Electrocauterization pen special for pyrograph

An electrocautery pen and pyrograph technology, which is applied to the field of painting art creation tools, can solve the problems of troublesome operation, poor grip of the electrocautery pen, unfavorable for painters to paint, etc., so as to reduce the replacement of iron core rods and enhance the hand grip. Sensation, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

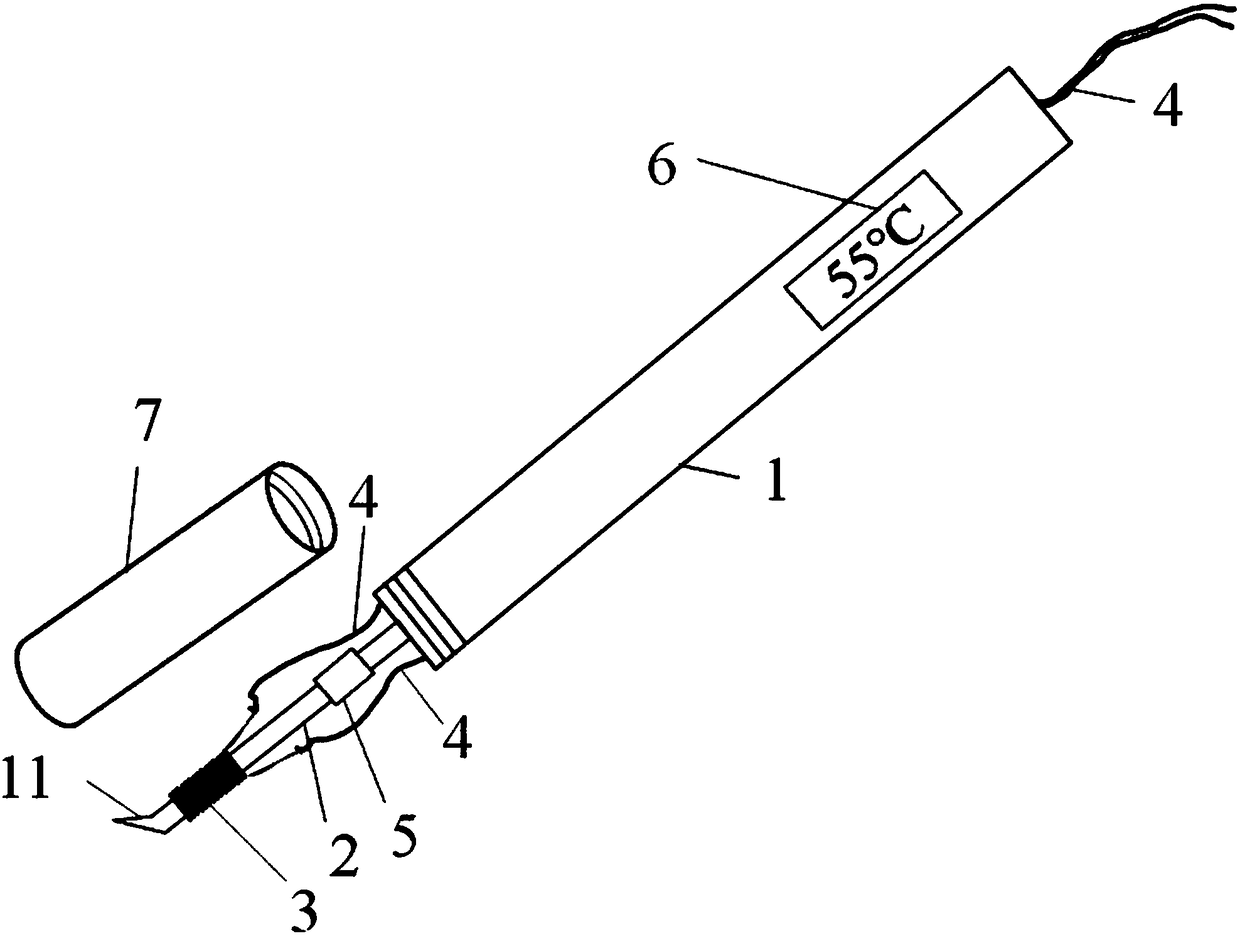

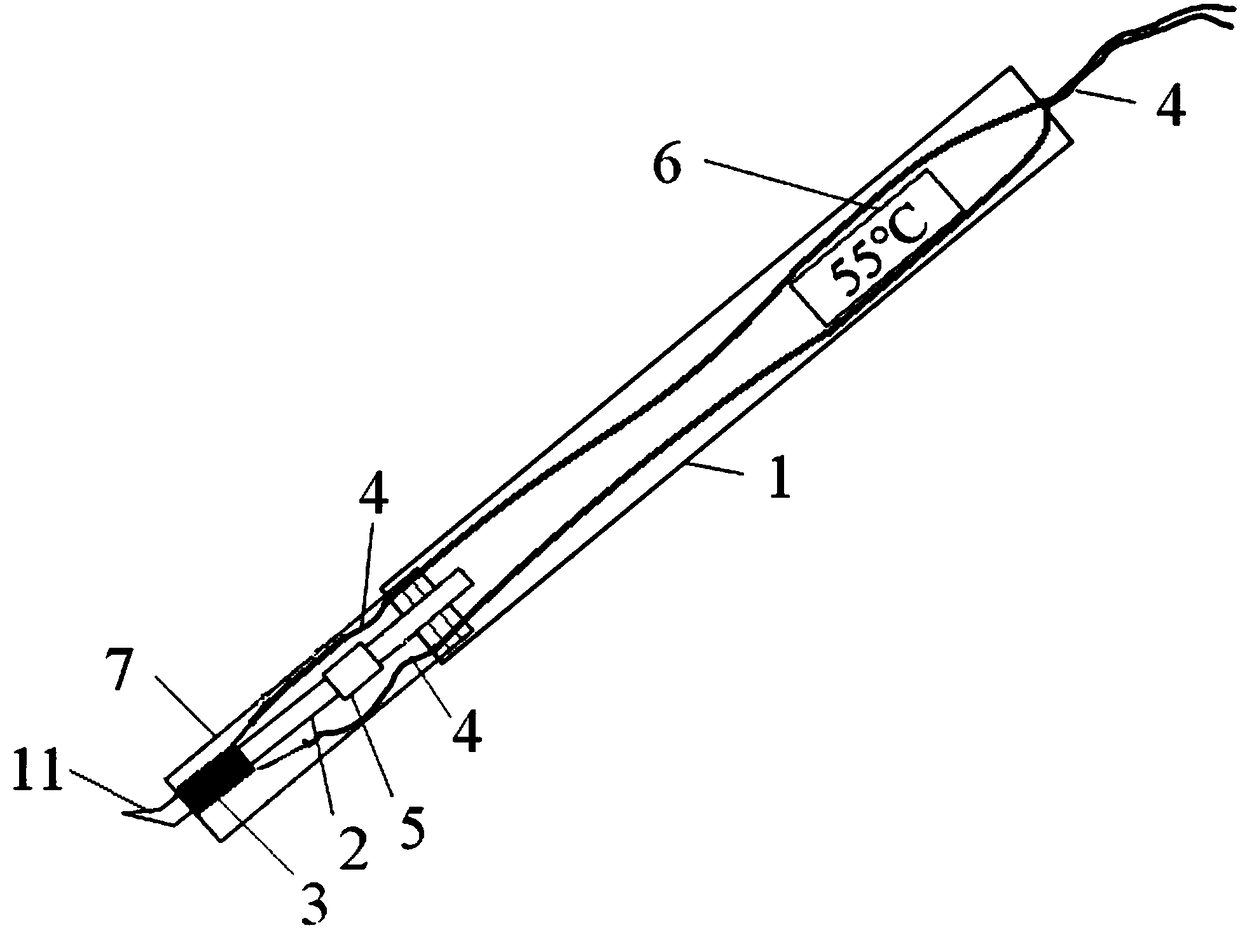

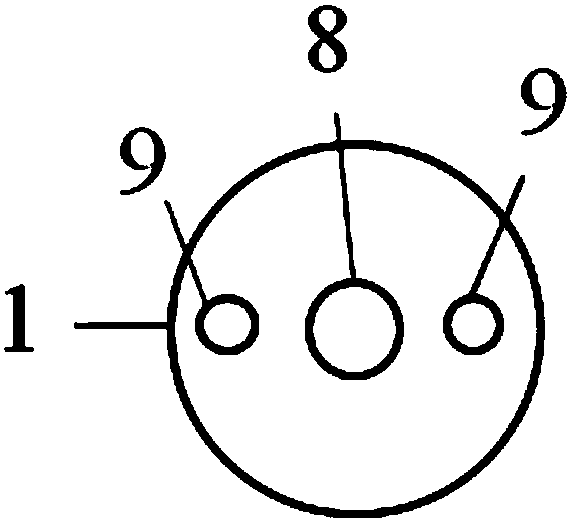

[0025] Such as figure 1 and 2 The schematic diagram of the special electric ironing pen for pyrography shown, the special electric ironing pen for pyrography includes a pen cover 1, the front end of the pen cover 1 is connected with a protective cover 7, preferably, the pen cover 1 and the protective cover 7 are both belts Cylindrical with internal space. The connection methods of the pen case 1 and the protective case 7 include but not limited to welding, pins, threads, etc. Preferably, the pen case 1 and the protective case 7 are connected by threads. The connection between the pen cover 1 and the protective cover 7 is respectively provided with internal and external threads or external and internal threads, that is, the front inner wall of the pen cover 1 is provided with internal threads, and the rear end outer wall of the protective cover 7 is provided with external threads. , by screwing the protective cover 7 into the inner wall of the pen cover 1 to connect the two (...

Embodiment 2

[0030] Such as Figure 5 As shown, the difference between the second embodiment provided by the present invention and the first embodiment lies in the front end of the pen cap 1, the special electric ironing pen in the second embodiment does not have a protective cover 7, but the length of the pen cap 1 is longer than that of the first embodiment. One of the lengths is long, so that one end of the iron core rod 2, the electric furnace wire 3 and the electric wire 4 connected to the electric furnace wire 3 can be included in its internal space, and only the nib 11 of the iron core rod 2 is exposed. That is, the pen tip 11 is located outside the pen case 1, and other structures in the second embodiment are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com