Washing machine with replaceable inner tub

A technology for washing machines and inner tubs, applied in the field of washing machines with replaceable inner tubs, which can solve problems such as cross-infection and secondary pollution, and achieve healthy and hygienic operations, reliable principles, and good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

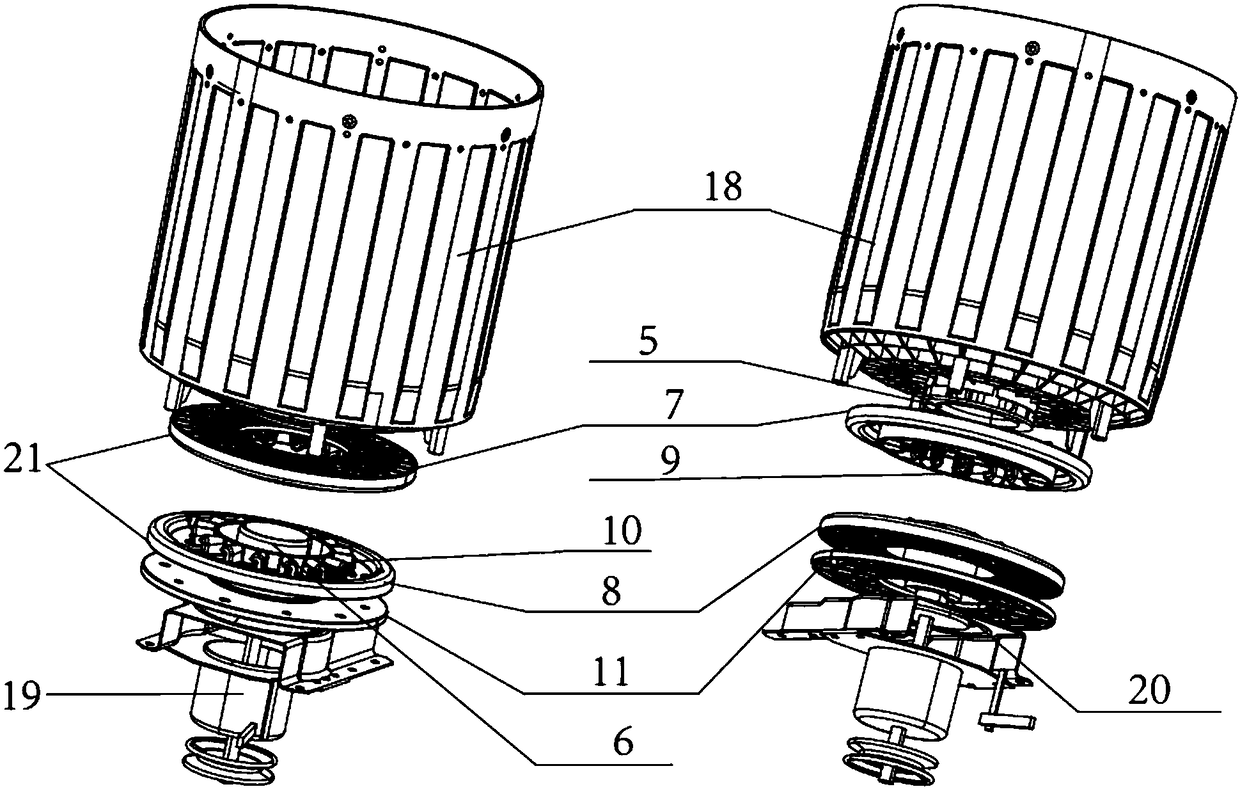

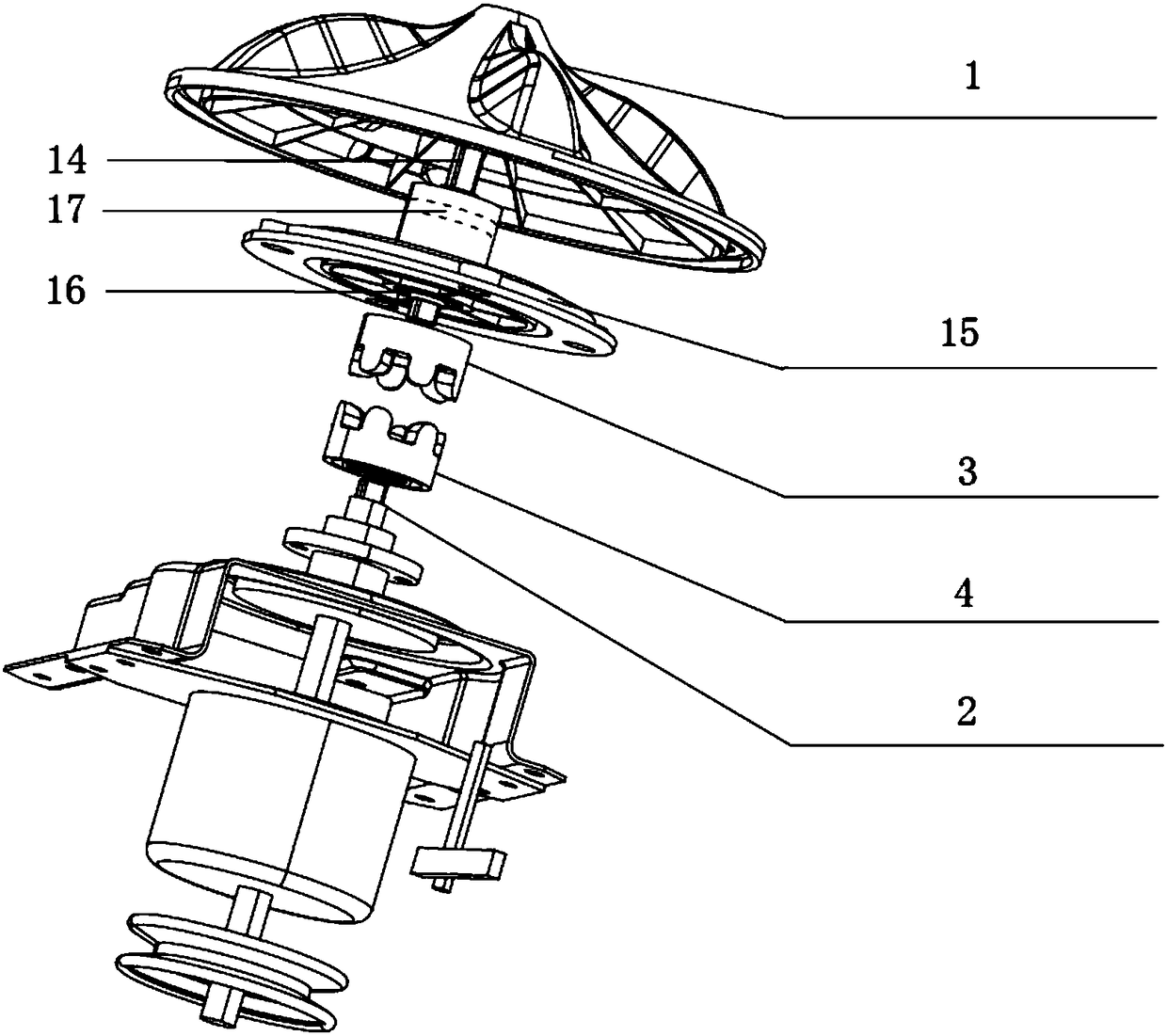

[0022] The main structure of the pulsator washing machine with replaceable inner tub 18 involved in this embodiment is as follows: figure 1 Shown includes the inner tub 18, the clutch 19, the transmission mechanism 21 that can be disassembled quickly between the inner tub 18 and the clutch 19, in order to reduce the radial or axial runout caused by centrifugal action when the inner tub 18 rotates, and improve the inner tub 18 when rotating. The stability of the transmission mechanism 21 is a disc-shaped or wheel-shaped structure, and the transmission coordination point is set at a place far away from the axis of the inner barrel 18 to increase the transmission force arm.

Embodiment 2

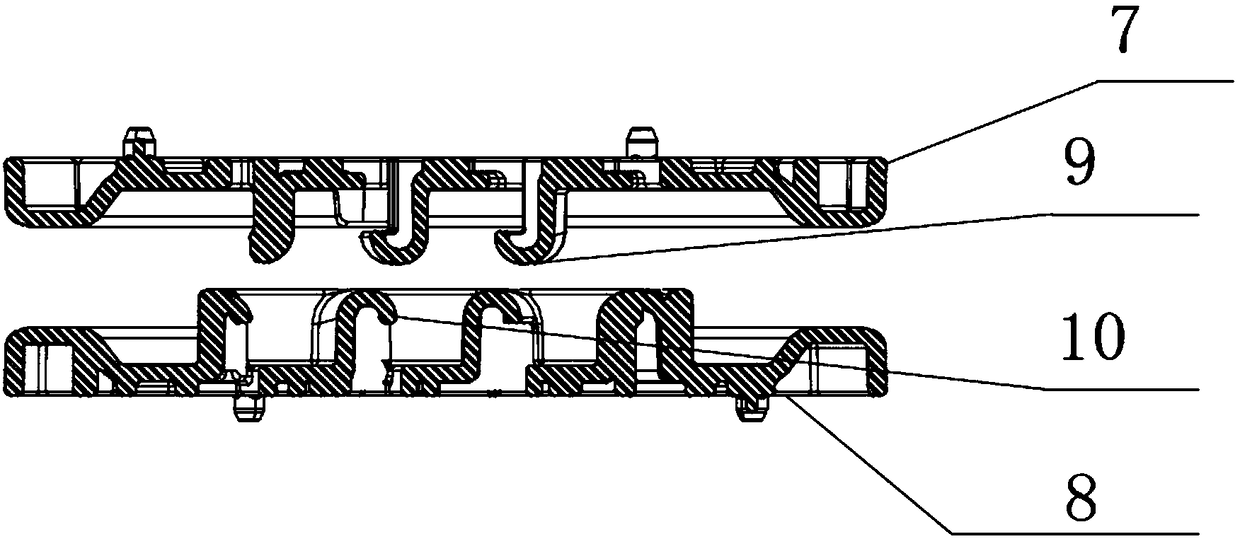

[0024] The difference between this embodiment and Embodiment 1 is that the transmission mechanism 21 includes the upper part 7 of the dehydration transmission disc, the lower part 8 of the dehydration transmission disc, the upper part 7 of the dehydration transmission disc is connected with the inner barrel 18, and the lower part 8 of the dehydration transmission disc is connected with the clutch 19 connections, the two can be quickly mated or separated.

Embodiment 3

[0026] The difference between this embodiment and Embodiment 2 is that: the lower surface of the upper part 7 of the dehydration transmission disc is provided with a concave-convex upper hook groove 9, and the upper surface of the lower part 8 of the dehydration transmission disc is provided with a concave-convex lower hook groove 10; Part 7 is connected with the lower part 8 of the dehydration drive plate through the snap-fit rotation connection of the concave-convex upper hook groove 9 and the concave-convex lower hook groove 10 to realize quick engagement or disengagement, and under the condition of rotation, the concave-convex upper hook groove 9 and the concave-convex lower hook The grooves 10 can be snapped into and locked with each other, avoiding the separation of the two during the rotation process, and can quickly replace inner barrels of different volumes and different diameters; the inner barrel 18 can be replaced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com