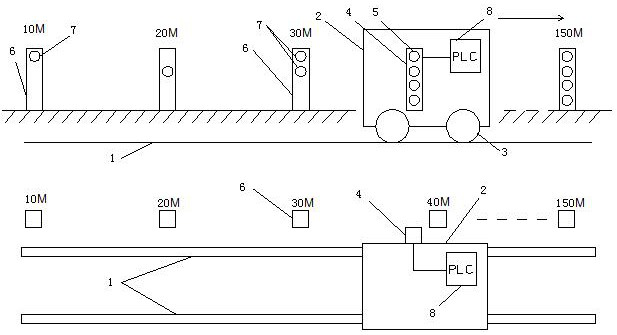

[0018] Embodiment 1: see figure 1 , a method for detecting and controlling the abnormal speed of a coke oven locomotive, the method is as follows: 1) Set a displacement identification device in the deceleration area of the vehicle, the encoding of the displacement identification device adopts the encoding method of 8421 codes, and the signal can be read by the on-board control system , the on-board control system calculates the current position of the vehicle through the read information and performs timing. The displacement identification device such as figure 2 As shown, the on-board control system is composed of ground equipment and on-board equipment. The ground equipment is arranged at fixed points along the running direction of the locomotive. It includes ground brackets and signaling devices 7, and the signaling devices are installed on the ground brackets according to the rule of 8421 yards. Above, the on-board equipment 4 is installed on the locomotive, including t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com