Dry type single-blade vacuum pump

A single-blade, vacuum pump technology, used in rotary piston pumps, pumps, pump components, etc., can solve the problems of complex structure and inability to use, and achieve the effects of low noise, improved wear resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

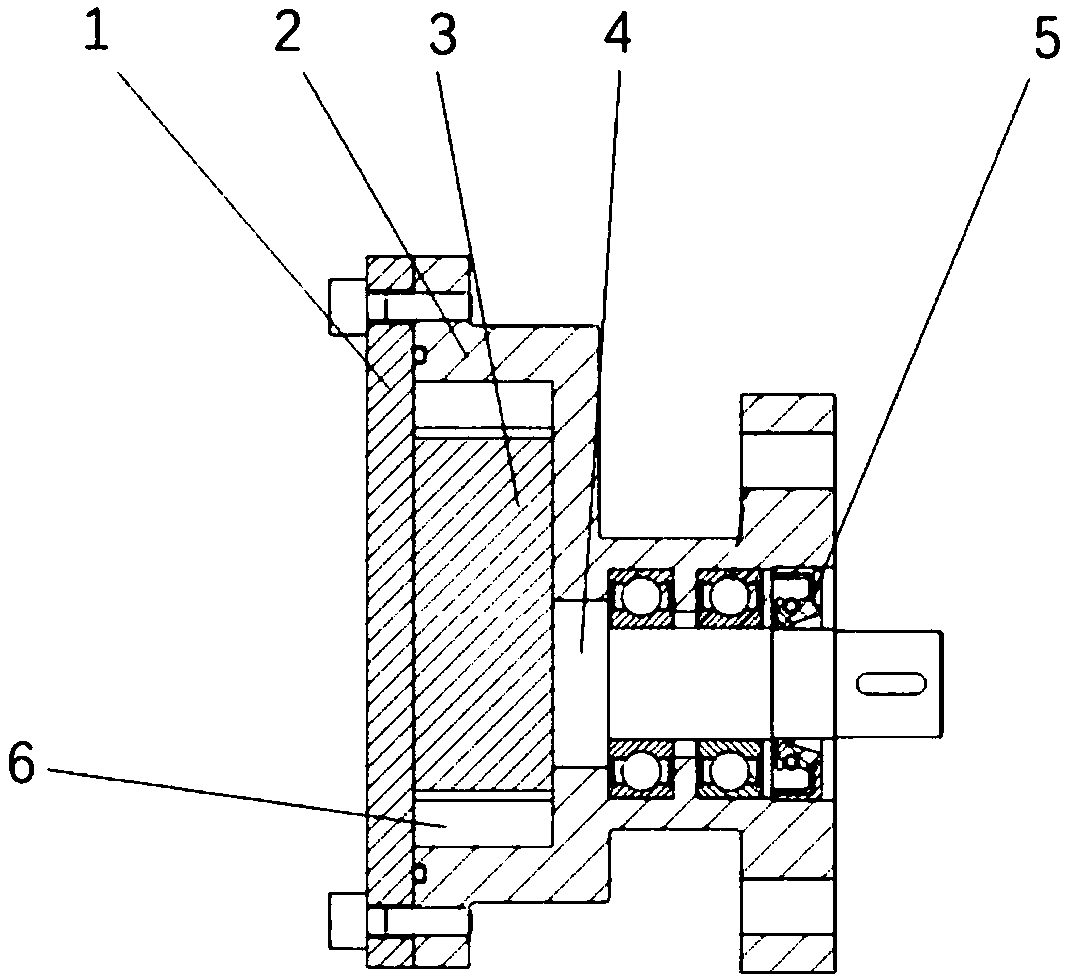

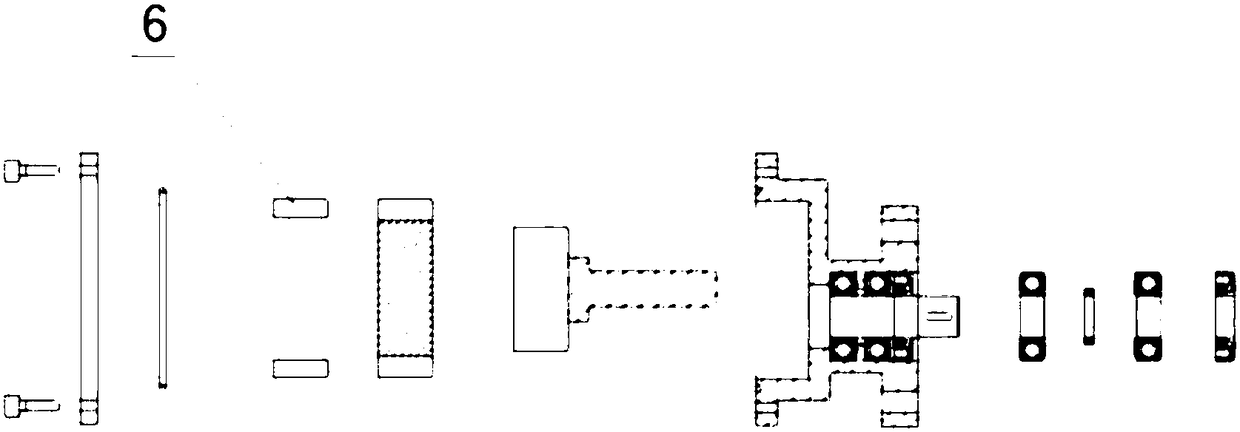

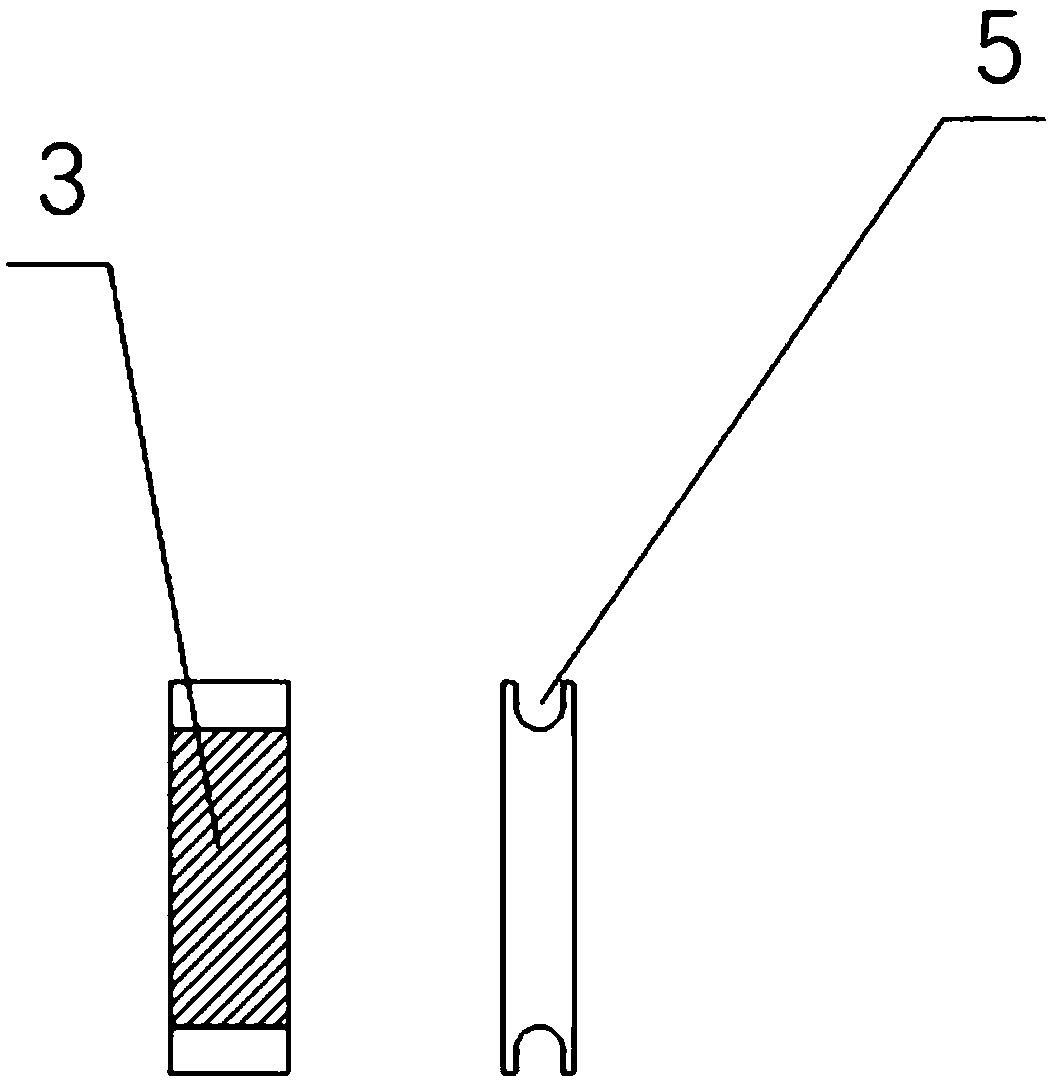

[0021] Such as Figure 1-4 As shown, the dry single vane vacuum pump includes a cover plate 1, a pump body 2, a vane 3, a shaft 4 and a roller 6. The two ends of the vane 3 are processed with a concave arc 5, and the roller 6 is installed in the concave arc 5. The depth of the arc 5 is greater than the diameter of the roller 6, the shaft 4 is installed eccentrically in the pump body 2, a groove and a step are processed on the shaft 4 to install the blade 3 and the roller 6, and the cover plate 1 is installed on the pump body 2 to form a closed pump cavity. Wherein, the inner wall of the pump body 2 is tightly connected with the vane 3 , and the vane 3 gradually moves clockwise from point a to point l on the inner wall of the pump body 2 , that is, the sinusoidal line from point a to point l continuously reciprocates and circulates.

[0022] Such as Figure 5 As shown, when working, when the shaft 4 rotates to drive the blades 3 to rotate, the volume of the pump chamber A inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com