Surface paint sprayer capable of preventing oxidation of filter

An anti-oxidation and paint sprayer technology, applied in the field of paint sprayers, can solve problems such as difficulty in spraying filters, physical effects, and paint pollution to the air, and achieve the effect of ensuring air and enhancing functionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

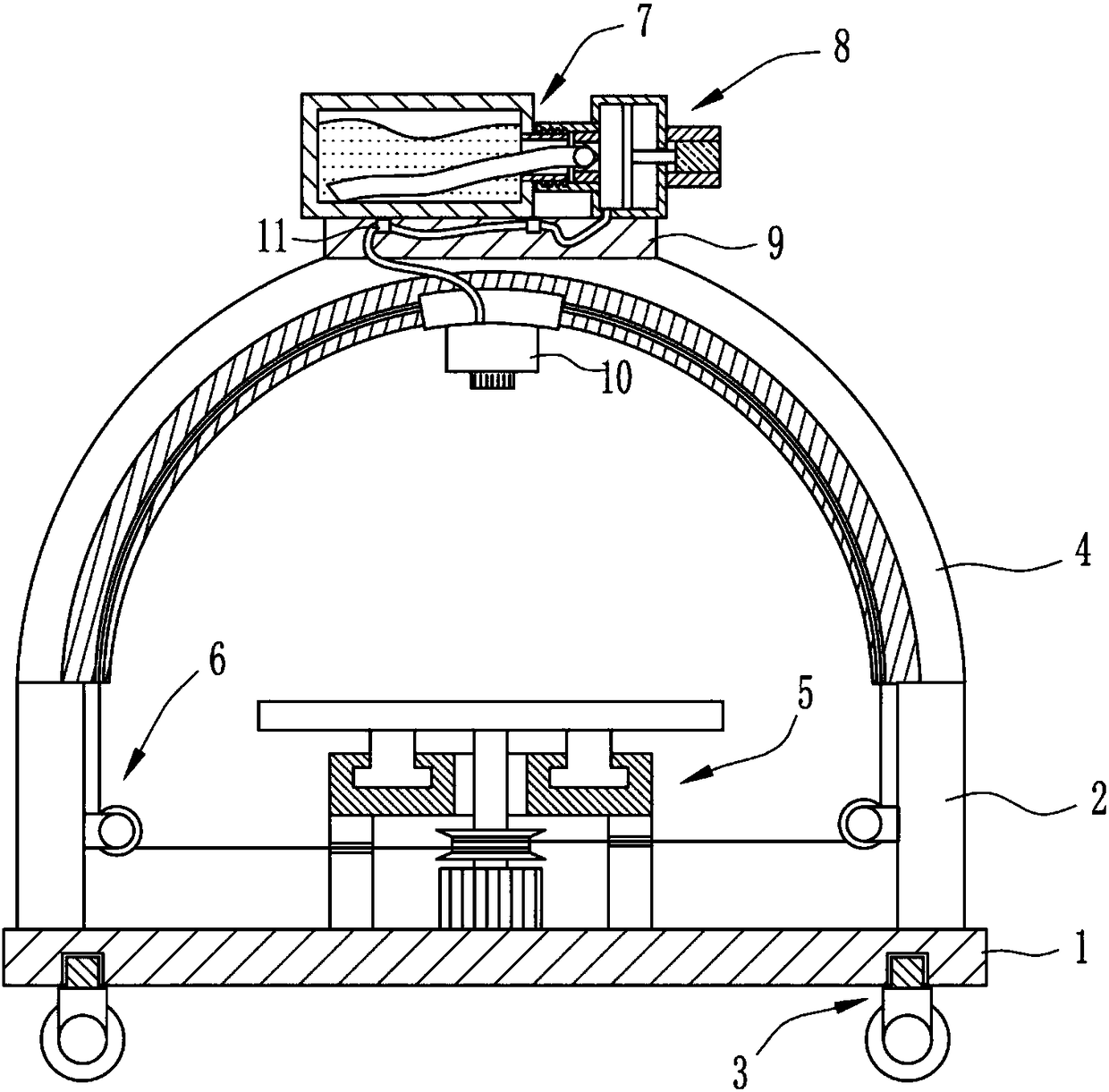

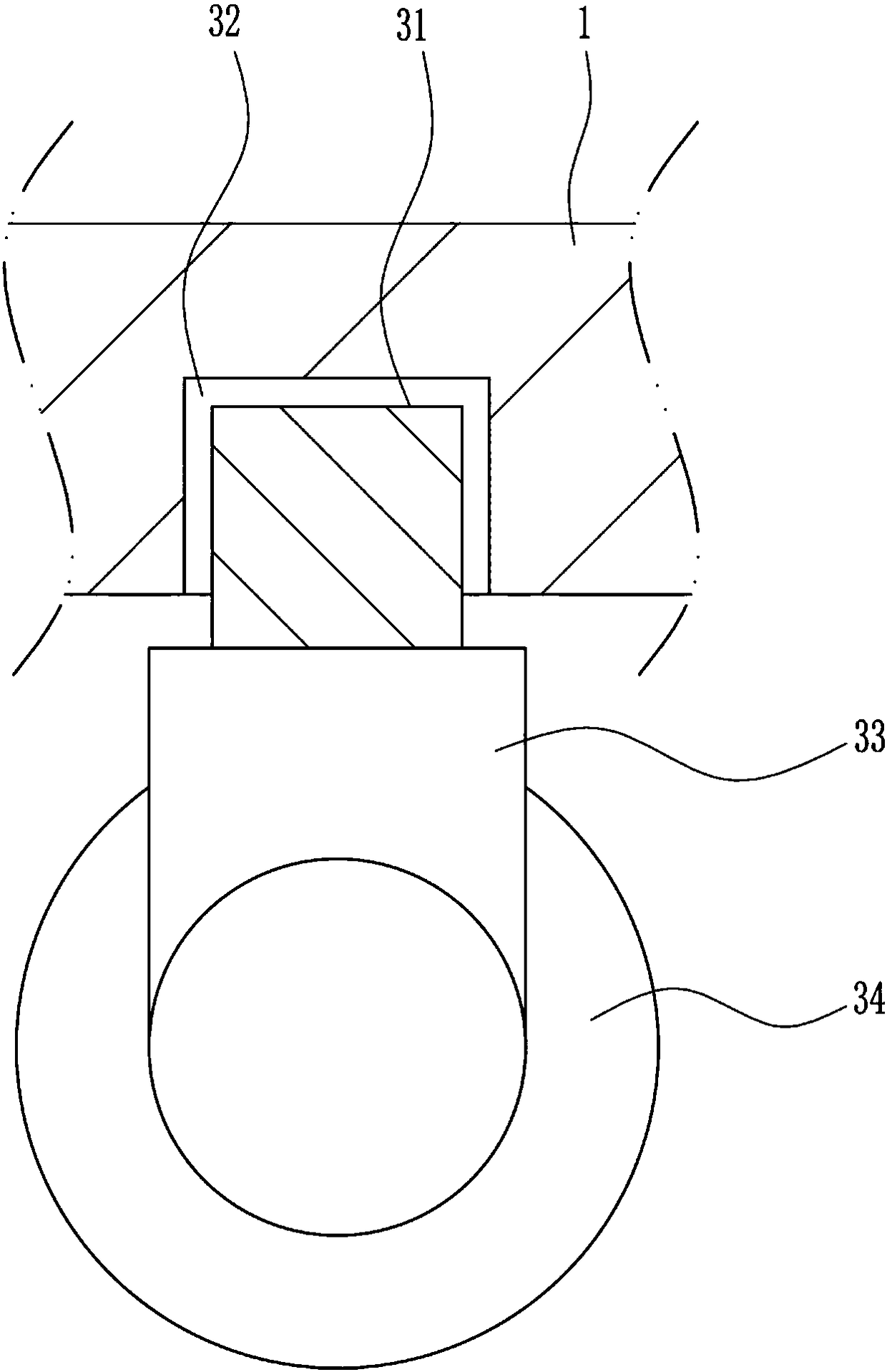

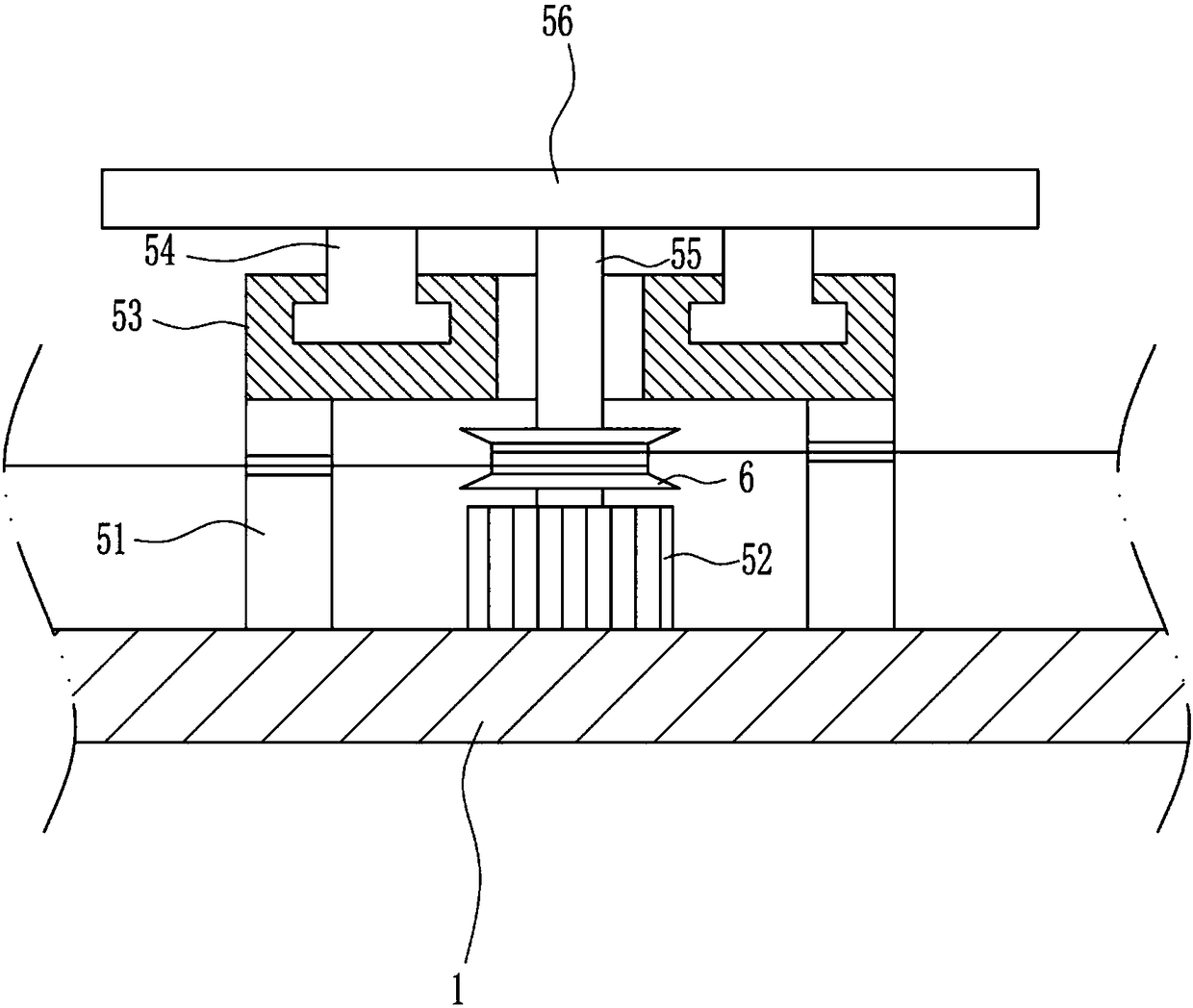

[0036] A surface spraying machine for anti-oxidation of filters, such as Figure 1-8 As shown, it includes a mounting plate 1, a bearing plate 2, a moving part 3, a curved plate 4, a rotating part 5, a stretching part 6, a storage part 7, a spraying part 8, a fixed plate 9, a nozzle 10 and a buckle 11 The bearing plate 2 and the rotating part 5 are fixedly connected to the top of the mounting plate 1 in turn, and the rotating part 5 is located in the middle of the bearing plate 2; the moving part 3 is screwed to the bottom surface of the mounting plate 1; The stretching part 6 is fixedly connected to the curved plate 4, and is connected to the output end of the rotating part 5; the nozzle 10 is slidingly connected to the output end of the stretching part 6; Connected to the top surface of the fixing plate 9, the material storage part 7 is screwed to the spraying part 8; the buckle 11 is fixedly connected to the front side of the fixing plate 9, and the spraying part 8 bypasses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com