Automobile model raw material production device

A technology for making devices and car models, applied in the field of equipment for obtaining or processing clay, can solve problems such as material waste, and achieve the effect of avoiding waste and avoiding excessive length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

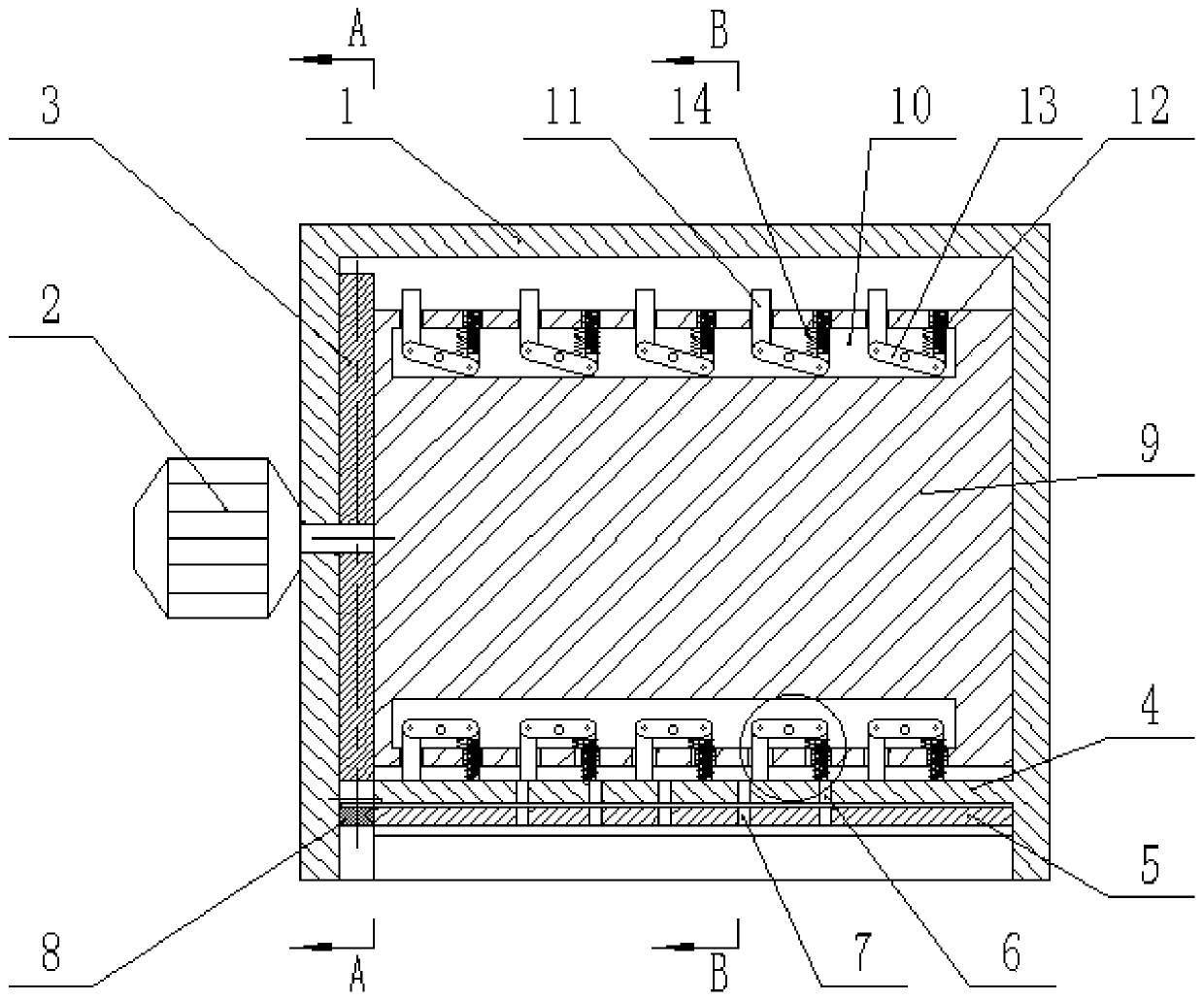

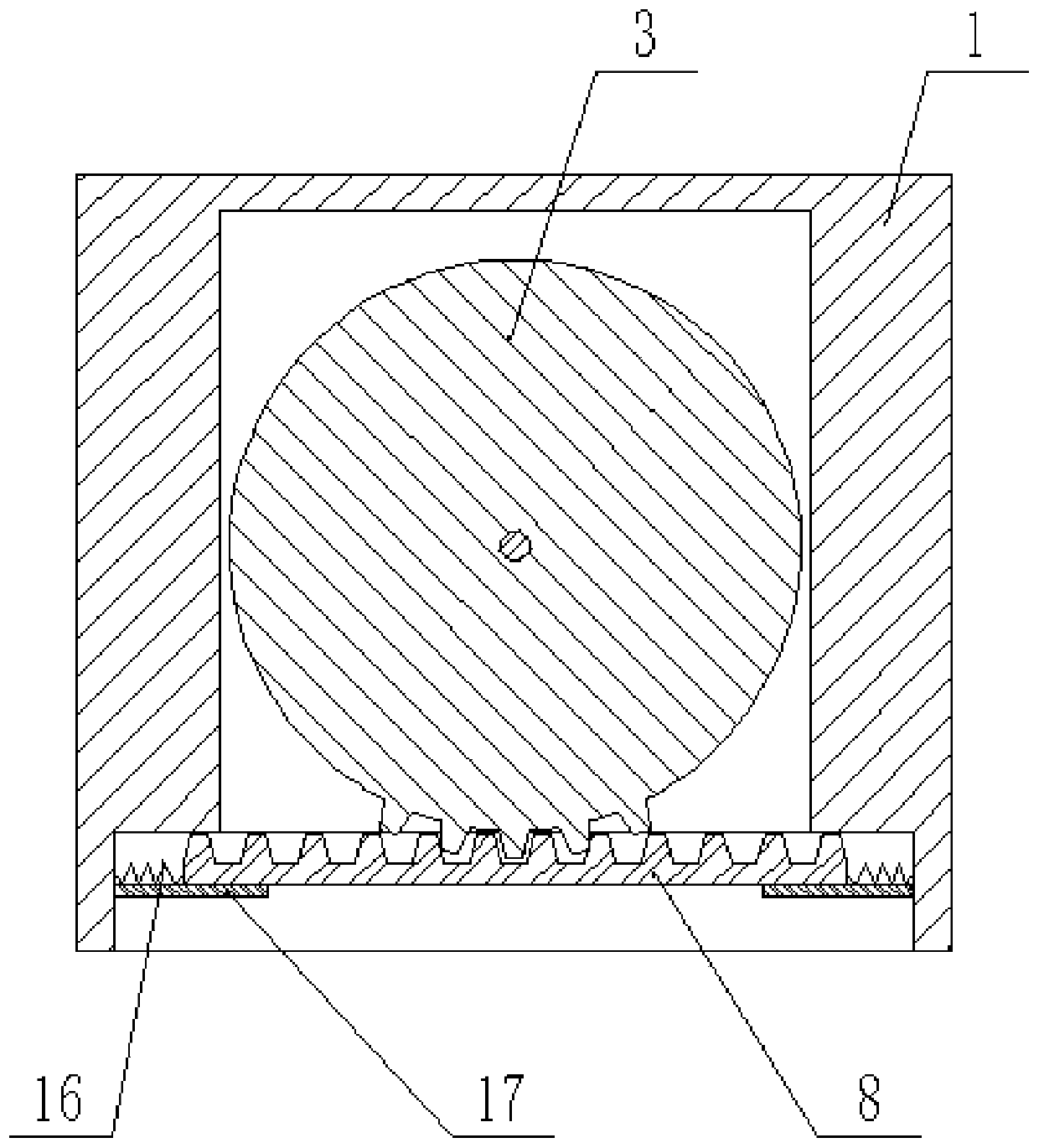

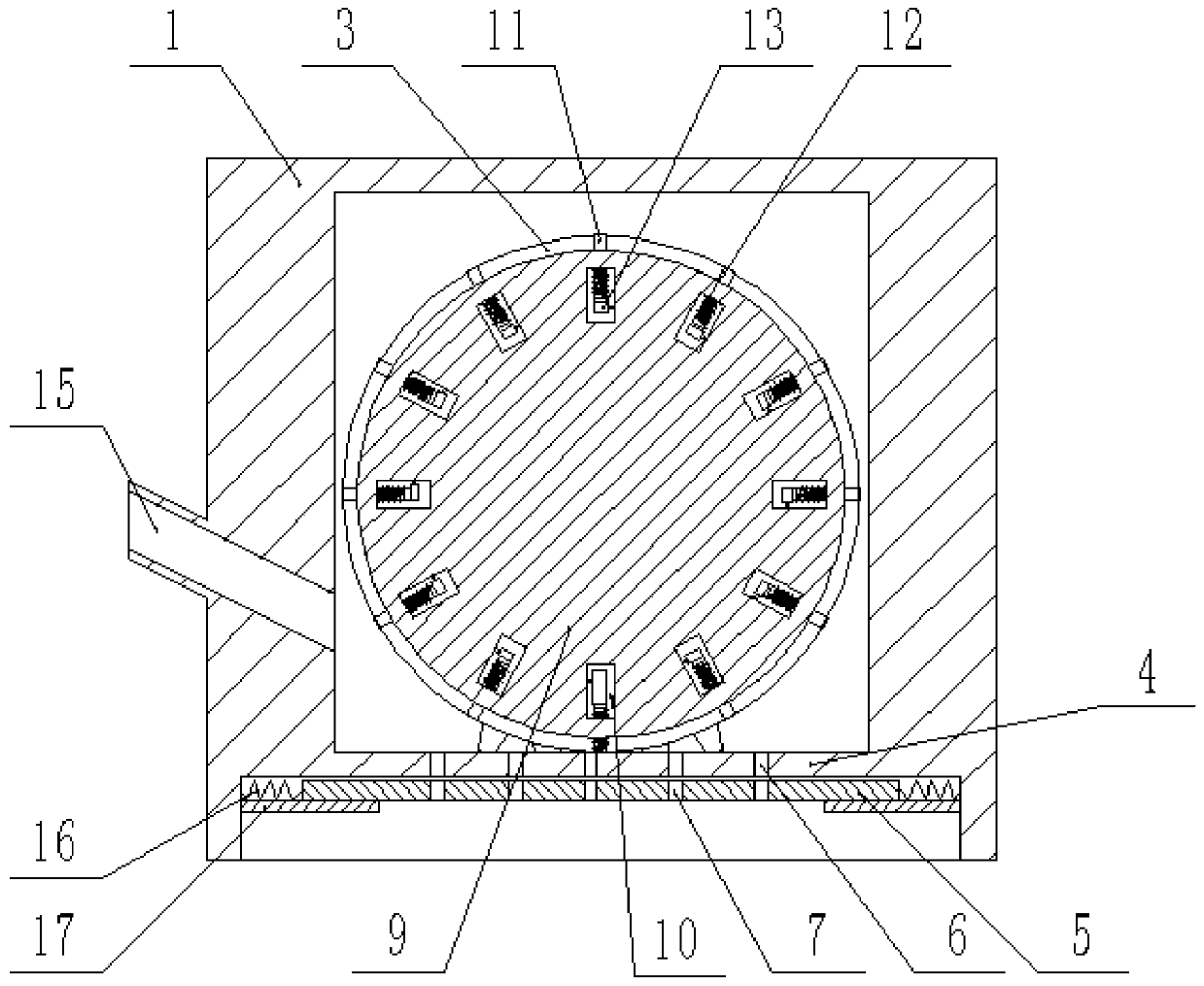

[0022] The following is further described in detail through specific implementation methods:

[0023] The reference signs in the drawings of the description include: box body 1, motor 2, drive gear 3, extrusion plate 4, shear plate 5, extrusion through hole 6, shear through hole 7, rack 8, extrusion roller 9. Cavity 10, pressure rod 11, threaded sleeve 12, connecting rod 13, pressure spring 14, feed inlet 15, spring 16, positioning boss 17, positioning rod 18, positioning pin 19, spiral groove 20, spiral Blade 21.

[0024] The embodiment is basically as figure 1 , figure 2 , image 3 with Figure 4 Shown: a car model raw material production device, including a box body 1, the upper inner wall of the box body 1 is fixedly installed with a heating wire, and the inner wall on the left side of the box body 1 is rotatably installed with a driving gear 3, and the driving gear 3 is an incomplete gear , the motor 2 is fixedly installed on the left side wall of the box body 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com