Rail train platform expansion footboard device

A technology of telescopic pedals and rail trains, applied in stations, tracks, roads, etc., can solve problems such as loss and inability to retrieve, and achieve the effect of avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

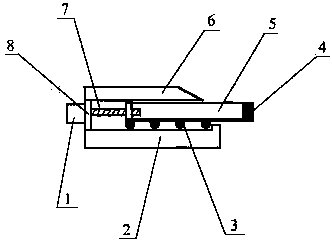

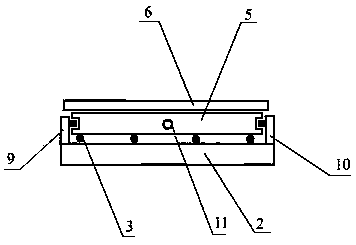

[0018] The rail train platform telescopic pedal device provided by the present invention includes a base plate 2, a bearing 3, a shrinking plate 5, a cover plate 6, a drive motor 1, an outer threaded pull rod 7, and an elastic strip 4; Two chutes perpendicular to the side of the platform, each chute has at least two bearings 3, the bearings 3 are fixedly connected to the shrinking plate 5 through the concave crankshaft 14, and the elastic strip 4 is fixedly arranged in front of the expansion plate 5, When described telescopic plate 5 stretches out, elastic strip 4 contacts with the lower edge of train box door; The wall 10 is fixedly connected to the rear wall 8, and the left wall 9, the right wall 10 and the rear wall 8 are respectively fixedly connected to the left side, the right side and the rear edge of the base plate 2; the inner surfaces of the left wall 9 and the right wall 10 are respectively provided with slide bars 12, The left side and the right side of the shrinki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com