High-rigidity two-plate die locking mechanism

A high-rigidity and clamping technology, applied in the field of two-plate high-rigidity clamping mechanism, can solve the problems of insufficient clamping rigidity and complex control technology, and achieve the effects of low cost, simple technology and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

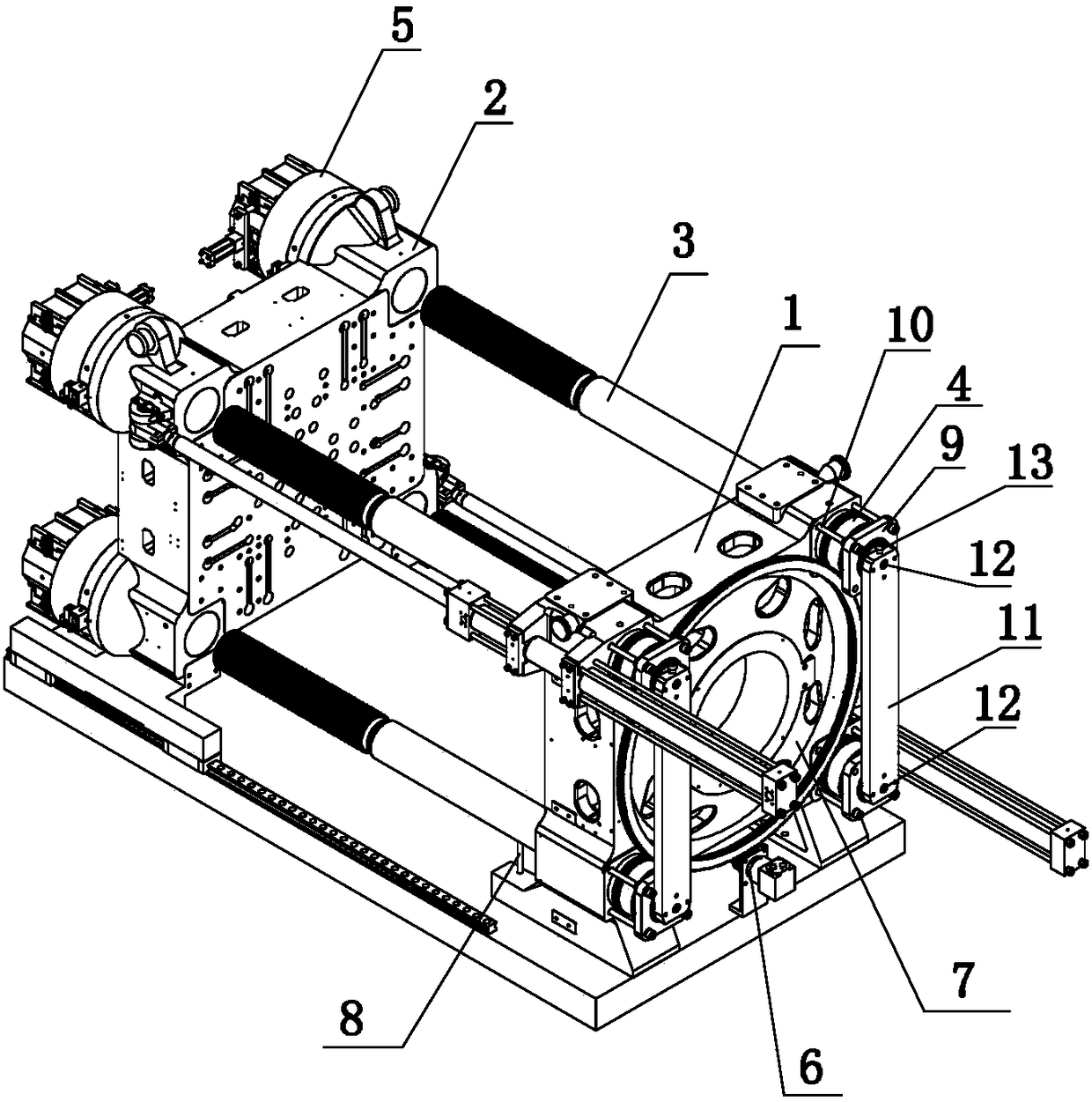

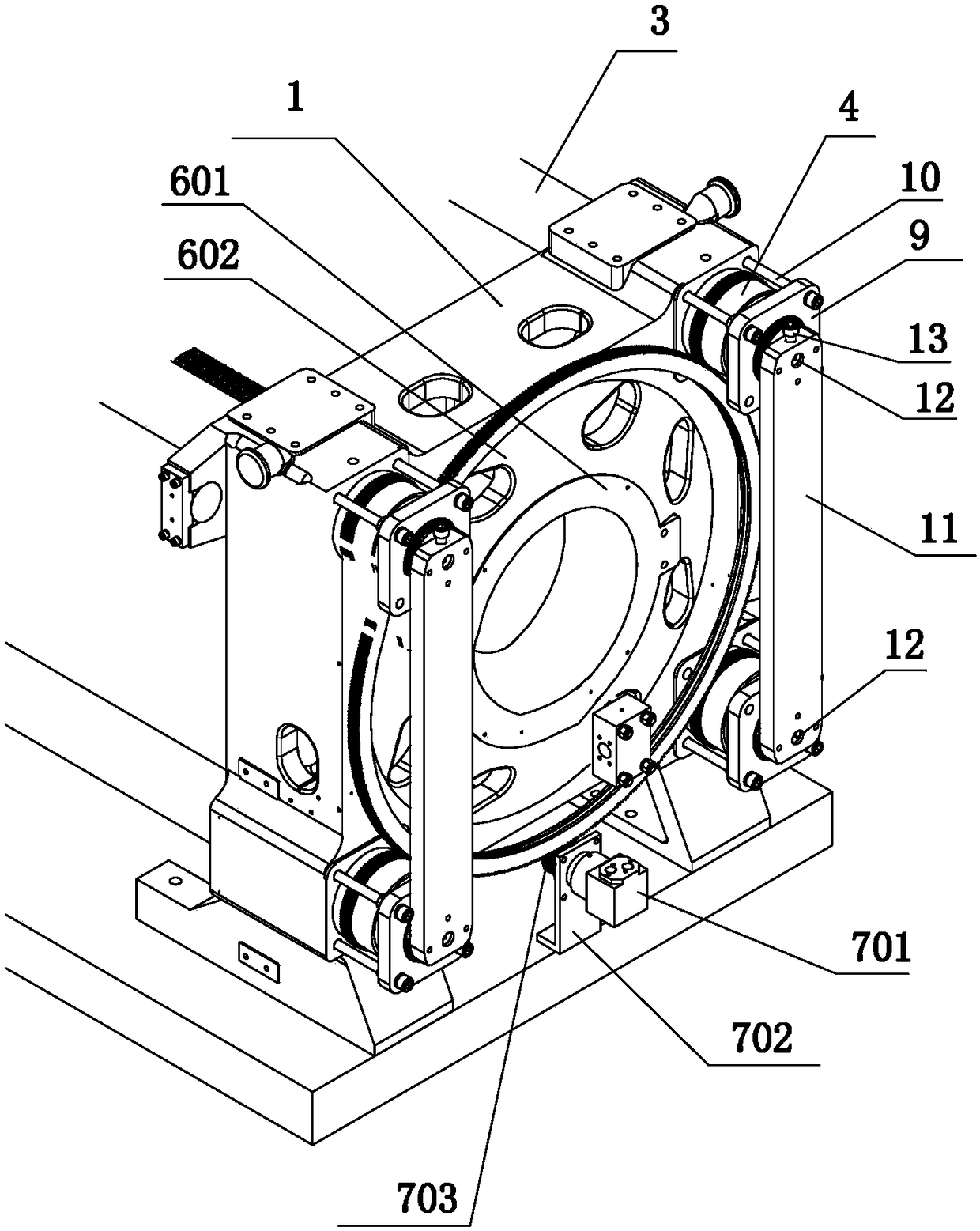

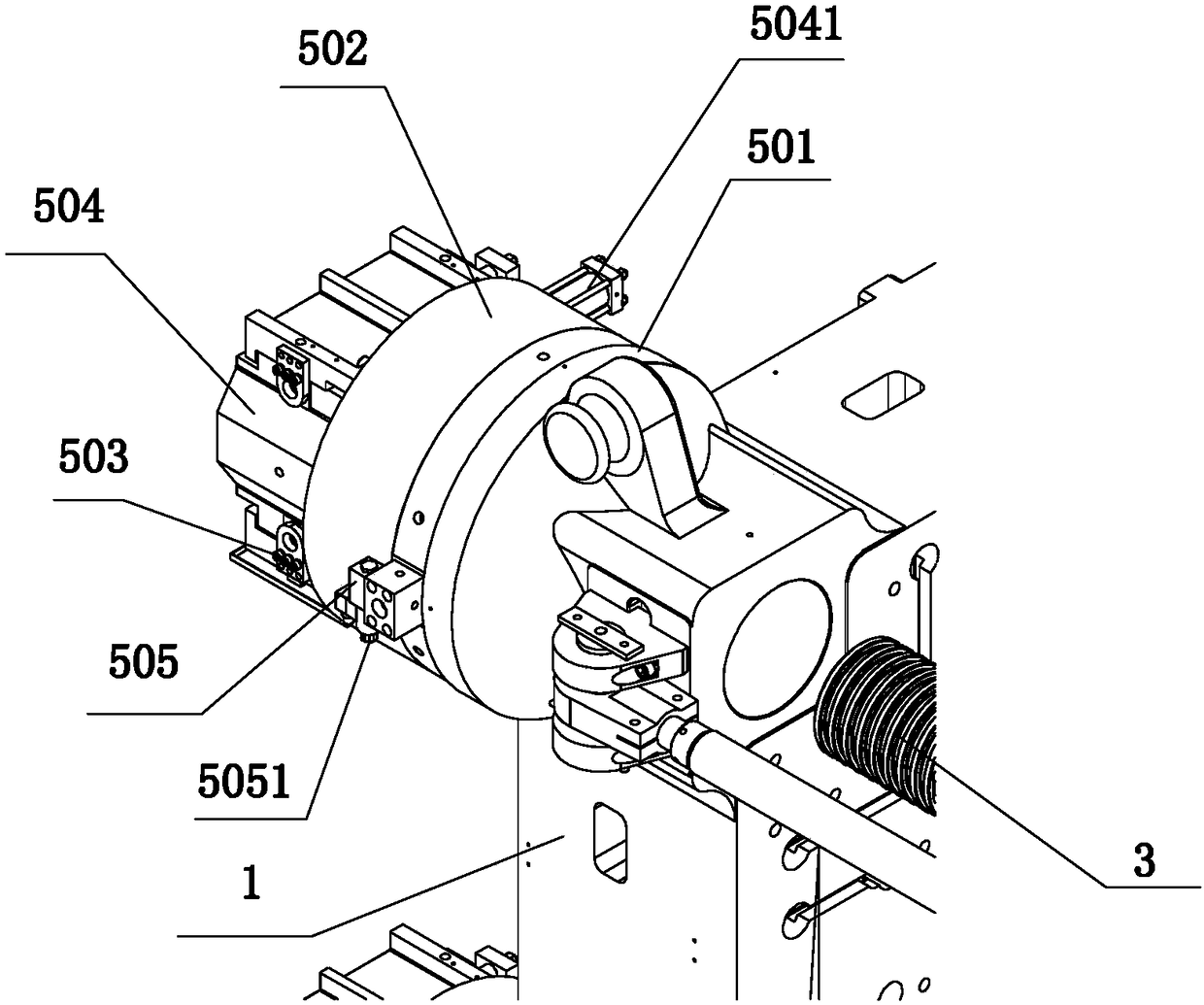

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] refer to Figure 1-4 :

[0028] A high-rigidity mold clamping mechanism includes a fixed template 1, a movable template 2 and four tie rods 3.

[0029] The fixed ends of the four pull rods 3 pass through the four through holes provided at the four corners of the fixed template 1 respectively, and are respectively screwed with the four pull rod nuts 4 to be connected to the fixed template 1 .

[0030] The outer sides of the four pull rod nuts 4 are provided with nut glands 9, and the nut glands 9 are socketed on the corresponding pull rods 3 through the through holes provided on the cover body, and fixed by the connecting rod 10. Installed on the outer end face of the fixed formwork 1.

[0031] The outside of the fixed template 1 is provided with a transmission mechanism 6, the transmission mechanism 6 includes a fixed shaft 601 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com