Sand sieving device for building operations

A technology for building construction and sand screening, which is applied in the direction of screening, solid separation, grille, etc., can solve the problems of low efficiency, heavy labor, poor sand screening effect, etc., and achieve the effect of speeding up screening and promoting shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

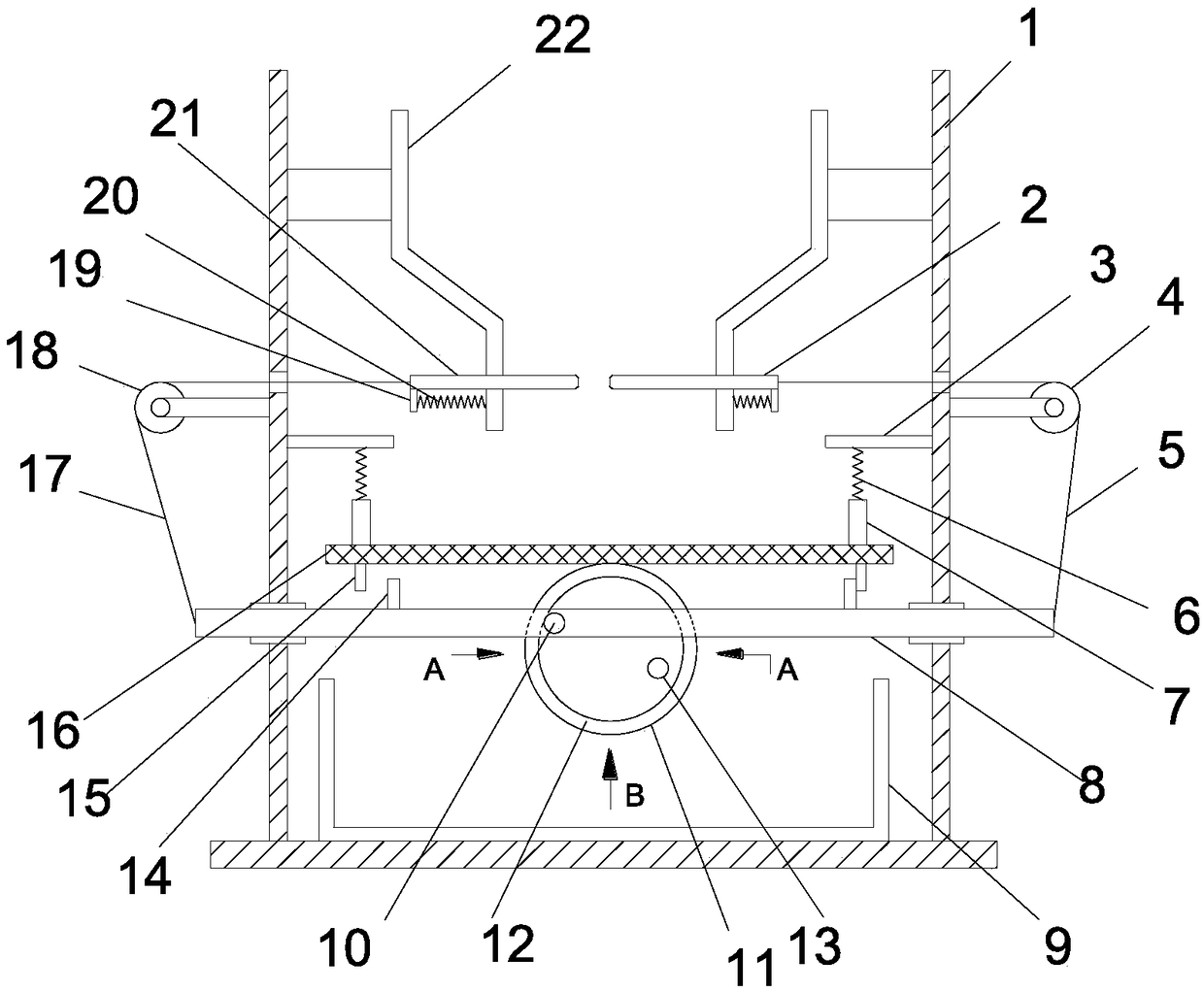

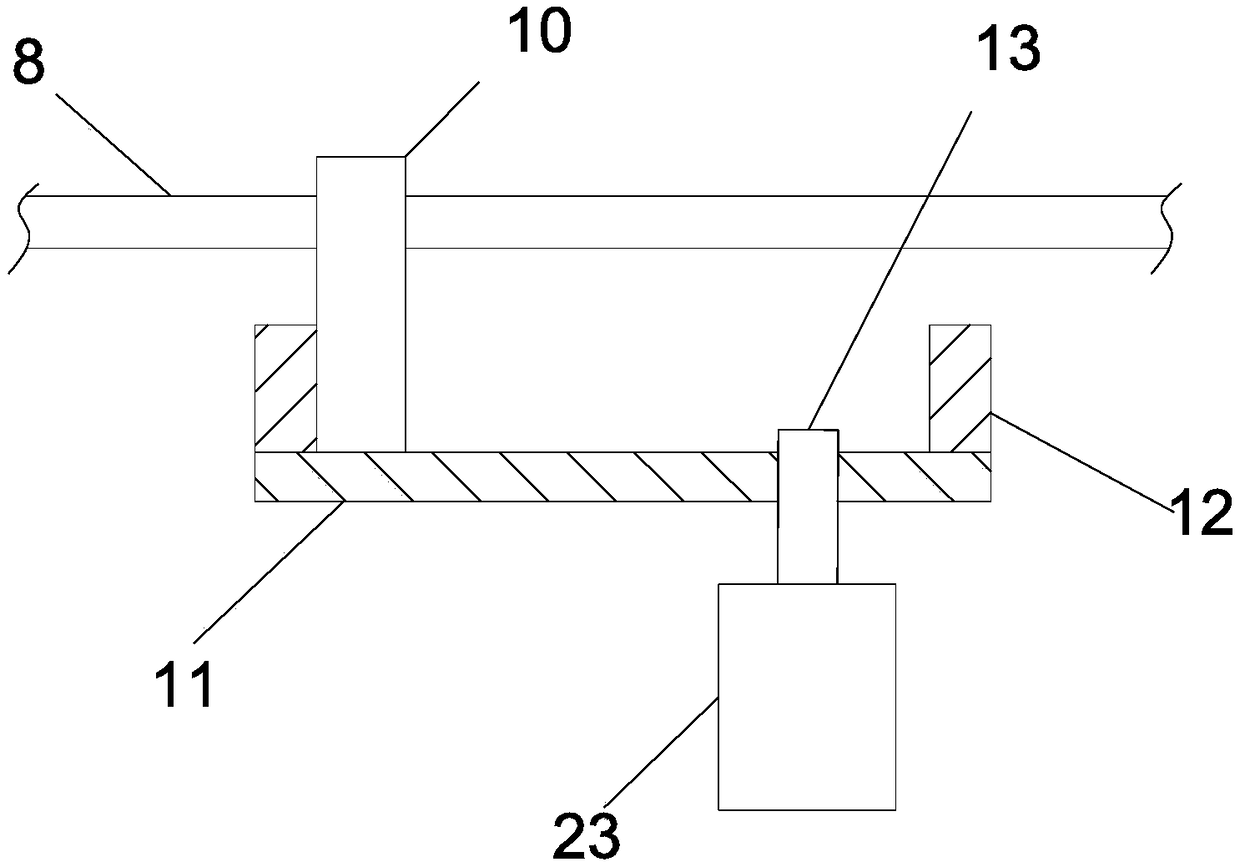

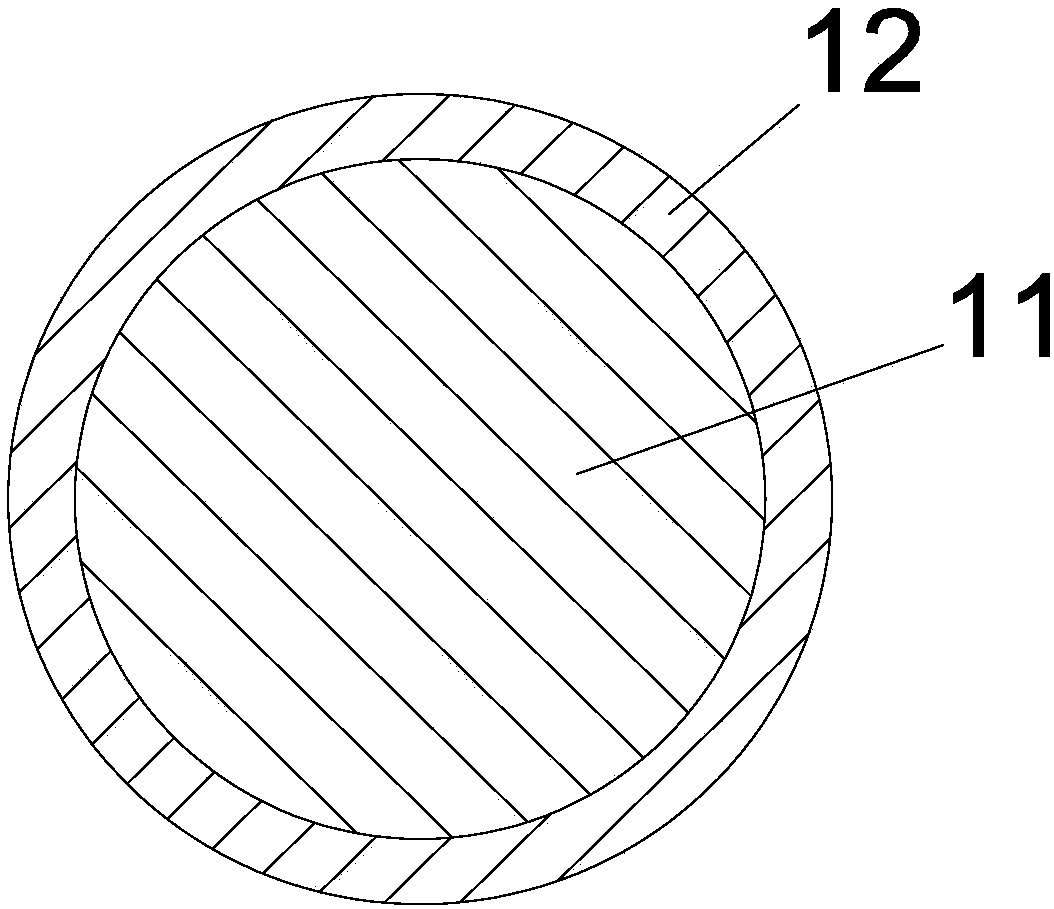

[0021] see Figure 1-3 , a sand screening device for building construction, comprising an operating frame 1, a storage cone bucket 22 is fixedly installed on the upper part of the operating frame 1, a collection tank 9 is fixedly installed on the inner bottom of the operating frame 1, and a horizontal sliding type is installed in the operating frame 1 There is a transmission slide bar 8, a drive motor 23 is fixedly installed on the back of the operating frame 1, an eccentric runner 11 is fixedly installed on the output shaft of the drive motor 23, and a limit transmission collar 12 is fixedly installed on the front of the eccentric runner 11, and a transmission slide bar 8 The pin shaft 10 abutting against the inner surface of the limit transmission collar 12 is fixedly installed on the front side, and an extension plate 3 is fixedly installed horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com