Novel squid slicing and squid flower making equipment

A technology for slicing and squid, applied in the field of squid slicing and flower cutting equipment, can solve the problems of uneven output, large quantification error, inconvenient packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

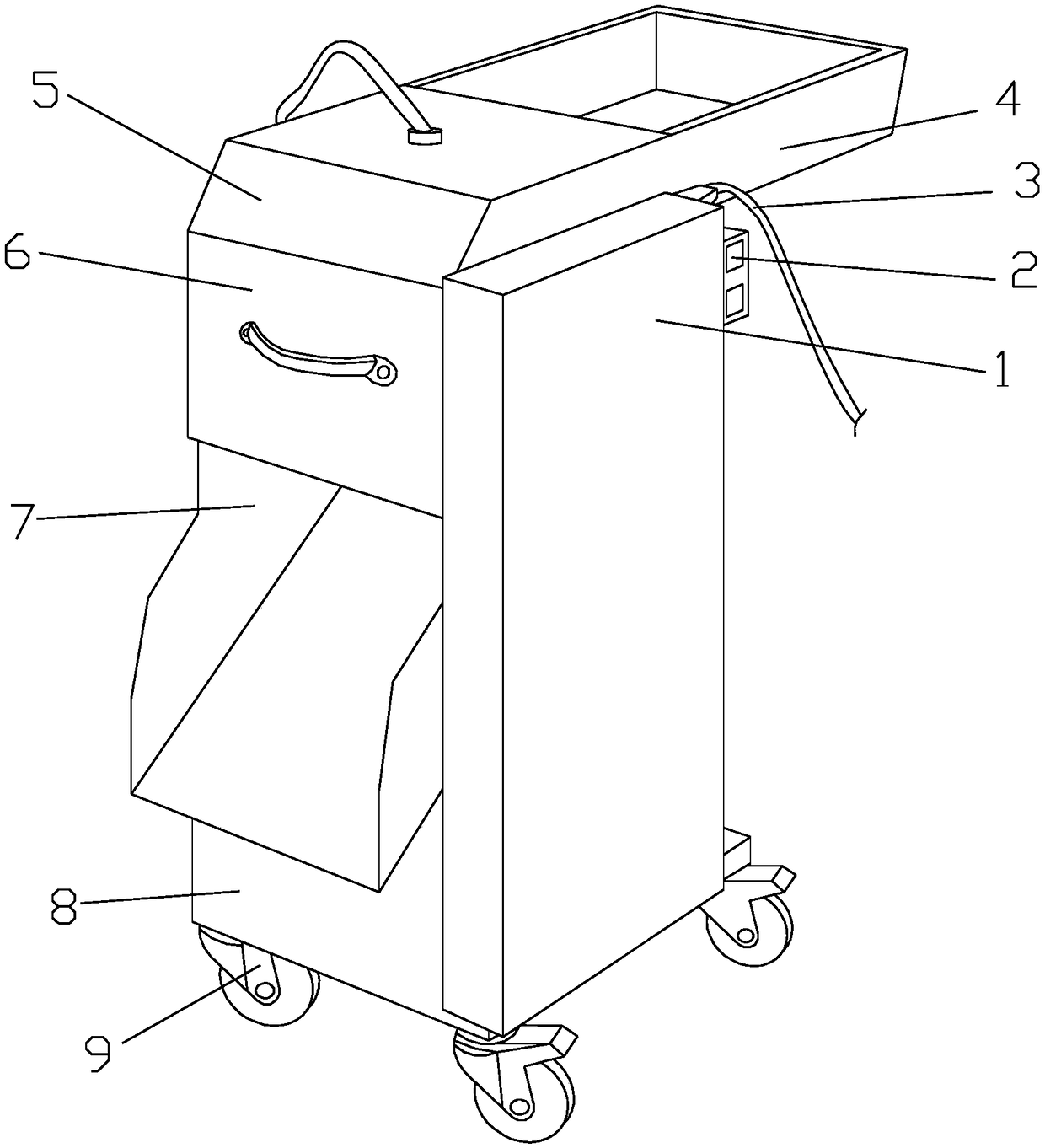

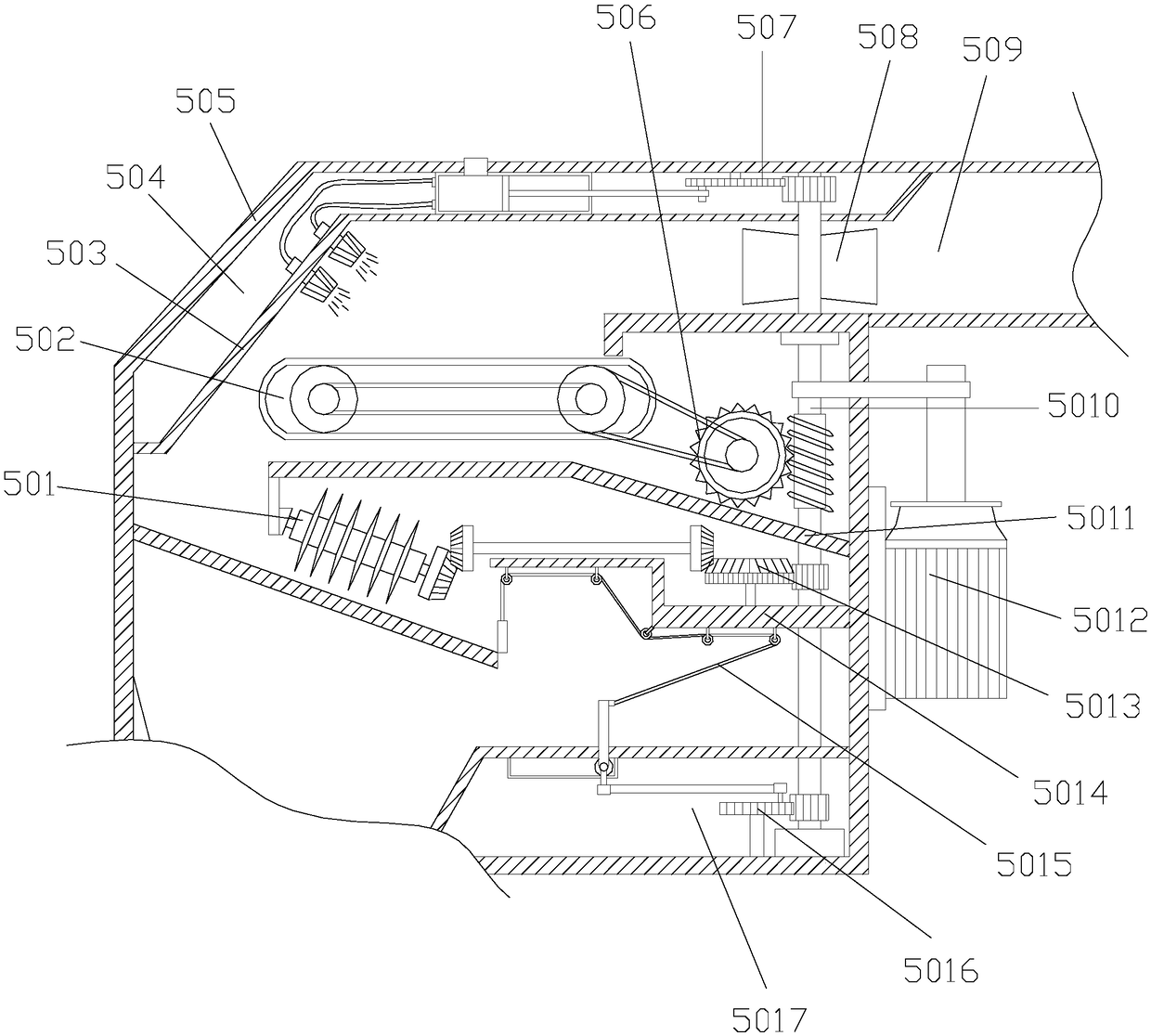

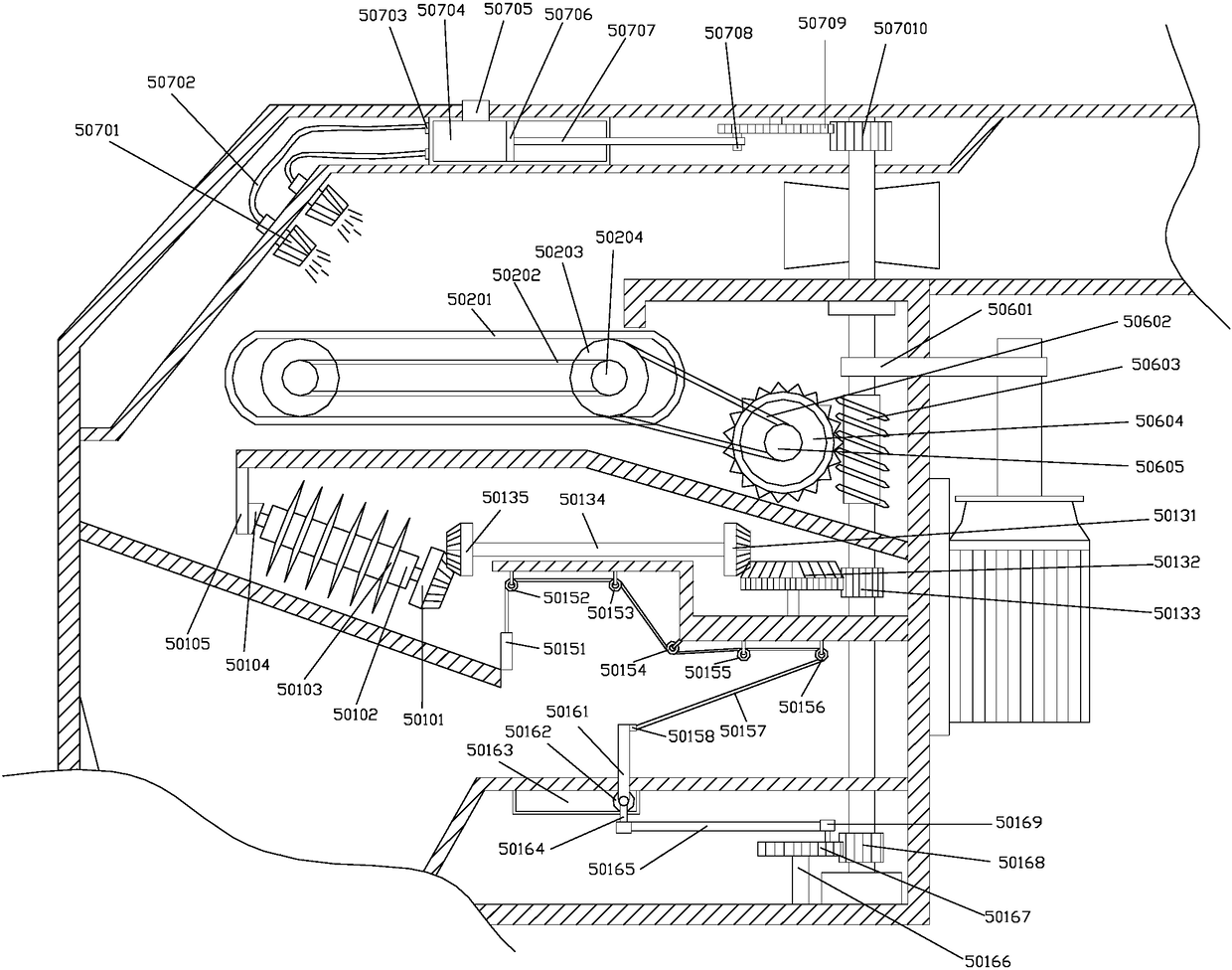

[0028] see Figure 1-Figure 8 , the invention provides a kind of novel squid slice flower cutting equipment: its structure comprises fixed vertical arm 1, switch button 2, power cord 3, feed hopper 4, processing box 5, protective cover 6, discharge hopper 7, main frame 8, Universal wheels 9, four universal wheels 9 are installed on the four corners of the bottom of the main engine 8 by buckling, and the right side of the main engine 8 is provided with a fixed vertical arm 1 and connected by buckling. Both sides of the processing box 5 are installed on the top of the main machine 8 by embedding, the front end of the processing box 5 is provided with a rectangular groove for movable installation of the protective cover 6, and the front end of the feeding hopper 4 is connected to the rear of the processing box 5. The ends are connected and formed as an integral structure. The top of the discharge hopper 7 is installed on the lower end of the processing box 5 by buckling, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com