Low-stress high-damping railway fastener elastic strip

A railway fastener and high damping technology, which is applied in roads, fixed rails, tracks, etc., can solve the problems of endangering rail transit operation safety and maintenance work, shortening the fatigue life of fastener clips, and fatigue fracture of clips, etc. Achieve the effect of solving the fatigue fracture of the elastic strip, improving the dynamic fatigue life and improving the fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

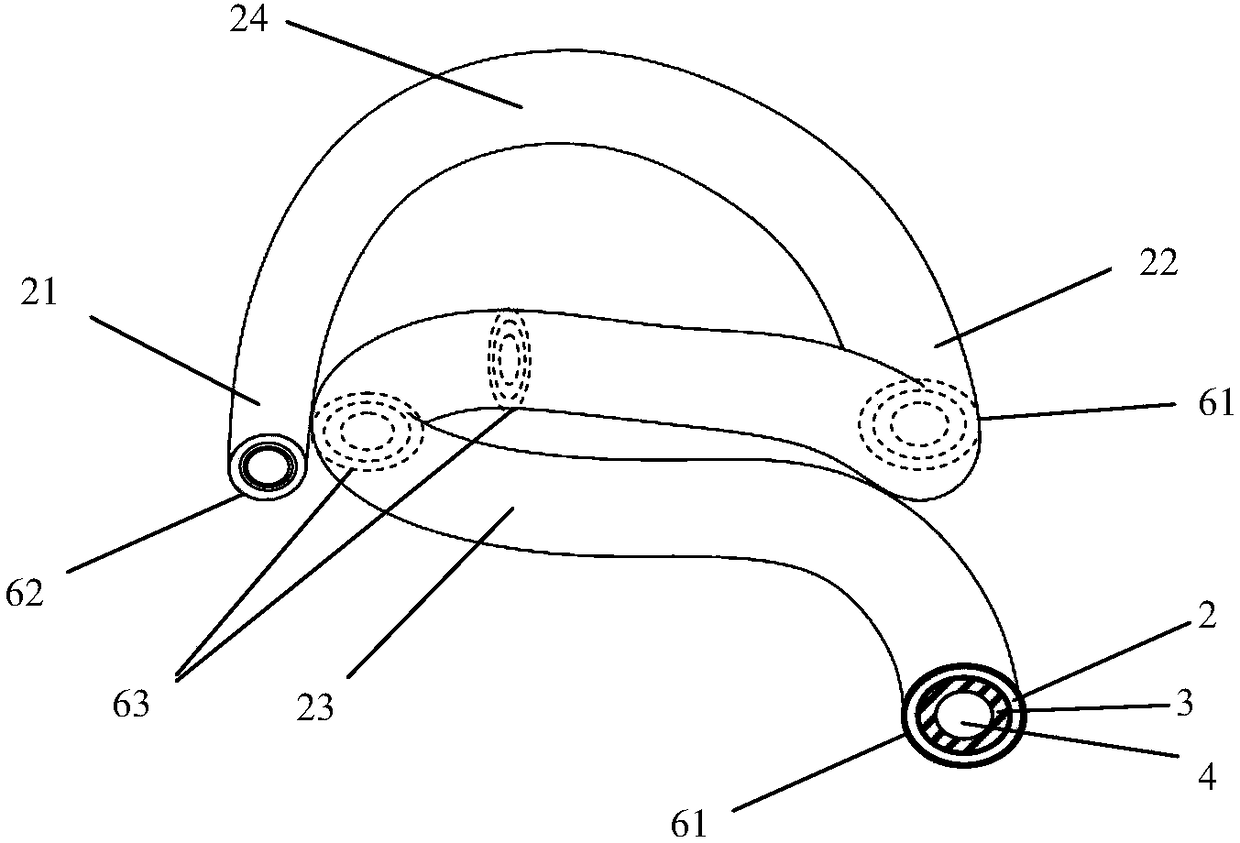

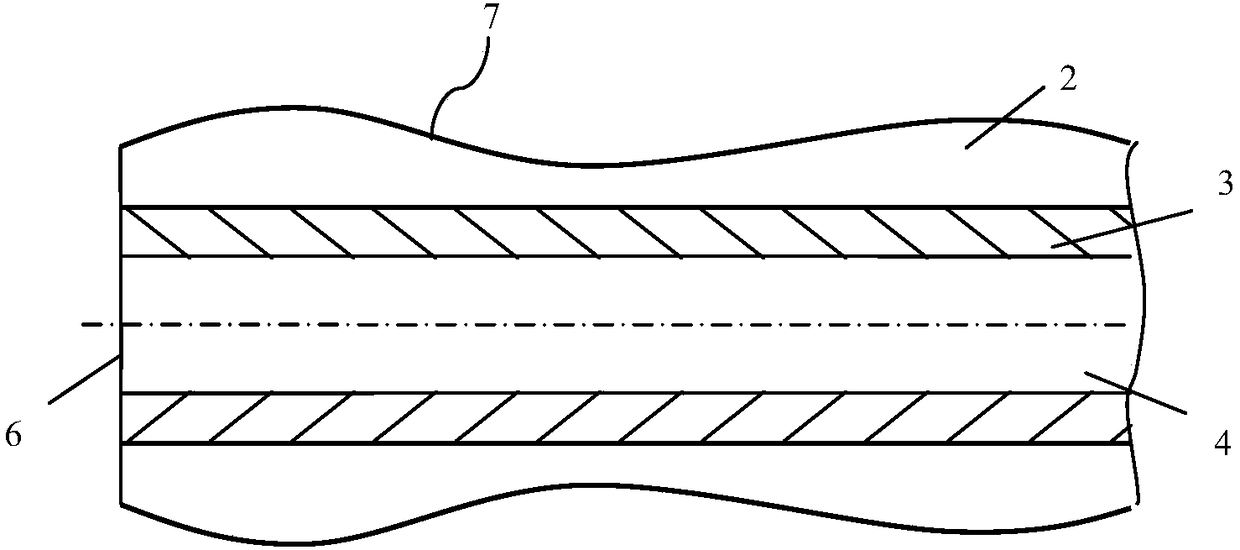

[0031] Such as figure 1 Shown, a kind of low-stress high-damping railroad fastener elastic strip, fastener elastic strip 1 is made of elastic material layer 2 (this material layer is spring steel elastic material layer) of elastic strip matrix, damping elastic material layer 3 and constraining quality layer 4 Composition, wherein the elastic material layer 2 of the elastic strip parent body is a hollow elastic strip, and the damping elastic material layer 3 and the constrained mass layer 4 are successively arranged in the elastic strip inner cavity 12 of the hollow elastic strip (such as Figure 2a-2b As shown), the elastic material layer 2 of the elastic strip parent body, the damping elastic material layer 3 and the constrained mass layer 4 are connected together through the bonding performance of the perfusion type damping material before curing.

[0032] The elastic strip includes an elastic toe 21, an elastic arm 24, an elastic heel 22 and an elastic lock 23 which are seq...

Embodiment 2

[0036] Such as Figure 2a As shown, different from the variable cross-section profile 7 along the centerline direction of the clip in Embodiment 1, the variable cross-section profile in this embodiment is set as a wave shape, corresponding to the installation of the clip on the railway track fastener and the load condition of the working state The stress under the spring is evenly distributed at different positions of the elastic strip, but the variable section coefficient is 1 to 3:1.

Embodiment 3

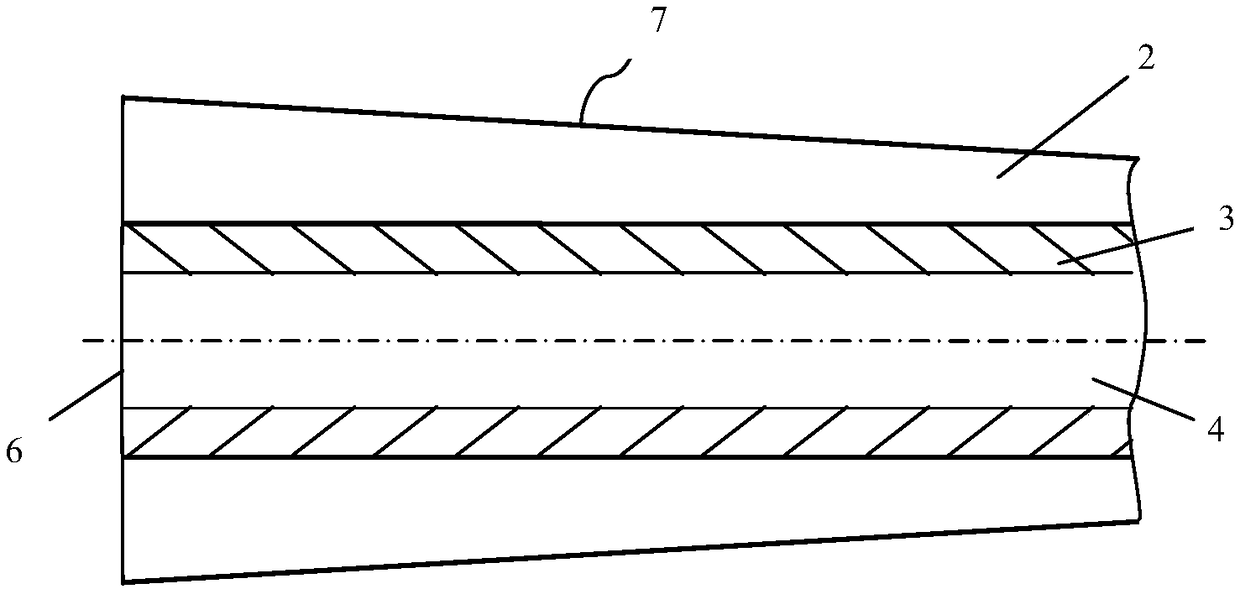

[0038] Such as Image 6 As shown, it is different from the variable cross-section profile 7 along the centerline direction of the elastic strip in Embodiment 1. In this embodiment, the variable section coefficient is 1, and the cross-sectional area of the elastic material layer section 6 of the elastic strip is the same as that of the existing elastic strip. The moment of inertia of the section of the elastic material layer 2 of the parent body of the clip is greater than the moment of inertia of the section of the existing solid clip. The elastic strip inner cavity 12 of the elastic material layer 2 of the elastic strip matrix is not a through hole, but an impermeable cavity arranged in a solid elastic strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com