Zooming device

A technology for adjusting rings and bodies, applied in installation, optics, instruments, etc., can solve problems such as increased man-hours for damaged products, unsmooth operation of the device, and scratches on the inner cylinder 30 and positioning screws 50

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

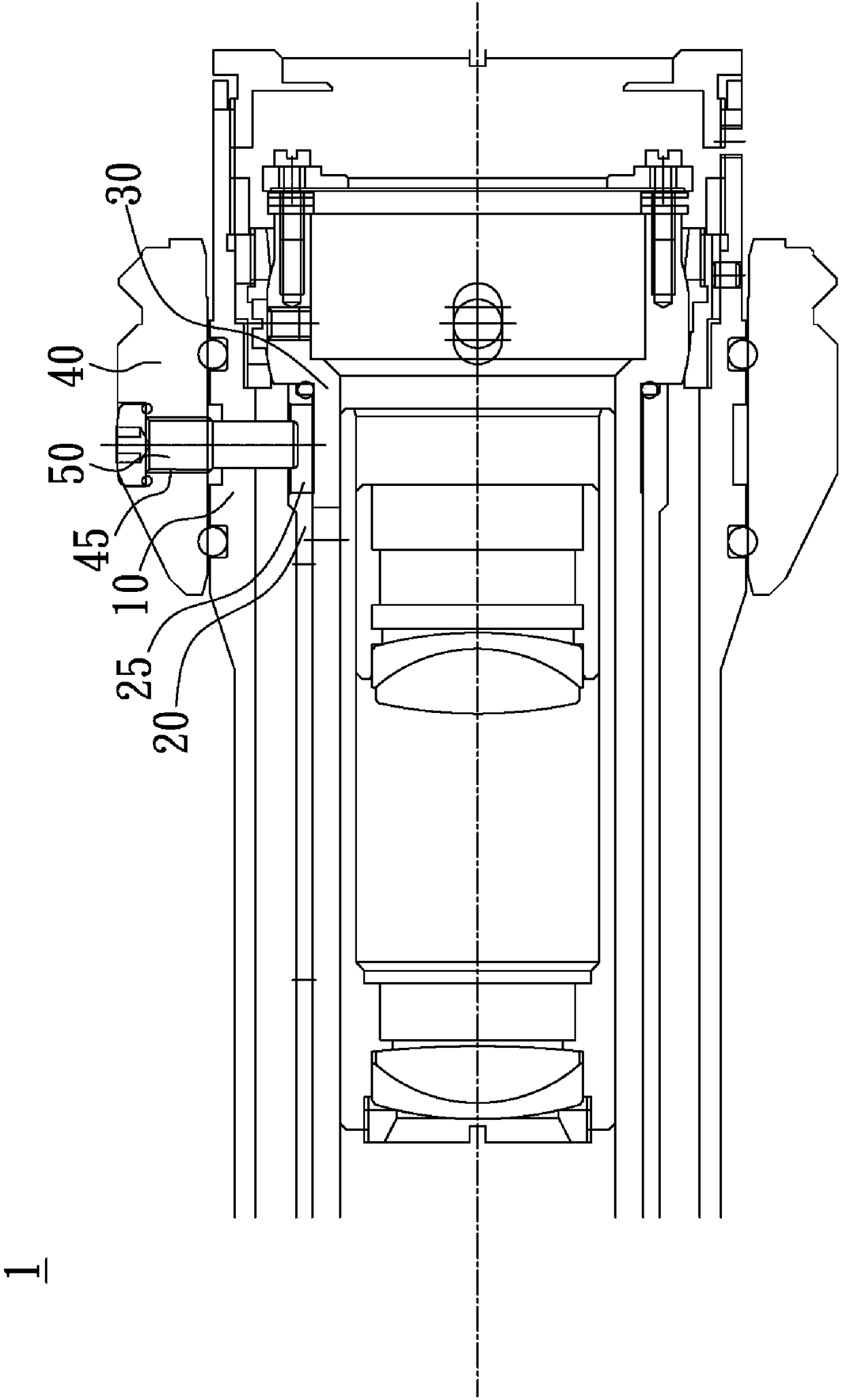

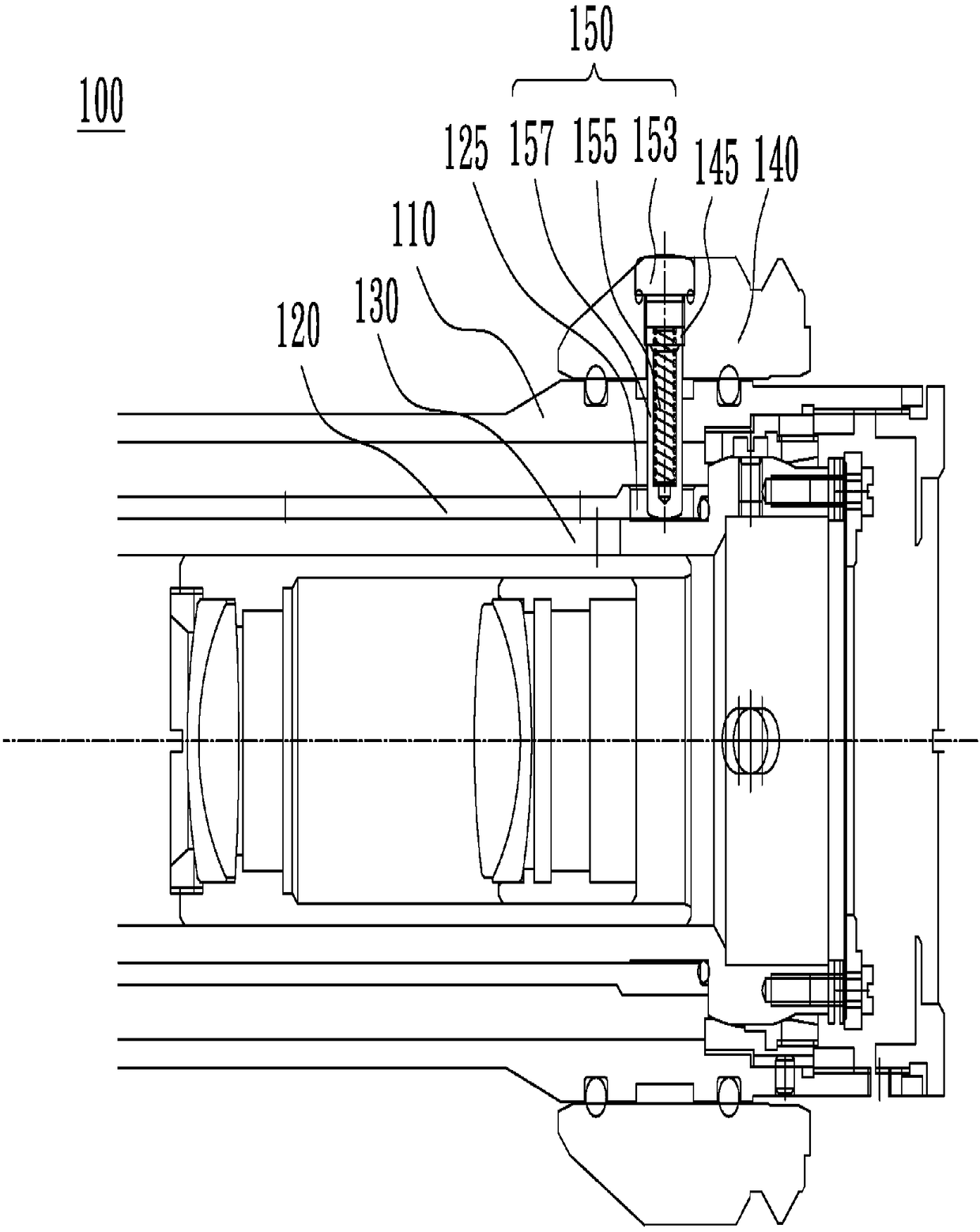

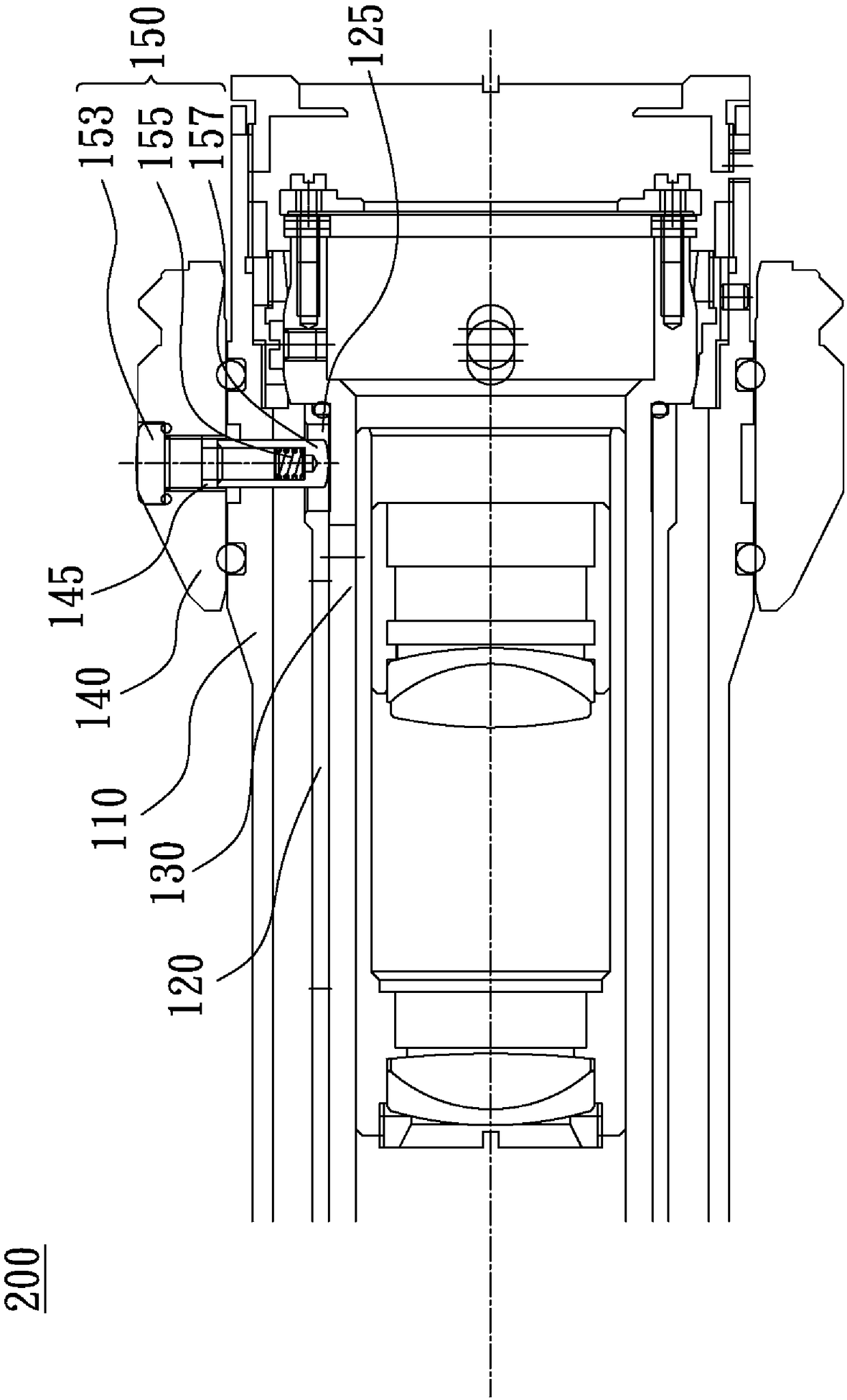

[0027] see figure 2 , figure 2 It shows a structural diagram of one embodiment of the zoom device of the present invention. In this embodiment, the zoom device 100 includes a main body 110, an outer cylinder 120, an inner cylinder 130, an adjustment ring 140 and an adjustment ring positioning member 150, wherein the rotation adjustment The ring 140 can drive the outer cylinder 120 to rotate relative to the body 110 and the inner cylinder 130 . The assembly of these components is detailed below:

[0028] The inner cylinder 130 is disposed inside the body 110 , the outer cylinder 120 is rotatably sleeved outside the inner cylinder 130 , the positioning hole 125 is formed on the outer cylinder 120 , and the adjustment ring 140 is rotatably sleeved outside the body 110 . The adjusting ring positioning member 150 includes a fixing member 153, an elastic body 155 and a positioning cylinder 157. The positioning cylinder 157 can move through the body 110 and the positioning hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com