Soil covering roller

A roller and soil-covering technology, which is applied to the planting method, excavation/covering trenches, interval quantitative sowing machinery, etc., can solve the problems of high cost, inconvenient use, and affecting the depth and accuracy of planting, so as to improve the strength, Guarantee the effect of spotting depth and precision, convenient and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the present invention, the axial direction refers to the axial direction of the entire soil covering drum, and the circumferential direction refers to the circumferential direction of the entire soil covering drum.

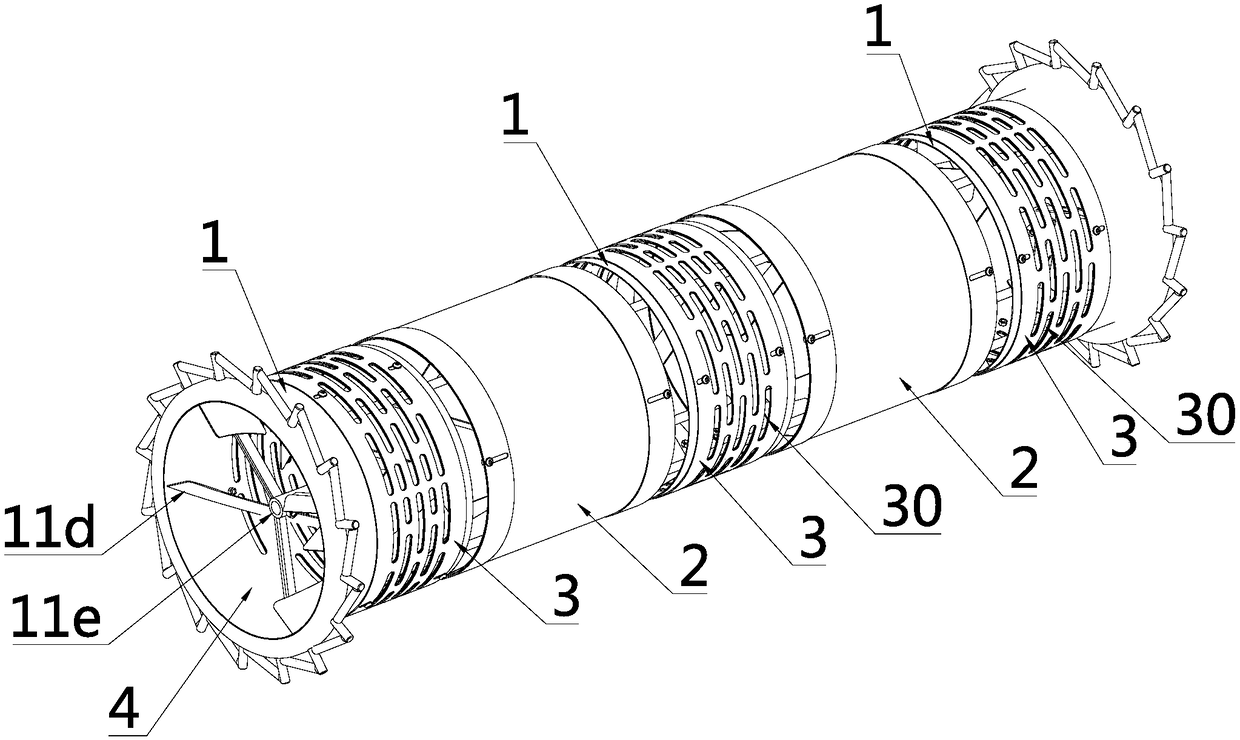

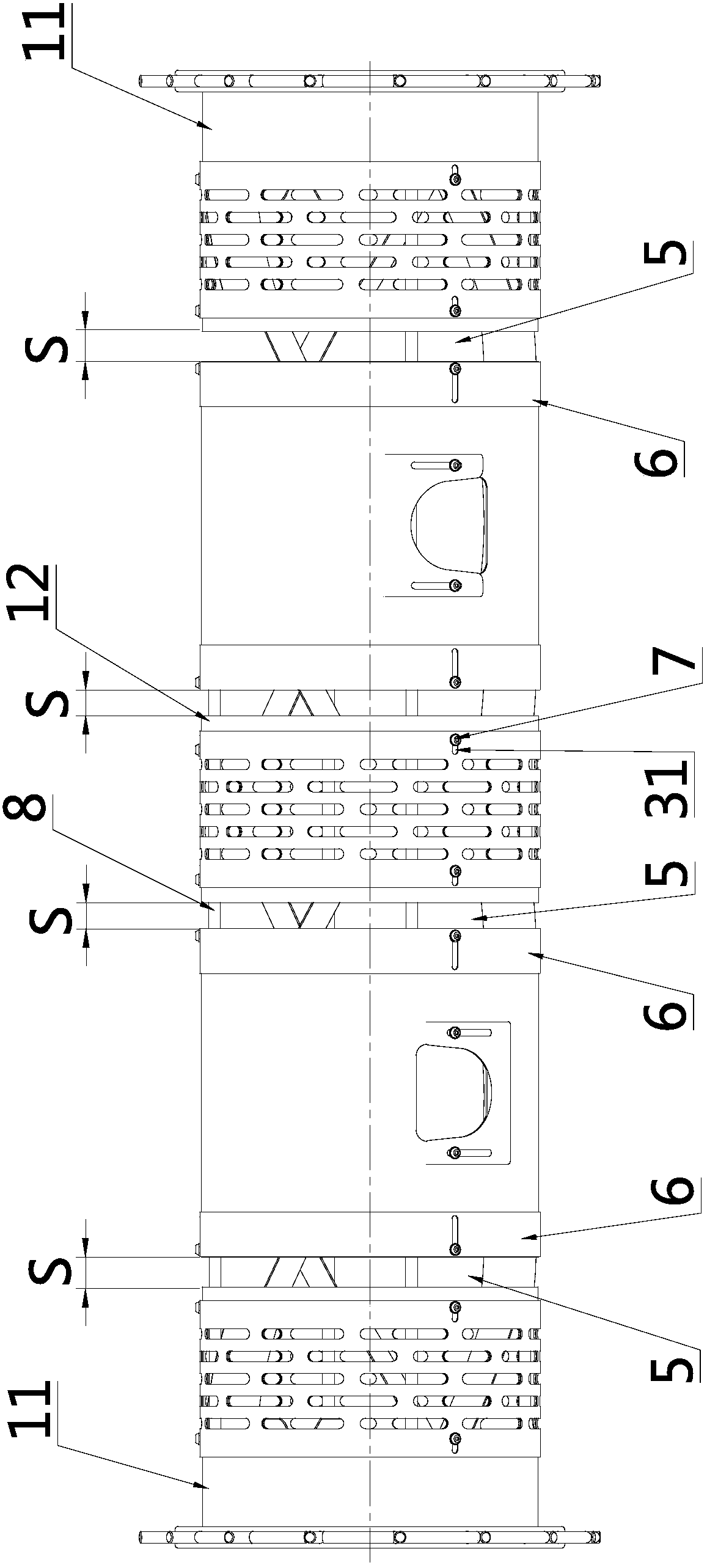

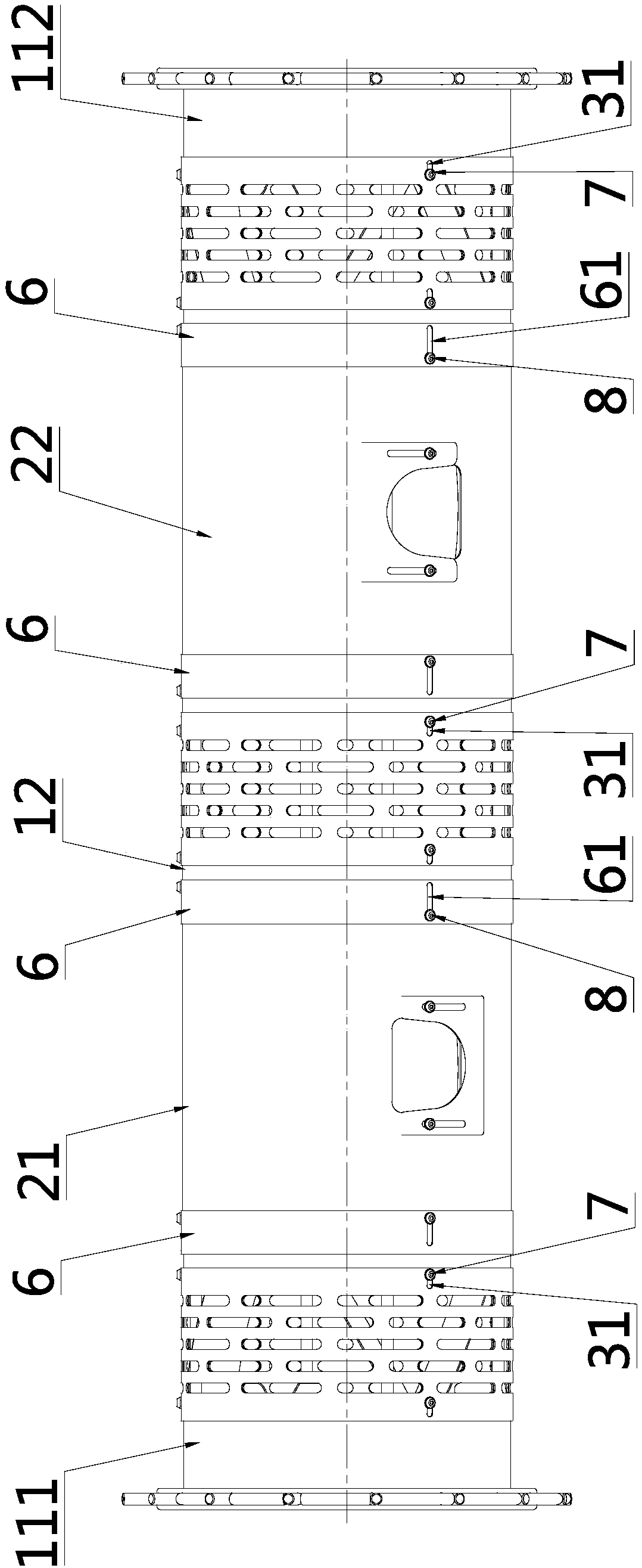

[0030] like figure 1 As shown, the present invention provides a soil covering drum, comprising a cylinder body 1 and a connecting cylinder 2, both ends of the connecting cylinder 2 are connected to the cylinder body 1 to form a soil storage channel 4, and the cylinder body 1 is provided with a The distribution of the first adjustment position and the second adjustment position, the outside of the cylinder body 1 is covered with a surface seal adjustment cylinder 3 with an outer soil hole 30, the surface seal adjustment cylinder 3 slides relative to the cylinder body 1 in the axial direction, and the outer soil hole 30 When the surface seal adjustment cylinder 3 slides axially to the first adjustment position, it communicates with the soil storage passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com