Aluminum alloy shell and preparation method and individual electronic equipment

A technology of aluminum alloy and casing, applied in the field of material chemistry, can solve problems affecting the cleanliness and continuity of the appearance, destroying the metal texture of the fuselage, and destroying the overall structure of the metal fuselage, etc.

Active Publication Date: 2018-07-10

BYD CO LTD

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most mobile phones with metal bodies adopt the method of opening antenna slots and injection molding to solve the problem of signal shielding of the body, such as the upper and lower antenna slots of HTC ONE, and the side antenna slots of iphone5/5s, etc., alth

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

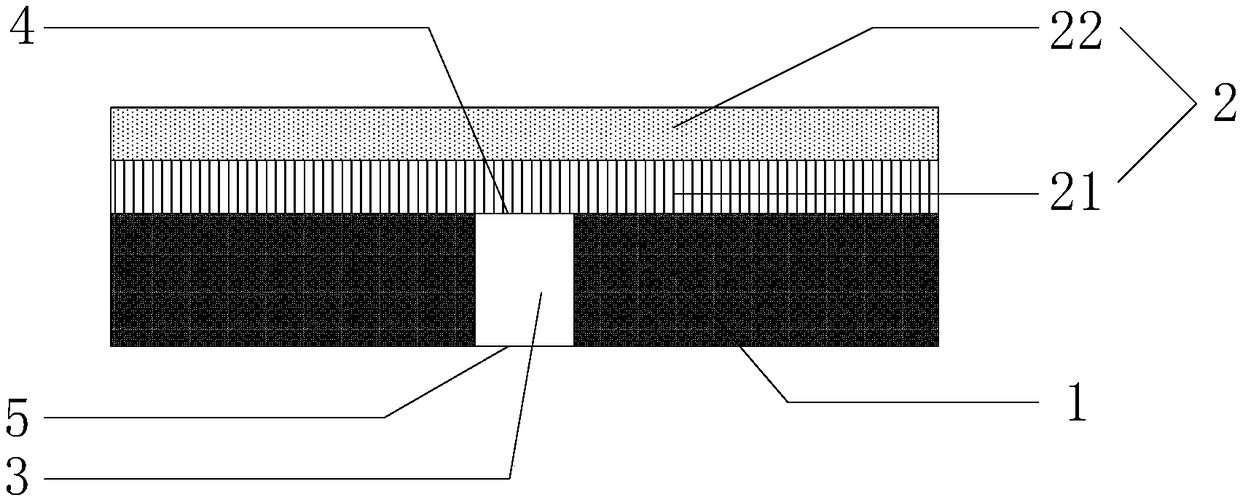

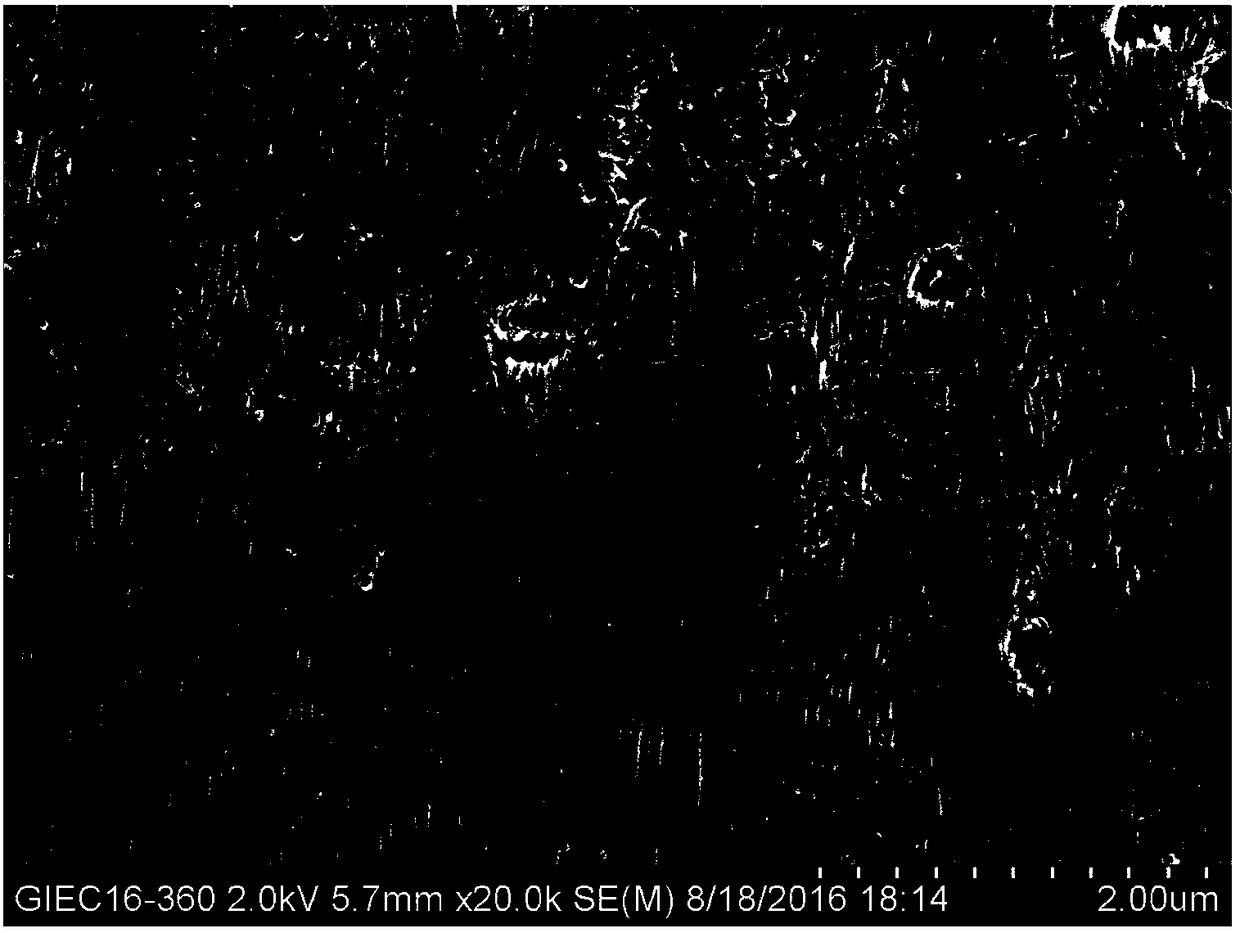

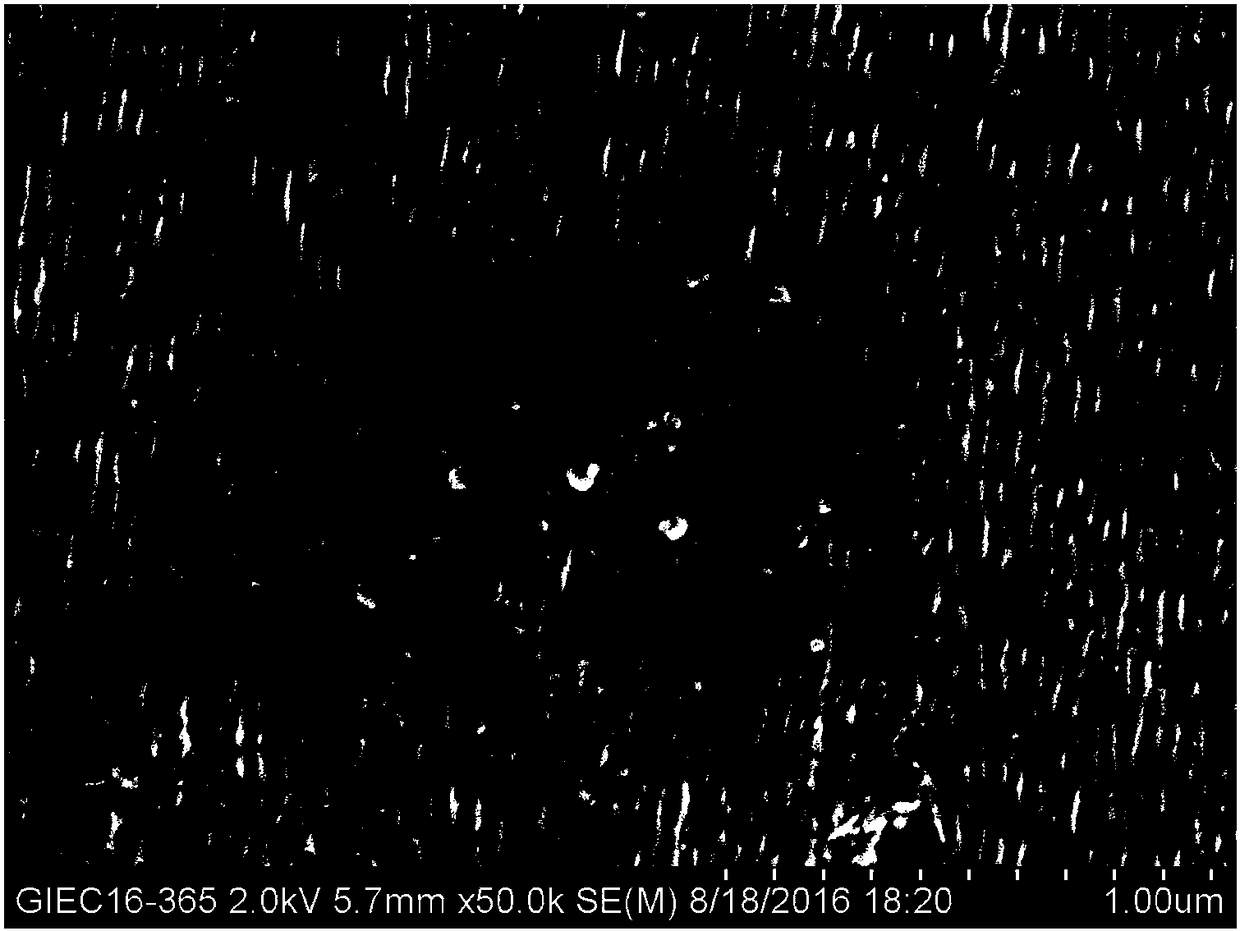

The invention discloses an aluminum alloy shell and a preparation method and individual electronic equipment thereof. The aluminum alloy shell comprises an aluminum alloy substrate (1) and an oxidation film layer (2), wherein a slit (3) is formed in the aluminum alloy substrate (1); the oxidation film layer (2) comprises an inner anode oxidation film layer (21) and an outer anode oxidation film layer (22); the inner anode oxidation film layer (21) is provided with inner anode oxidation film layer nano holes; the outer anode oxidation film layer (22) is provided with outer anode oxidation filmlayer nano holes; and the inner anode oxidation film layer nano holes and the outer anode oxidation film layer nano holes are separately independently filled with dye. When seen from the surface of the outer side of the shell, the aluminum alloy shell is a continuous metal layer, and the slit in the metal layer can serve as an antenna groove. The oxidation film layer on the surface of the metal layer has a good shielding effect, thus, the appearance of the slit is invisible, and the shell is neat and smooth. The aluminum alloy shell has good metal texture.

Description

technical field [0001] The invention relates to the field of material chemistry, in particular to an aluminum alloy casing, a preparation method thereof, and personal electronic equipment. Background technique [0002] The mobile phone antenna is a device used to receive signals on the mobile phone. Currently, most smartphones on the market have built-in antennas, which requires that the back cover of the mobile phone cannot shield the signal. Metal has a strong absorption of electromagnetic waves. When wifi, 2G, and 3G signals are injected into metal materials, absorption and attenuation will occur. Electromagnetic waves cannot reach the signal receiving module, resulting in signal shielding. Therefore, for metal body mobile phones, how to solve the signal shielding problem is one of the keys in its design and manufacture. At present, most mobile phones with metal bodies adopt the method of opening antenna slots and injection molding to solve the problem of signal shieldin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D11/12C25D11/08C25D11/18C25D11/16

CPCC25D11/022C25D11/024C25D11/08C25D11/12C25D11/16C25D11/18H04M1/02H05K5/04C25D11/02C25D11/22

Inventor 王钰廖重重陈梁章乐代灵娜

Owner BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com