Apparatus for processing graphene pole piece for lithium battery

A processing device and technology for lithium batteries, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of easy friction between the pole piece and the platform, high cost of mold opening, and pole piece offset, etc., to protect the integrity, operate Convenient and well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

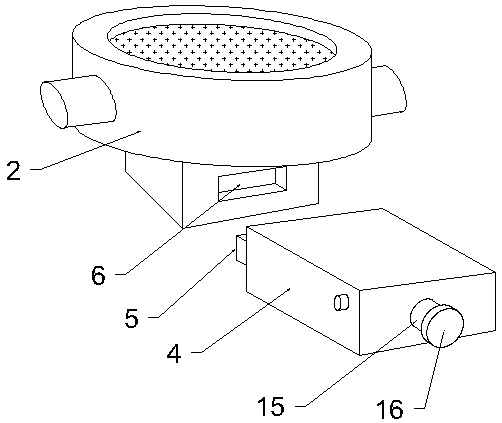

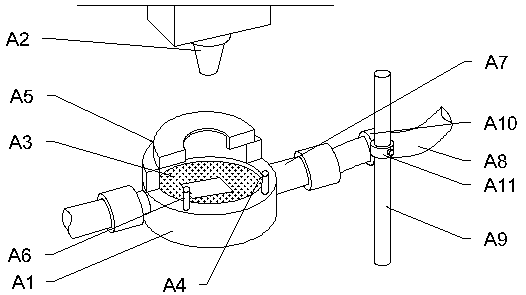

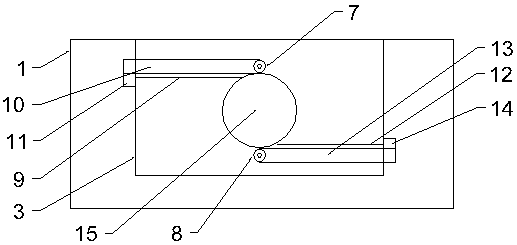

[0010] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach image 3 , the graphene pole sheet processing device for lithium batteries described in this embodiment includes a workbench 1 and a mold 2, wherein the top side of the workbench 1 is provided with a concave installation groove 3, and the outer end opening of the installation groove 3 is formed At the inlet end, the mold 2 is installed on the workbench 1 through the installation groove 3, and the installation groove 3 at the inlet end is provided with a locking assembly, and the installed mold 2 is locked by the locking assembly; the mold 2 includes a base A1 and The processing head A2 located under the base A1, the base A1 is cylindrical, the bottom of the base A1 is equipped with a square base slider, the base slider is located in the installation groove 3, and the lower part of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com