Image-text paper feeder

A paper feeder and graphic technology, applied in the field of graphic equipment, can solve the problems of cost, low efficiency, and large manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

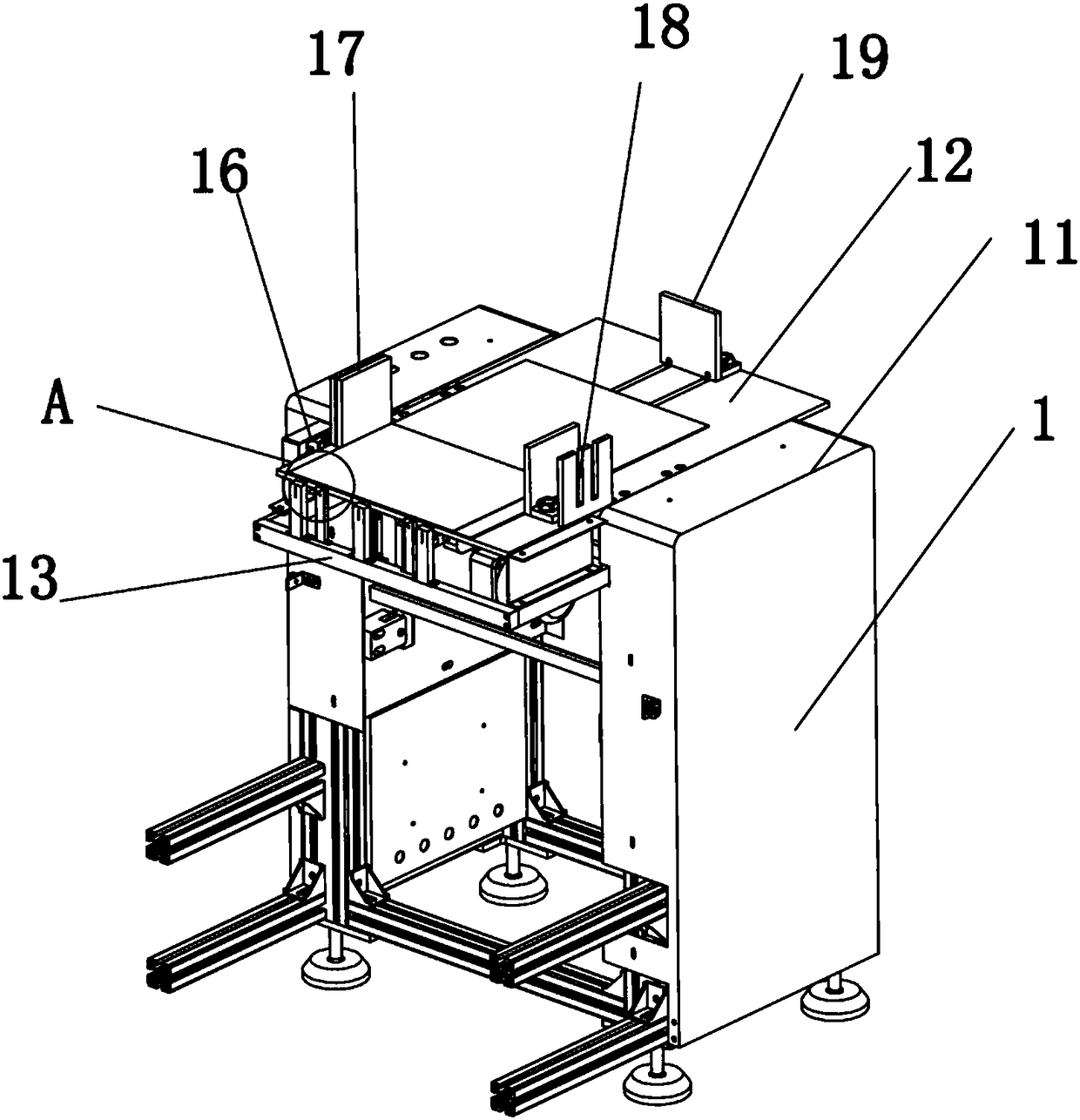

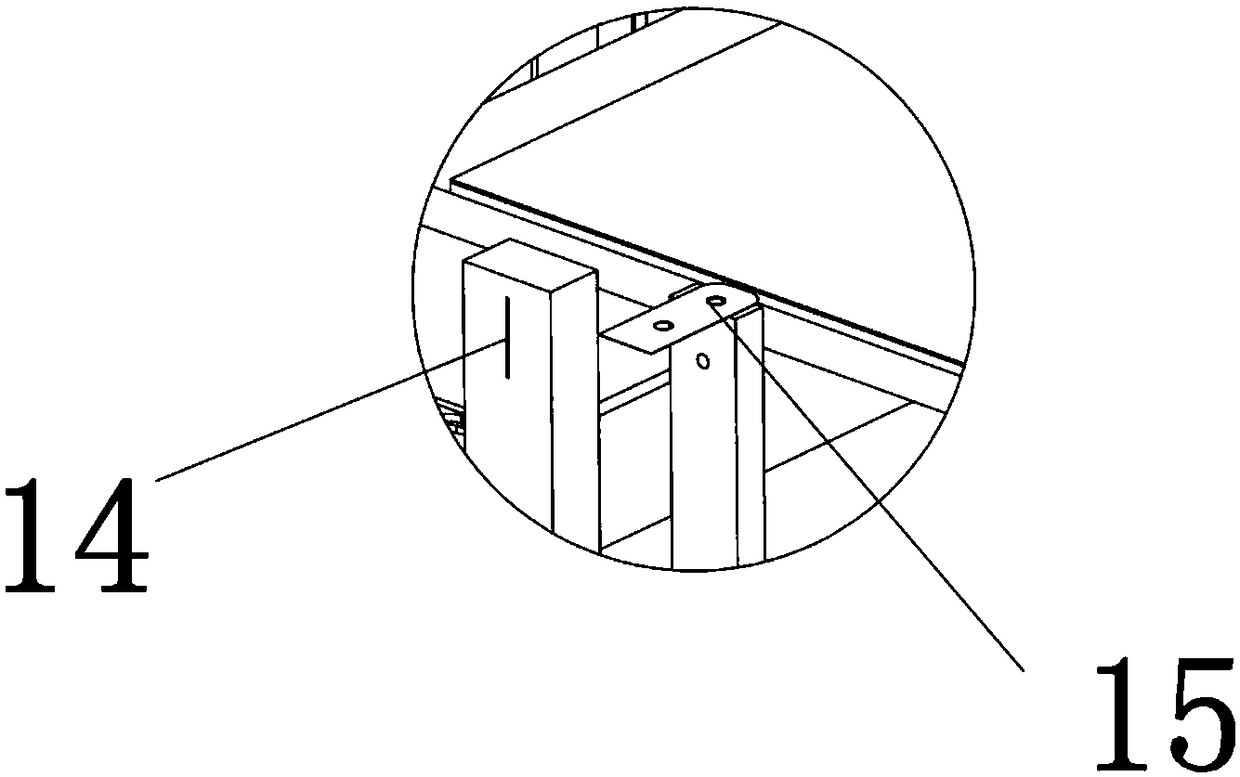

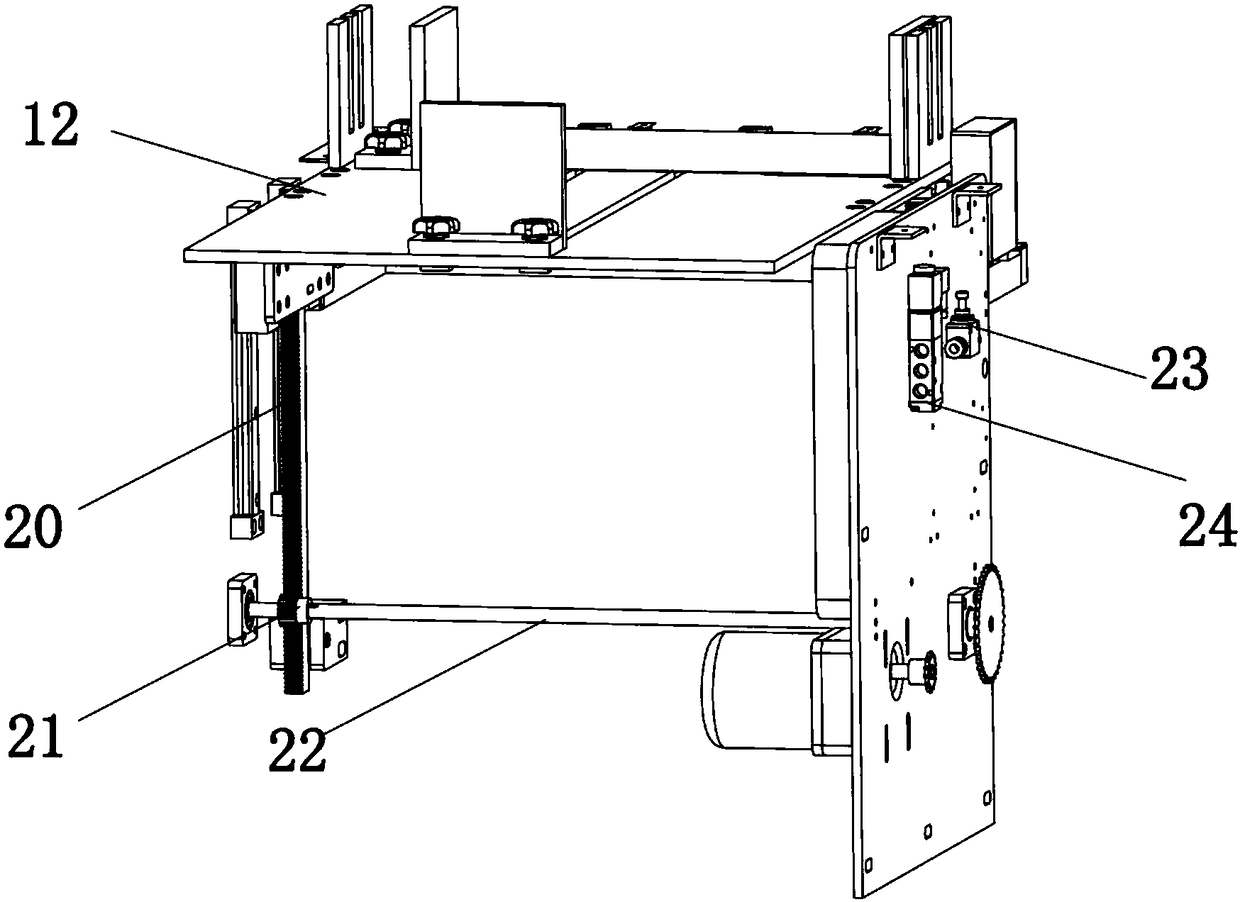

[0016] Such as Figure 1-3 As shown, a graphic paper feeder includes a main body 1 of the paper feeder and a liftable suction cup, the suction cup is used to absorb paper on the main body 1 of the paper feeder, and the main body 1 of the paper feeder includes a frame 11 , the frame 11 is provided with a base plate 12 that can be lifted up and down, and a support 13 is provided on the side of the frame 11. The support 13 is provided with an air blowing device 14 that can separate paper and a pillar with an elastic pressure plate 15 at the top , the side of the bracket 13 is provided with two inductors 16, which are respectively a first inductor and a second inductor, wherein the height of the first inductor is lower than the height of the second inductor;

[0017] The two sides of described base plate 12 are provided with slidable side baffle plate 17 and non-slidable fixed plate 18, and the end of described base plate 12 is provided with slidable positioning plate 19, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap