Labor-saving garbage truck for environmental sanitation

A garbage truck and sanitation technology, which is applied in the field of labor-saving garbage trucks for sanitation workers, can solve the problems of inconvenient cleaning, re-pollution, troublesome operation, etc., and achieve the effects of simple and fast operation, avoiding secondary pollution, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

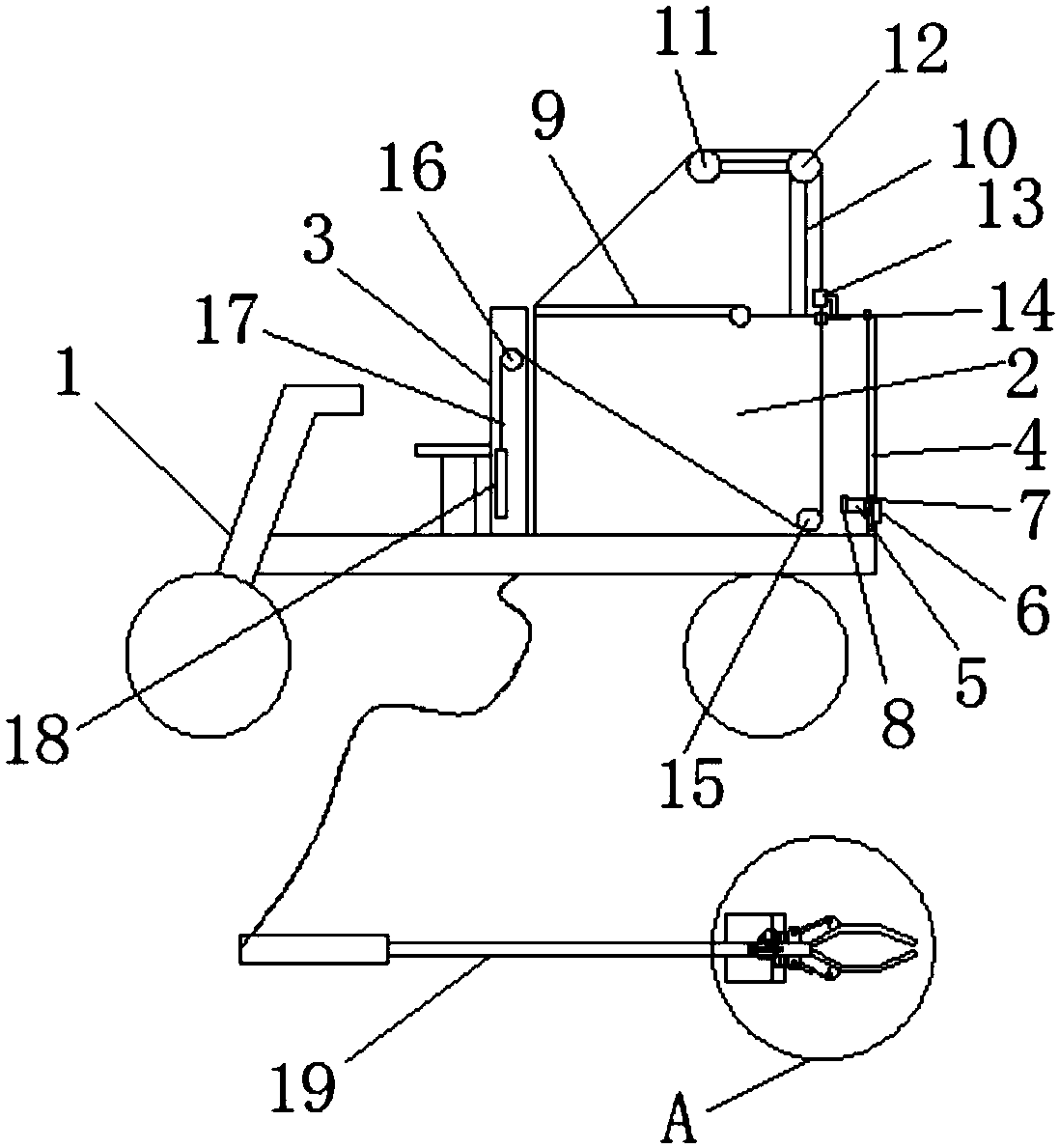

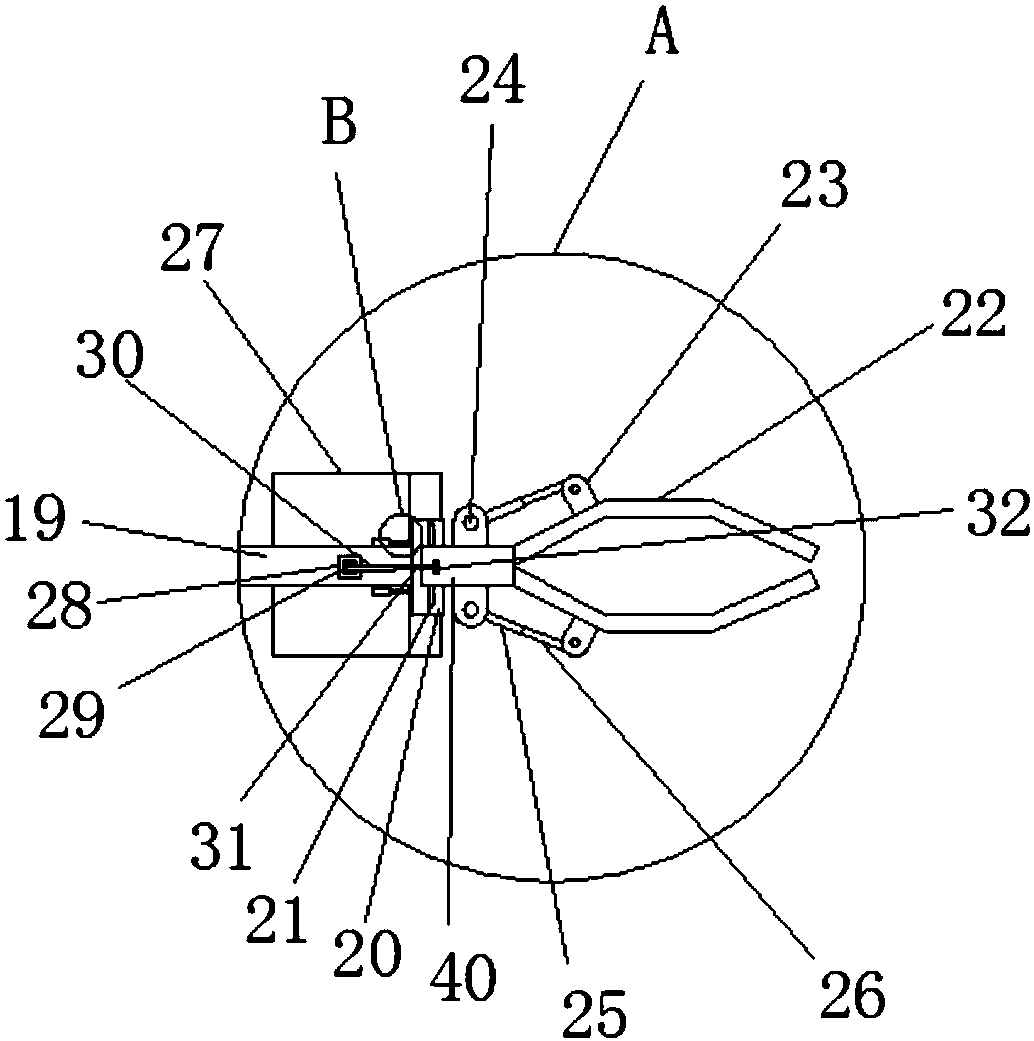

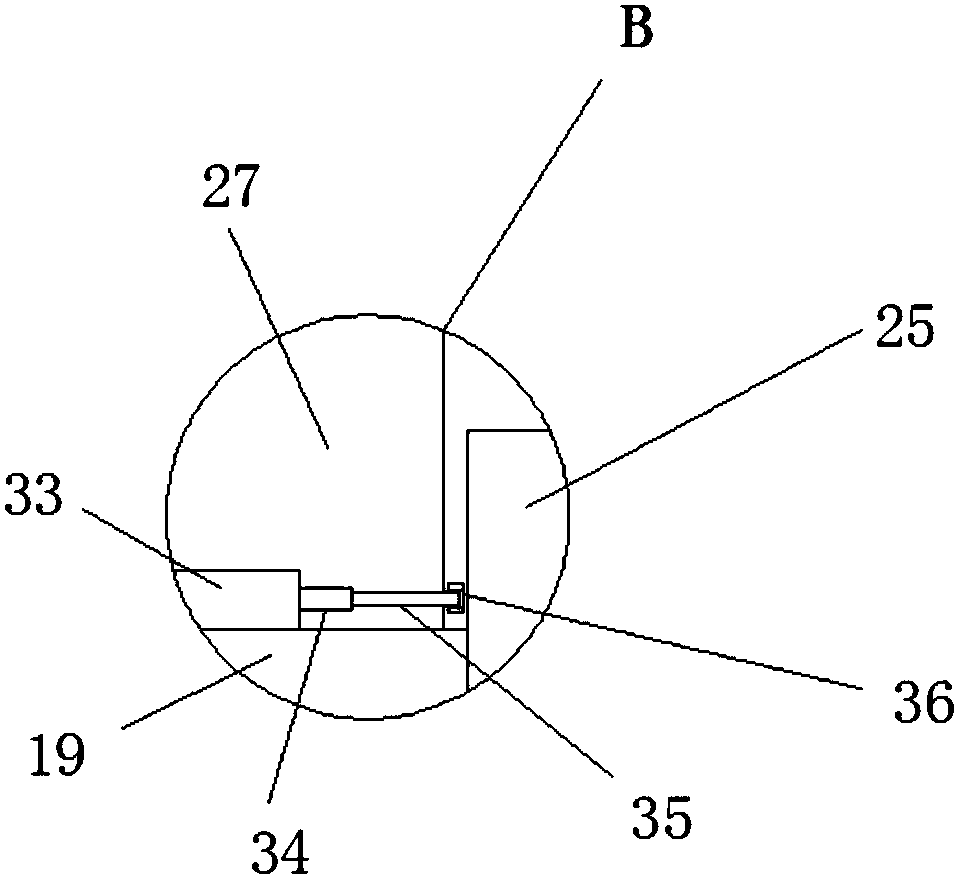

[0023] refer to Figure 1-5 , a labor-saving garbage truck for sanitation workers, comprising a battery car 1, a garbage bin 2, a clamp bar 19, a first hydraulic cylinder 25, a second hydraulic cylinder 30 and a third hydraulic cylinder 34, and a garbage bin is installed on the top of the battery car 1 2. A backrest 3 is installed on the left side of the dustbin 2, and a first lid 4 is hinged on the right end of the dustbin 2, which can clean up the full garbage, and the dustbin 2 can be cleaned through the first lid. Sleeves 5 are installed on the front and rear side walls of the first box cover 4, and hanging buckles 7 are installed on the front and rear side walls of the first box cover 4. A movable pin 6 is inserted at the right end of the sleeve pipe 5, and the left end of the movable pin 6 runs through Sleeve 5 is connected with limit block 8, the right end of the movable pin 6 is articulated with the hook 7, and the first case cover 4 is closed and fastened by the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com