Separator for plastic packaging bag and application of separator to coating package

A packaging bag and divider technology, applied in the field of packaging accessories, can solve the problems of complex operation, material loss, and unusability, etc., and achieve the effects of precise control, reduced loss, and convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

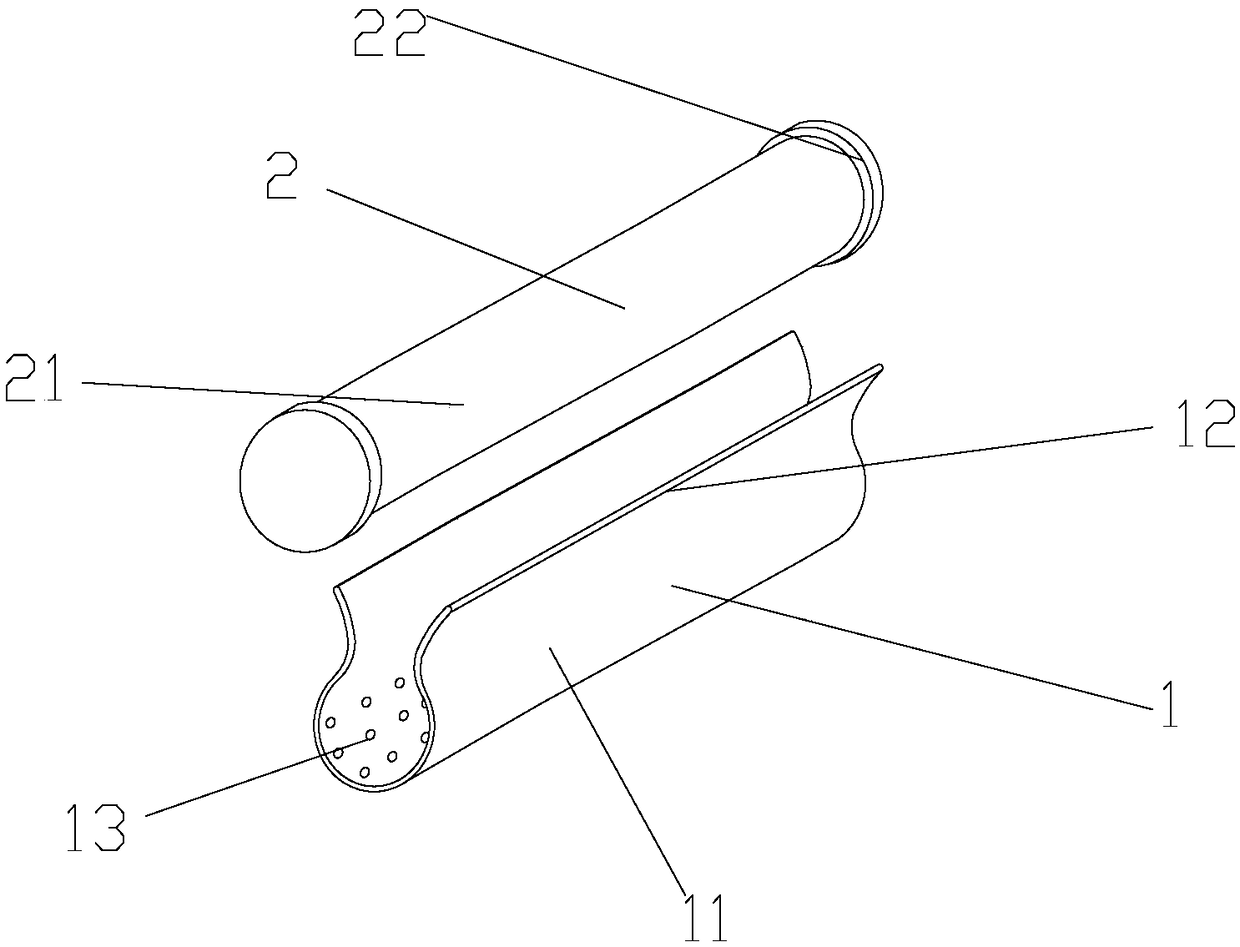

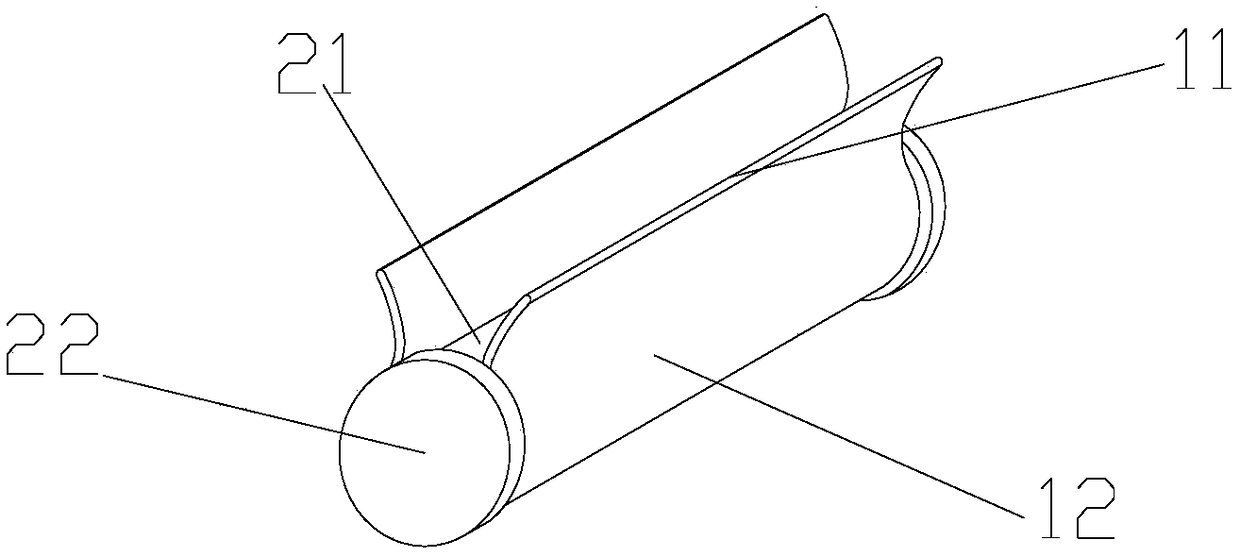

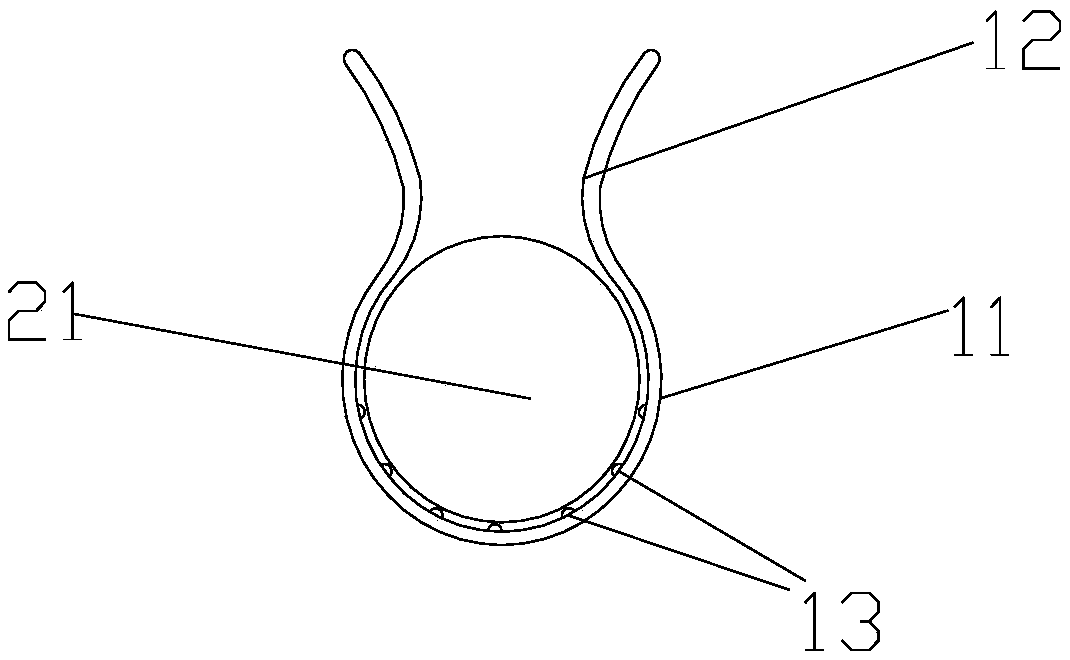

[0020] like Figure 1-3 As shown, a separator for a plastic packaging bag includes a clip seat 1 and a bead 2 sleeved in the clip seat 1. The clip seat 1 is a tubular body with an "Ω" shape in section. The clip seat 1 includes The groove jaw 11 with a circular arc-shaped cross section and the arc-shaped buckle 12 extending outward along the groove jaw 11, the bead 2 includes a rod body 21 and two ends of the rod body 21 extending toward the periphery. Fixed end 22, the rod body 21 is a tubular body with a circular arc in section, the outer edge profile of the rod body 21 is the same as the cross-sectional inner edge profile of the groove jaw 11, the rod body 21 or the groove P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com