Pneumatic tire

A pneumatic tire and tire technology, applied in the main field of tire shoulders, can solve the problems of reduced driving stability on dry roads, difficult driving stability, driving stability resistance to uneven wear, and reduced driving stability, so as to improve driving stability and uneven wear resistance, improve uneven wear resistance, and avoid rigidity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

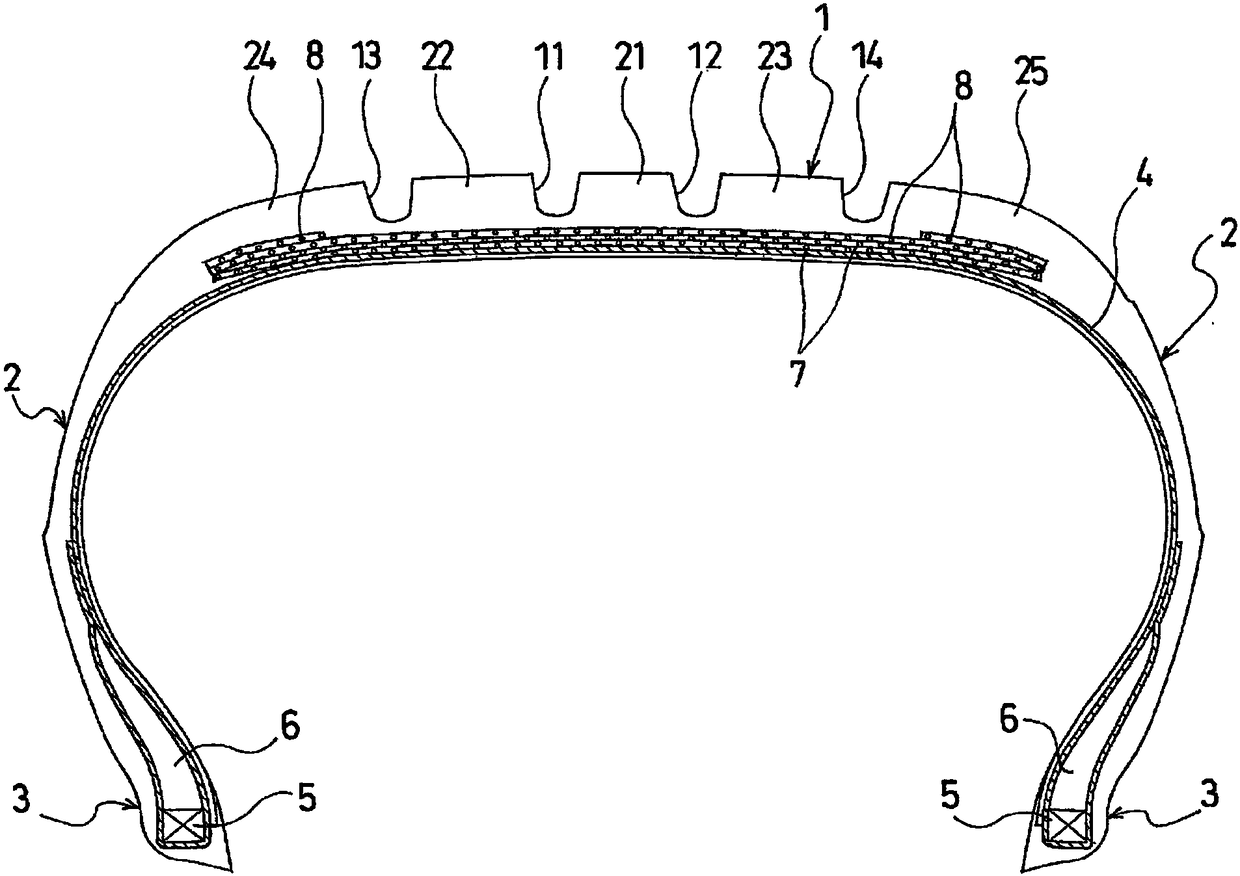

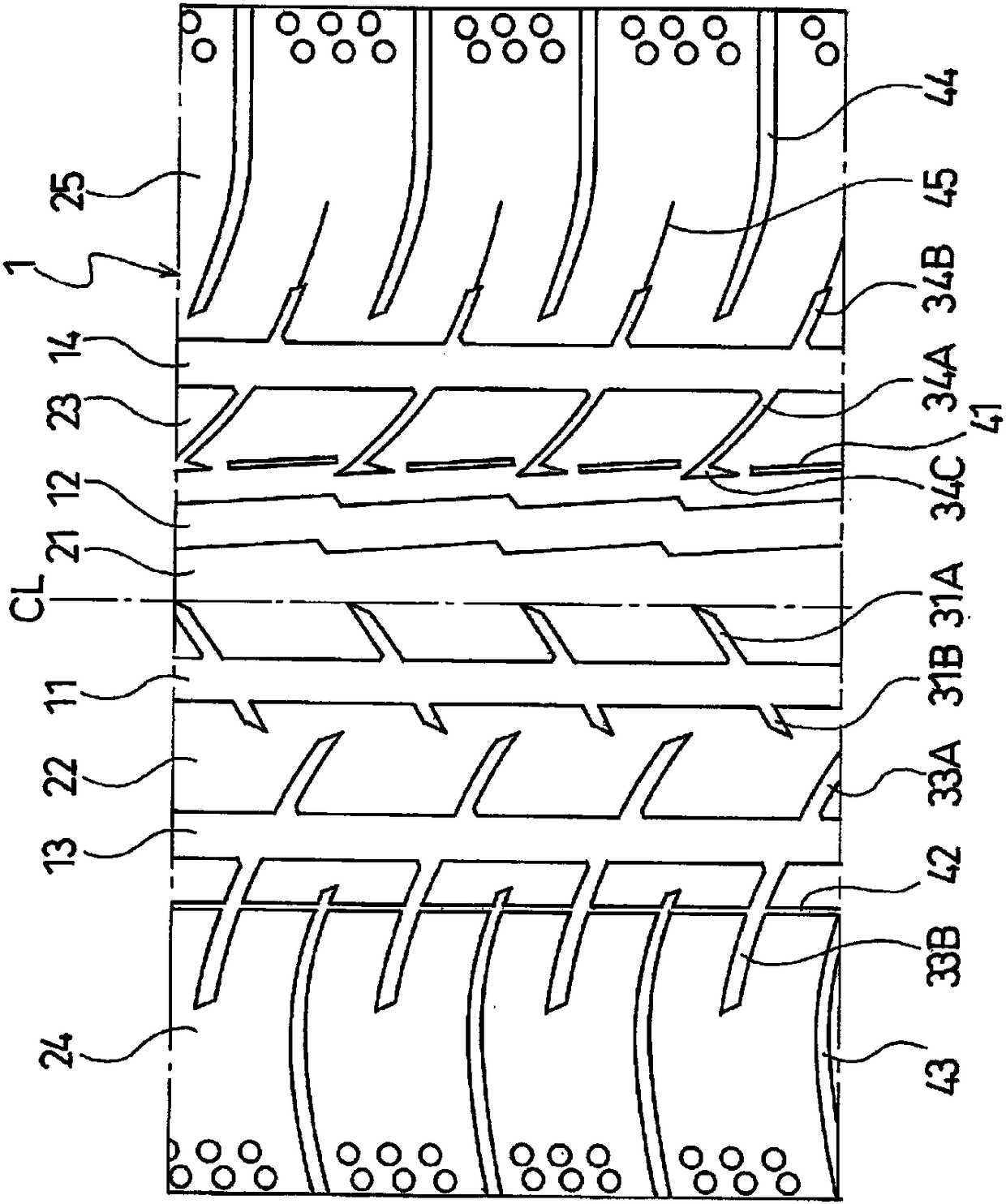

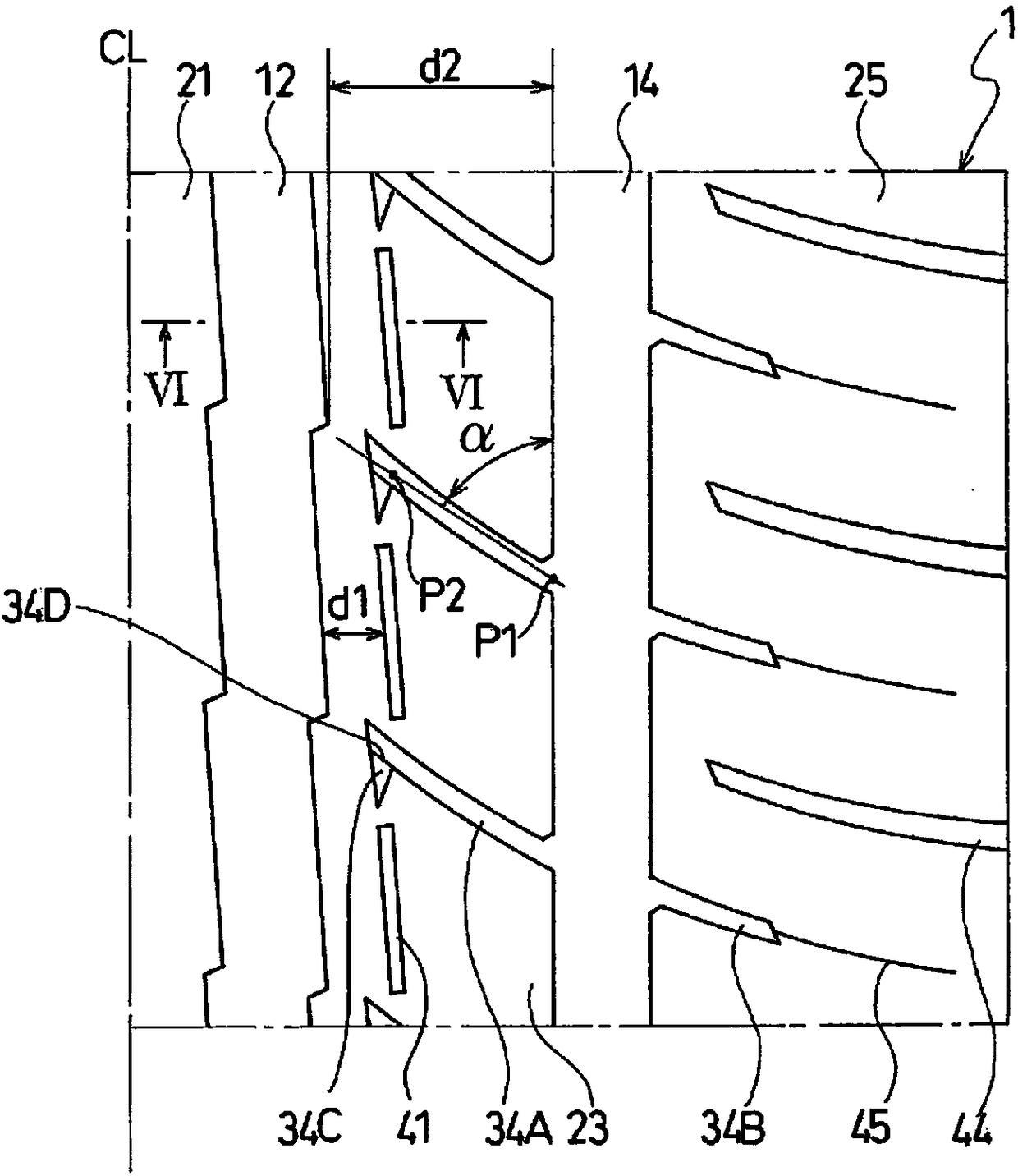

[0047] The following tires of Examples 1 to 9 were manufactured: the tire size was 215 / 55R17, and among the pneumatic tires provided with a tread portion, a pair of sidewall portions, and a pair of bead portions, such as figure 2 As shown, four main grooves including a pair of central main grooves extending in the tire circumferential direction and a pair of shoulder main grooves extending in the tire circumferential direction outside the central main grooves are provided on the tread portion. There are five rows of lands, and one central main groove is zigzag along the tire circumferential direction, and the other main grooves are linear, and the land is located between the zigzag central main groove and the shoulder main groove. A plurality of lug grooves extending from the shoulder main groove toward the inner side in the tire width direction and terminating without communicating with the central main groove form a curved portion that curves toward one side in the tire circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com